K-WANG

Emerson Electric Power Absolute Vibration Sensor (PR 9266/.. And PR 9268/..)

Emerson Electric Power Absolute Vibration Sensor (PR 9266/.. And PR 9268/..)

Sensor Overview

The PR 9266/.. And PR 9268/.. Series electric absolute vibration sensors are designed specifically for measuring the absolute vibration of machines and are part of the MMS 6000 and MMS 3000 rotating machinery monitoring systems. Its working temperature range can reach 200 ° C, using seismic function principle, easy installation, high sensitivity, sturdy structure suitable for industrial applications, with splash proof characteristics, protection level of IP 55 or IP 65, with two frequency ranges of 10 Hz to 1000 Hz and 4 Hz to 1000 Hz. When used in conjunction with safety barriers (Zone 1), the safety level is EEx ib II B/II C.

Application scenarios

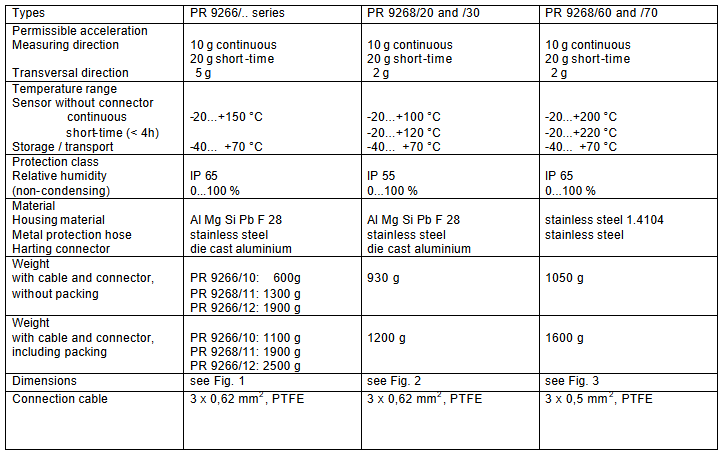

The absolute vibration can be measured in frequency ranges of 10... 1000Hz and 4... 1000Hz, with vibration amplitudes of up to 2mm and 3mm (peak to peak), respectively. It can provide an electrical signal proportional to the vibration velocity. Suitable for various types of turbomachinery, fans, compressors, gearboxes, pumps, coal mills, and other machines. Among them, PR 9268/60 and PR 9268/70 are particularly suitable for high-temperature environments, such as gas turbine applications, and also include electrical adaptation, which can replace the original AEG Kanis Group's MMG 033 and MMG 1033 absolute vibration sensors, and provide three different sensor sensitivities according to the type of measurement amplifier.

Functional Principles and Design

Measurement element: composed of seismic mass blocks with coils, suspended on diaphragm springs, moving in the circular gap of permanent magnets, and guided by diaphragm springs in the longitudinal direction (measurement direction) of the measurement element.

Working mode: The sensor operates above the resonance frequency (different models have resonance frequencies between 4 and 13 Hz), while the seismic mass remains stationary. Due to the vibration of the sensor housing, an electrical signal proportional to the vibration velocity is generated.

Damping: The damping of the measuring element is achieved through a damping cylinder or external device, with a damping value of about 0.6 and good linear characteristics throughout the entire frequency range.

Special design: Measurements below the resonance frequency can be corrected by corresponding amplitude response; When the vibration amplitude is too high, the mechanical limiter will reduce the maximum amplitude of the seismic system; Each sensor is designed for a measurement direction (vertical or horizontal). The PR 9266/.. Series sensor has an additional lifting coil, which adjusts the center position of the seismic element by inputting a lifting current of up to 7mA into the coil; The PR 9268/.. Series sensors can directly input the boost current into the measurement coil, but this current must be separated from the measurement signal. The measurement amplifier of MMS 6000 supports the operation of absolute bearing vibration sensors and provides boost current.

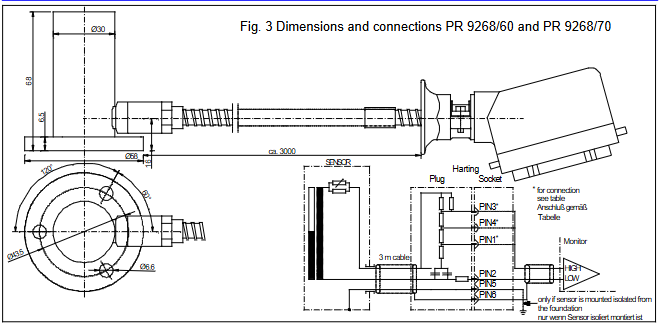

Technical parameters

Parameter PR 9266/.. Series: PR 9268/20 and/30 PR 9268/60 and/70

Measurement principle: Low tuning system for absolute vibration measurement

Electromechanical Conversion: Electric Power, Electric Power, Electric Power

Operation direction: vertical (with lifting current), horizontal (without lifting current) PR 9268/20: ± 10 °; PR 9268/30: ± 10 ° PR 9268/60: ± 60 ° (specified data deviation ≤ 15%); PR 9268/70: ± 30 ° (specified data deviation ≤ 15%)

Frequency range:... 1000 Hz 4... 1000 Hz 10... 1000 Hz

Vibration amplitude (peak to peak) and limiter position: 2000 µ m, limiter at ± 1500 µ m 3000 µ m, limiter at ± 2000 µ m 3000 µ m, limiter at ± 2000 µ m

