K-WANG

ABB Freelance 800F Compact Control System

ABB Freelance 800F Compact Control System

Product overview

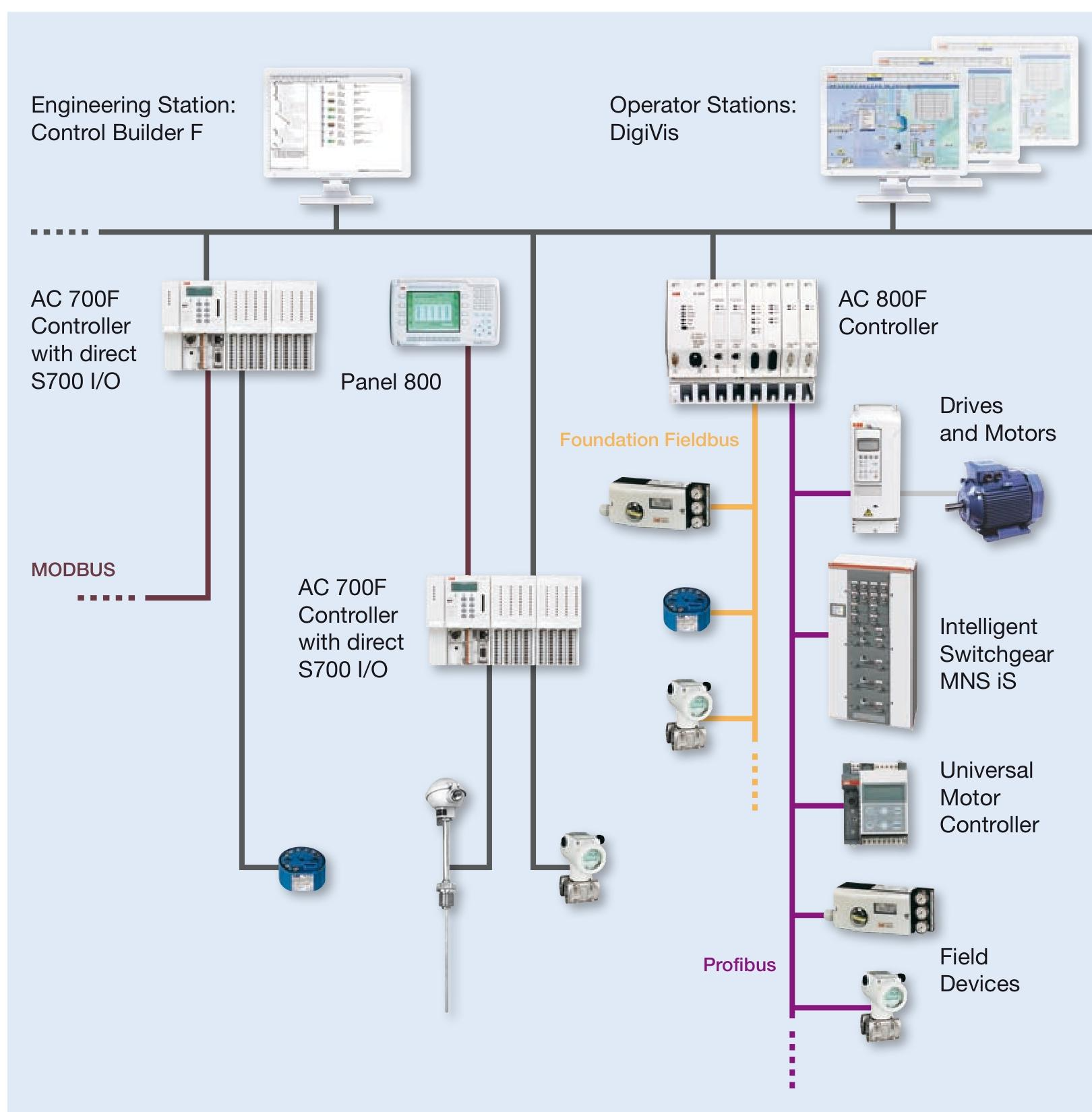

Freelance 800F is a compact and scalable control system launched by ABB, integrating traditional process control technology with enterprise management functions. Its design goal is to achieve high automation at low cost, and it has over 10000 application cases worldwide, covering various industrial fields, especially suitable for scenarios such as power, process or environmental technology factories. This system combines cost-effectiveness of hardware and software, and is easy to use, meeting the diverse needs of projects from small to medium-sized.

