K-WANG

Emerson Motion Control FX 490

Emerson Motion Control FX 490

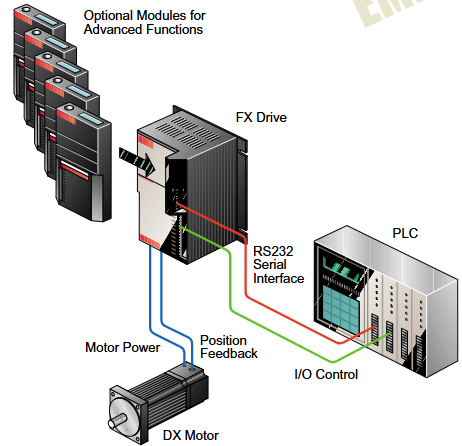

Overview of FX Series Positioning Servo Drive System

The FX series positioning servo drive system is a servo solution with over ten years of application history. By combining FX drivers with PCM modules, it can solve various common applications and is the foundation of the "Motion Made Easy" series solutions. This system is based on the 2000 Emerson Motion Control Servo Solution Catalog information and adopts a fully digital design, suitable for multiple torque ranges. It is compatible with DX series (0-120 lb in) and BL series (120-1000 lb in) rotary transformer feedback servo motors, and some models have UL certification, Canadian UL certification, and CE certification.

Core Features

Flexible power and torque: Supports multiple power inputs and can provide continuous torque from 0-1000 lb in. Some models have IP65 protection and brake versions.

Convenient programming: Use Emerson Motion Control's PCXWin or DOS version PCX software, with fill in the blank operation for easy programming.

Rich I/O and operation modes: Standard equipped with 8 inputs and 4 output lines (10-30 VDC), supporting sinking or sourcing modes; The operating modes include integral locator, simulated speed, simulated torque, and pulse follower.

Scalability: Application modules can be installed to increase I/O, memory, and special application functions. The basic module can start up to 100 steps of motion sequence programs, and adding application modules can reach 1024 steps.

Communication and Storage: Equipped with RS-232 communication interface, with a maximum baud rate of 19.2 Kbaud, it can daisy chain up to 31 FX drives on a single communication link; Non volatile memory can store up to 32 sets of index parameters.

Other features: Supports linear or modified sine motion curves, can be scaled in user-defined units such as inches, feet, millimeters, etc., has auxiliary logic power supply to maintain critical driving information in case of bridge power loss, is equipped with LED display for displaying operation and diagnostic status, and offers a two-year extended warranty.

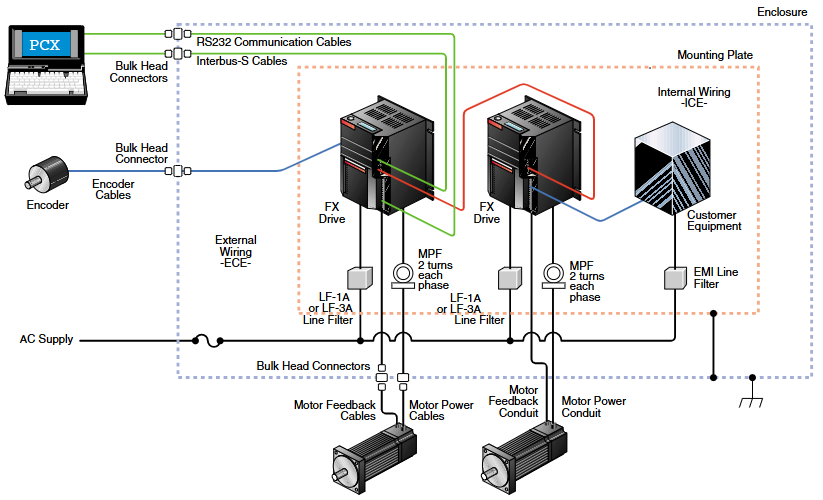

CE marking FX system

Certification and Scope: Compliant with EMC Directive 89/336/EEC and bearing the CE mark, with a continuous torque range of 8-120 lb in, a peak of 200%, and a maximum duration of 1.5 seconds. The amplifier is UL certified and the motor is UL approved, providing complete motion control system components.

Configuration and wiring: The CE marked FX driver has the same functionality and performance specifications as the standard FX driver, and is set using PCX programming software; There are two system wiring methods that meet CE grounding and shielding requirements, both requiring power lines and motor power filters.

Application module

The FX series offers a variety of application modules that can be easily installed on any FX driver front-end, enabling advanced positioning functions such as phase synchronization, proportional control, web control, and rotary tool cutting. It is programmed using the same PCX software as the basic FX driver, with parameters stored in non-volatile memory and movable between different drives. The main application modules include:

PCM-11 motion program controller: suitable for various applications such as composite indexing and packaging machinery.

PCM-14 slip compensator: used for slip compensation, automatic coil feeding and other scenarios.

PCM-15 proportional controller: capable of implementing functions such as flying shears and electronic spools.

Other modules, such as PCM-16 phase synchronization controller and PCM-17 random feed controller, each have their specific application areas.

Operation mode

Position control mode: The microprocessor executes user-defined motion control functions and can store multiple indexes. After adding application modules, the index storage capacity and functions can be expanded.

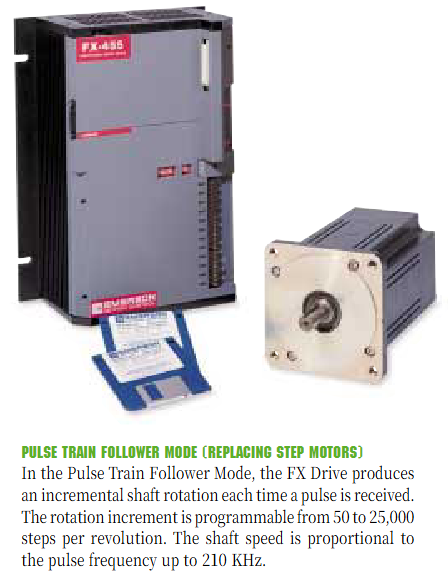

Pulse sequence following mode: Each received pulse generates incremental axis rotation, which can directly replace existing stepper positioning systems.

Simulation mode: includes two options: simulated speed and simulated torque, and all motion and system limitations are effective in this mode.

Software and Programming

PCX programming software: intuitive and simple, no need for advanced programming language knowledge. After the user inputs the motion parameters, the software completes the relevant operations and can complete the system settings in a short time.

Configuration and parameter settings: including driver parameter configuration, motion parameter definition (such as jogging, indexing, etc.), I/O settings, etc.

Specifications and Performance

System specifications: Different models of FX drivers have specific parameters in terms of recommended line current, motor torque, motor rotor inertia, rated power, maximum motor speed, and the shortest time to reach maximum speed.

Brake specifications: Each model of brake has clear data on maintaining torque, inertia, weight, coil voltage and current, engagement and release time, etc.

Driver specifications: including input power supply voltage, control mode, serial interface, programming method, diagnostic indicators, noise immunity, I/O circuit specifications and capacity, resolution, performance, motor housing, environmental specifications, etc.

Options and attachments

Including operator interface terminals, synchronous encoders, serial interface cables, external shunt resistors, main frequency generators, AC line filters, 525 programmable motion controllers, as well as various cables and miscellaneous accessories, it can meet different application needs.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923