K-WANG

Baldor MotiFlex e100 Servo Drive Installation and Configuration Guide

Baldor MotiFlex e100 Servo Drive: Professional Guide to Installation, Configuration, and System Integration

Baldor MotiFlex e100 is a high-performance, multifunctional brushless servo drive suitable for precision motion control of rotary motors and linear motors. It supports multiple feedback interfaces (incremental encoder, BiSS, EnDat, SSI, SinCos), has position, speed, and current control capabilities, and integrates automatic tuning function and rich communication interfaces (USB, Ethernet POWERLINK, CANopen, RS485), suitable for various industrial automation scenarios.

1、 Product Overview and Core Features

The MotiFlex e100 series covers 10 continuous current rated models from 1.5A to 65A, directly supporting 230-480VAC three-phase power input. The driver has a built-in universal feedback interface, which is compatible with multiple encoder types and supports DC Bus Sharing function, reducing the complexity of power wiring in multi axis systems.

Its main characteristics include:

Support position, speed, and torque three loop control

Integrated Auto Tuning Wizard and Software Oscilloscope Function (via Mint WorkBench v5.5)

3 optoelectronic isolated universal digital inputs, 2 of which support high-speed position capture

1 analog input (± 10V)

Supports multiple communication protocols such as Ethernet POWERLINK, CANopen, TCP/IP, etc

Programmable Motion Control Language Mint

2、 Preparation and safety instructions before installation

2.1 Installation environment requirements

The driver should be installed in an indoor electrical cabinet, with an ambient temperature of 0-45 ℃ (can be reduced to 55 ℃) and a humidity of ≤ 93% (non condensing). Ensure that the installation location is away from heat sources, corrosive gases, metal dust, and electromagnetic interference sources.

2.2 Safety Warning

Only professionals with electrical qualifications are allowed to install and debug.

Before powering on, it is necessary to ensure that all grounding/shielding connections are correct.

After a power outage, the DC bus capacitor needs to discharge for at least 5 minutes before it can come into contact with the power terminal.

The motor may generate dangerous voltage due to external mechanical drive and must be reliably grounded.

3、 Hardware installation and wiring

3.1 Mechanical Installation

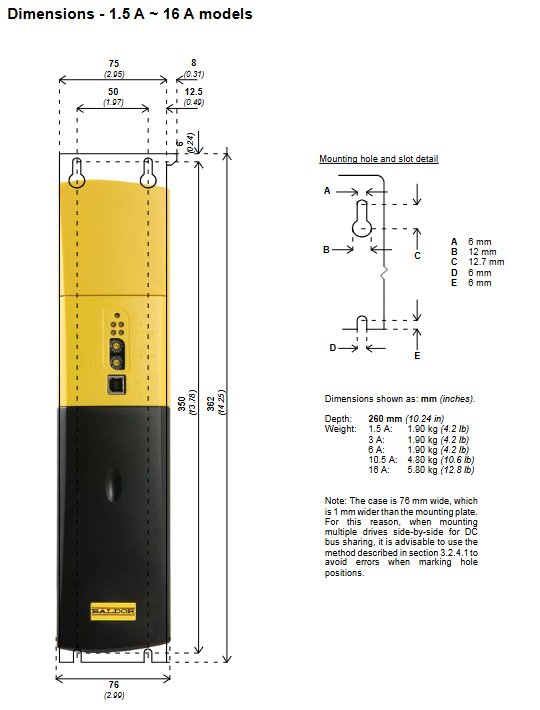

The driver should be installed vertically on a flat metal backplate and secured with M5 screws. The dimensions and weights of different models are detailed in section 8.7 of the manual. Models 48A and 65A are filled with foam on the back, which needs to be removed before installation.

3.2 Power Connection

AC power supply: Connect L1, L2, L3, and PE through the X1 terminal. It is recommended to use Baldor's recommended AC filter and cable filter (see section 3.4.10 for details) to comply with CE/EMC standards.

DC bus sharing: Use the optional OPT-MF-DC series bus kit to connect adjacent drivers, paying attention to the positive and negative pole positions (front positive and rear negative).

Backup power supply for control circuit: 24VDC can be connected through X2 terminal and supports parallel connection of multiple drivers in a "daisy chain" manner.

3.3 Motor and Feedback Connection

Motor power cable: Connect U, V, W, and PE through X17 terminals. The cable needs to be fully shielded, and the shielding layer should be well overlapped with the backplate at the driver end.

Feedback cable: Encoders, Hall signals, etc. are connected through X8 (D-Sub 15 pin). It is recommended to use Baldor original shielded cables, with a maximum recommended length of 30.5 meters.

3.4 Selection and Installation of Regenerative Resistors

Calculate the required braking energy based on the motor inertia, deceleration time, and cycle period, and select appropriate resistors (such as RGJ and RGA series) according to the formula in Section 3.9. Resistors need to be equipped with heat sinks, and attention should be paid to temperature drop and pulse load capacity.

4、 Software configuration and debugging

4.1 Software Installation

Install Mint Machine Center (MMC) and Mint WorkBench (MWB) using the accompanying CD, recommended to run on Windows XP/Vista/7 system.

4.2 Connection between Drive and PC

Supports USB (recommended) or Ethernet TCP/IP connections. If using Ethernet, the IP address of the PC network card needs to be set to the 192.168.100.xxx network segment.

4.3 Commissioning Wizard

Step by step through the debugging wizard in MWB:

Communication settings (node ID, baud rate)

DC bus shared configuration (master/slave driver and "power ready" signal settings)

Motor type and parameter input (supports Baldor motor model or customization)

Feedback resolution setting

Control mode and reference source selection (such as EPL, CANopen, Direct, etc.)

Application limits (peak current, maximum speed, etc.)

Unit scaling settings (position, velocity, acceleration)

4.4 Autotune Wizard

The driver can automatically recognize motor parameters and optimize the control loop. It is recommended to tune without load first, and then perform secondary tuning with load. The speed response can be further optimized through the "fine-tuning" window to suppress overshoot or zero speed noise.

5、 System integration and communication configuration

5.1 Digital I/O Configuration

Drive enable input (X3 pin 9/21)

Universal digital inputs DIN0, DIN1, DIN2 (configurable as error reset, stop, limit, origin, etc.)

Digital outputs DOUT0 (default fault indication), DOUT1 (configurable as brake control, etc.)

5.2 Communication Interface

Ethernet POWERLINK: Supports real-time motion control network, with up to 5 devices connected in a daisy chain.

CANopen: Compliant with DS402 protocol, requires an external 12-24V isolated power supply.

RS485: Supports third-party operation panel access.

5.3 Node ID Setting

Set the EPL network node ID (1-239) through the HI/LO dip switch on the front panel of the driver. CANopen and USB node ID are set in the software.

6、 Fault diagnosis and status indication

6.1 Status LED Description

Green constantly on: running normally

Red flashing: Fault code (flashing frequency corresponds to error type, such as overcurrent, overvoltage, encoder fault, etc.)

Red green alternating flashing: DC bus undervoltage

6.2 Common problem troubleshooting

Communication failure: Check USB/Ethernet connection, IP settings, and node ID conflicts

Driver unable to enable: Check enable input signal and control mode

Motor vibration or overshoot: re execute automatic tuning or reduce control bandwidth

7、 Technical specifications and certification

The MotiFlex e100 meets the following standards:

UL508C, EN61800-5-1 (Safety)

EN61800-3 (EMC, Class C3)

IP20 (up to IP3x after installation)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923