Core controller

AC 700F controller

Features: It is a miniaturized process station that can be directly connected to S700 I/O modules, with a compact size.

Applicable scenarios: Suitable for small applications with 16 to 256 I/O points, expanding the application range of Freelance 800F.

Function: It has excellent functionality and usability, supports system expansion, has the same powerful engineering options and convenient visualization capabilities as AC 800F, consistent engineering tools, including DigiVis operating interface, pre configured visualization components, etc., which can be used directly and reduce manual configuration time.

AC 800F controller

Features: As a process station, it can handle process and diagnostic data from up to four fieldbus gateways, with a compact and robust design.

Applicable scenarios: It is suitable for installation in control rooms and can also be used for on-site junction boxes, capable of handling multiple types of fieldbus.

Engineering and Configuration

Engineering Tools: Control Builder F is used as the only engineering tool that supports consistent configuration, debugging, and diagnostics from graphics to field devices, providing all five programming languages specified in IEC 61131-3.

Equipment integration: By using FDT/DTM technology to integrate on-site equipment, there is no need for tedious GSD file integration. The graphical parameter setting dialog boxes (DTMs) provided by equipment manufacturers can transmit specific signals and parameters to control system engineering tools, while completing the main equipment configuration. Most important on-site equipment has corresponding DTMs.

On site layer and communication

On site equipment connection: ABB provides a wide range of on-site equipment that can be easily integrated into the process layer through mature communication standards. With the help of Profibus, remote I/O can be achieved by connecting to the AC 800F controller. The S800 and S900 I/O systems can connect a large number of sensors and actuators.

Fieldbus support: Supports multiple important fieldbuses, including PROFIBUS-DPV1/PA, FOUNDATION Fieldbus HSE/H1, HART (via remote I/O), MODBUS master-slave mode, CAN for Freelance Rack I/O, and remote protocol IEC870-5-101. A single AC 800F controller can run multiple fieldbuses in parallel.