Natural frequency (20 ° C): Horizontal direction: 12.0 Hz ± 2 Hz; Vertical direction (lift coil activated): 12.3 Hz ± 2 Hz; Vertical direction (lift coil not activated): 14.5 Hz ± 1.5 Hz Horizontal direction: 4.5 Hz ± 0.5 Hz; Vertical direction: 4.5 Hz ± 0.5 Hz When undamped: 10 Hz ± 1 Hz; Horizontal direction: 8 Hz ± 1 Hz; Vertical direction: 8 Hz ± 1 Hz

Sensitivity and conditions: 30 mV/mm ⁻¹ at 50 Hz, 20 ° C, and 100 kOhm load; 28.5 mV/mm ⁻¹ at 50 Hz, 20 ° C, and 100 kOhm load; 22 mV/mm ⁻¹ at PIN 3 and 100 kOhm load; 16.7 mV/mm ⁻¹ at PIN 1 and 50 kOhm load; 16.7 mV/mm ⁻¹ at PIN 4 and 20 kOhm load

Tolerance: ± 3%<± 5.25% ± 5%

Linear error:<2%<2%<2%

Lateral sensitivity:<0.03 (at 50 Hz) PR 9268/20:<0.27; PR 9268/30:<0.13 (at 110 Hz)<0.1 (at 80 Hz)

Damping coefficient (20 ° C/100 ° C): approximately 0.6/approximately 0.43, approximately 0.56/approximately 0.42, measured at PIN 3, approximately 0.7/approximately 0.5 (at 200 ° C)

Effective capacitance (including cable):<2.5 nF<1.2 nF<2.0 nF

Measurement of coil electrical data (DC resistance/inductance): 1800 Ohm ± 12% (including calibration coil); Measurement coil ≤ 62 mH, lifting coil ≤ 75 mH 1875 Ohm ± 2% (including internal resistance); ≤68 mH PIN 3:2760 Ohm±10%; PIN 1:3260 Ohm±10%; PIN 4:3180 Ohm±10%; ≤200 mH

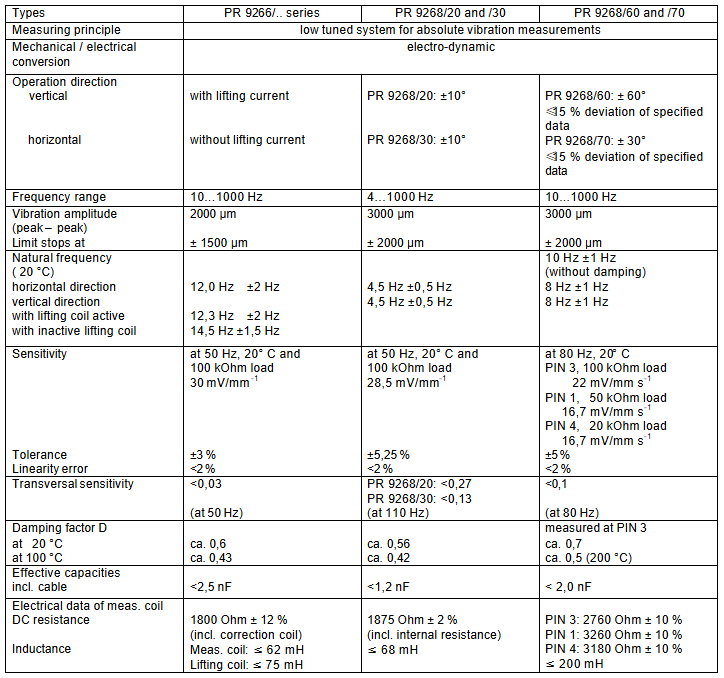

Allowable acceleration (measurement direction/lateral): 10 g continuous, 20 g short-term/5 g 10 g continuous, 20 g short-term/2 g 10 g continuous, 20 g short-term/2 g

Temperature range (sensor without connector, continuous/short time (<4h)/storage and transportation): -20...+150 ° C/-20...+170 ° C/-40...+70 ° C -20...+100 ° C/-20...+120 ° C/-40...+70 ° C -20...+200 ° C/-20...+220 ° C/-40...+70 ° C

Protection level/relative humidity (non condensing): IP 65/0... 100% IP 55/0... 100% IP 65/0... 100%

Materials (shell/metal protective hose/Hart connector): Al Mg Si Pb F 28/stainless steel/die cast aluminum Al Mg Si Pb F 28/stainless steel/die cast aluminum stainless steel 1.4104/stainless steel/die cast aluminum

Weight (with cables and connectors, unpackaged/including packaging): PR 9266/10:600g/1100g; PR 9266/11:1300g/1900g; PR 9266/12:1900g/2500g 930g/1200g 1050g/1600g

Connecting cable: 3 x 0.62 mm ², PTFE, 3 x 0.62 mm ², PTFE 3 x 0.5 mm ², PTFE

Ordering Instructions

The order model format is PR 926X/X-XX0, and the meanings of each part are as follows:

The PR 9266 series corresponds to the number "6", and the PR 9268 series corresponds to the number "8".

Base type: 0 for no base, 1 for triangular base, 2 for cubic base.

Measurement direction: PR 9268/20 is vertical, PR 9268/30 is horizontal, PR 9268/60 is vertical (high temperature 200 ° C), PR 9268/70 is horizontal (high temperature 200 ° C).

Cable length: 0 is 3m, 1 is 5m, 2 is 8m, and 3 is 10m.

Cable end (only PR 9268/60 and/70 with Hart connector): 0 is Hart connector, 1 is open cable end.

Flexible metal protective tube: 0 with strap, 1 without strap.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923