Operational layer and scalability

Operation interface selection

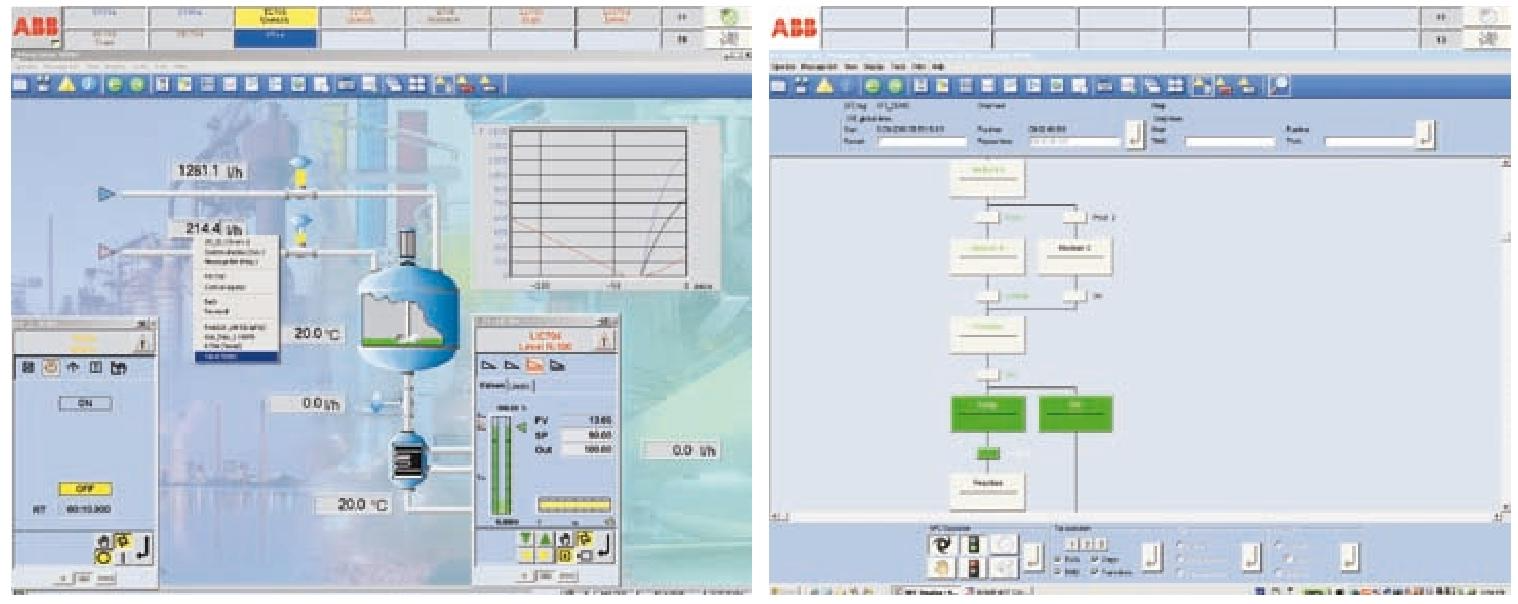

DigiVis: Moderately priced to meet the standard requirements of process operation and monitoring, supporting dual screen operation, free graphic display, structured operation panel, trend display, hardware diagnostic system display, alarm page, etc. The configuration is fully integrated into Control Builder F, and optional batch packages based on 800xA Batch Management can also be integrated. When using PGIM 800F, advanced information management functions can be obtained.

800xA Operations: Provides more advanced operational functions, supports four screen operation, client server architecture (up to 40 workstations), can integrate multiple Freelance island groups into one interface, and can also integrate batch management and 800xA information management functions. It also supports other interfaces such as Power Generation Portal, SCADAvantageTM, Conductor NT.

Technical transition flexibility: Users can freely choose the transition time from traditional 20mA instruments to digital fieldbus technology, and can run traditional I/O modules and fieldbus devices in parallel, gradually replacing old devices.

System advantages

High availability: After years of industrial application verification, it can meet strict availability requirements, and hardware redundancy can be achieved at all levels, including fieldbus device gateways, networks, controllers, control layers, and bus systems.

Scalability: It can be adapted from small 8-point systems to large systems with over 10000 points, and can be expanded at any time to meet requirements.

Multi functional communication: supports OPC, Ethernet TCP/IP、PROFIBUS、FOUNDATION Fieldbus、MODBUS、HART It also has the functions of alarm voice output, video integration and Internet connection.

Compliance: To meet the requirements of regulatory agencies such as FDA and EFSA, features such as encrypted logs and trend data, audit tracking functionality, access permissions, and user management (security locks) are provided to facilitate the verification process.

Lifecycle management: Through the Automation Sentinel program, control software updates can be maintained, the latest system software versions can be obtained in a timely manner, improving productivity, reducing support costs, and simplifying software management. Upgrading from traditional control systems to Freelance 800F can improve usability and reduce maintenance costs.

Asset management: The control system and related databases provide necessary information on equipment availability and wear and tear, supporting modern asset management methods. Through asset optimization, process analysis is conducted to achieve efficient maintenance and optimization, and to improve capacity utilization.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB AX411/511010/STD pH/ORP Analyzer Controller

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923