K-WANG

SIEMENS G120 CU240BE-2 frequency converter

SIEMENS G120 CU240BE-2 frequency converter

Detailed analysis of parameter system

(1) Basic rules for parameters (supplementary configuration logic)

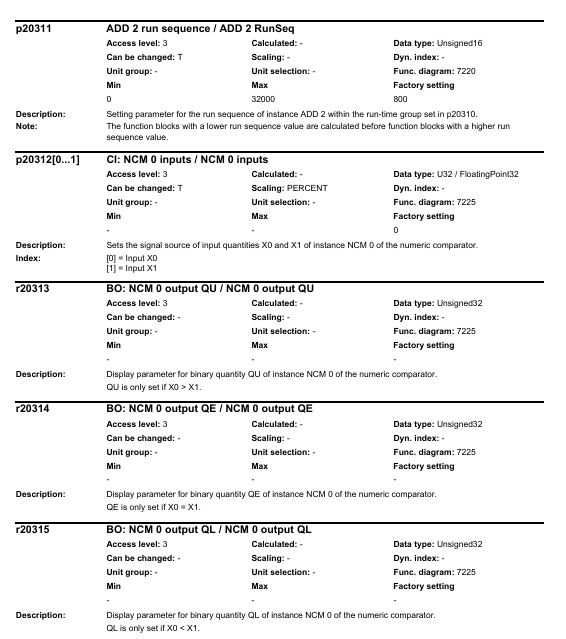

Parameter number and type

Number format: Read and write parameters starting with "p" (such as p0003), read-only parameters starting with "r" (such as r0002, displaying the running status of the driver);

Index identifier: with [0... n] indicating multiple index parameters (such as p0304 [0... n], supporting storage of multiple motor parameters);

Bit field identifier: with. 0... n represents bit parameters (such as r0046.0, corresponding to the switch status of specific functions).

Parameter access and modification rules

Access level control: Set through P0003, Level 3 (expert level) includes 1-2 levels of functionality, and Level 4 (service level) requires a password (p3950) to unlock;

Modification effective conditions: Some parameter annotations "C (x)" indicate that they can only be modified in debugging mode (p0010=x), "U" indicates that they can be modified during operation, "T" indicates that they can be modified in the ready state, and some parameter modifications require restarting the frequency converter to take effect;

The impact of associated parameters: The "Linked parameterization" feature automatically synchronizes the modification of associated parameters when modifying some parameters (such as p0922 PROFIBUS telegram), and the impact range needs to be confirmed in advance.

(2) Detailed analysis of core parameter module

1. Basic configuration parameters (p0000-p0999)

Parameter Number Parameter Name Core Function Value Range Default Values Key Explanation

The parameter range that can be viewed/modified in the access level control of P0003 is 3 (expert), 4 (service), and 3/4. The password p3950 is required for level 4, and only authorized service personnel can operate it

P0010 Debugging parameter filter filters visible parameters at different debugging stages 0-95 1 0=ready, 1=fast debugging, 3=motor debugging, 15=dataset configuration, 30=parameter reset, 95=safety integration debugging

P0015 Driver Unit Macro Run Preset Macro File, Quickly Configure Typical Application Scenarios 0-999999 7 (CU240B-2)/12 (CU240E-2) After Execution, Parameter Lock, R3996=0 is Required to Modify Again

P0096 Application class switching control view (adapted to different application scenarios) 0=Expert, 1=Standard drive control, 2=Dynamic drive control 0 1=Suitable for standard loads such as pumps/fans, 2=Suitable for high dynamic response loads (such as machine tools)

P0100 Standard Selection (IEC/NEMA) Switching Motor Parameter Unit System 0=IEC, 1=NEMA, 2=NEMA+SI 0 0=Power Unit kW, Frequency 50Hz; 1=Power Unit hp, Frequency 60Hz

P0170 Command Dataset Quantity (CDS) Configuration: The number of storable command datasets is 2-4. 2 Supports quick switching of different control commands (such as manual/automatic frequency source switching)

P0180 Driver Dataset Quantity (DDS) Configuration: The number of storable driver datasets ranges from 1 to 4, and supports fast switching of different motor or load parameters (such as multiple motors sharing a frequency converter)

2. Motor parameters (p0300-p0399)

The core is used to match the motor nameplate data, which directly affects the control accuracy and protection function, and is a key debugging step:

Parameter Number Parameter Name Core Function Value Range Default Values Key Explanation

P0300 Motor type selection definition: Motor type 0=no motor, 1=induction motor, 2=synchronous motor, etc. After selecting 0, the corresponding motor parameters will be automatically filtered. If the synchronous motor does not display the exclusive parameters of the induction motor

P0301 motor code number: Select motor model 0-65535 from the built-in motor parameter list. 0=manually input parameters,>0=load preset parameters from Siemens motor database

The rated voltage input on the motor nameplate of P0304 motor is 0-20000 Vrms, which needs to be matched with the supply voltage. When connected in a star/delta configuration, it needs to be adjusted accordingly (such as the delta connection voltage being √ 3 times that of the star configuration)

The rated current input on the motor nameplate of P0305 motor is 0.00-10000 Arms 0.00, which directly affects the overcurrent protection threshold (p2100). Setting the wrong value may cause protection to trigger incorrectly or the motor to burn out

P0307 motor rated power input: The rated power on the motor nameplate is 0.00-100000 kW. The IEC standard unit is kW, and the NEMA standard unit is hp (when P0100=1)

P0310 motor rated frequency input: The rated frequency on the motor nameplate is 0.00-650.00 Hz. The default is 50Hz (IEC)/60Hz (NEMA), which affects the speed calculation (n=60f/p, p is the number of pole pairs)

The rated speed input on the nameplate of the P0311 motor ranges from 0.0 to 210000 rpm. 0.0 is used as the reference value for speed closed-loop control and, together with P0310, determines the number of motor poles (r0313)

P0340 automatically calculates parameters based on nameplate data to automatically calculate motor equivalent circuit parameters and control parameters 0-50 1=complete calculation, 2=motor parameter calculation, 3=closed-loop control parameter calculation, 4=controller parameter calculation, 5=threshold calculation

3. Control mode and speed parameters (p1000-p1999)

Parameter Number Parameter Name Core Function Value Range Default Values Key Explanation

P1000 frequency setting source selection frequency converter output frequency control mode 0-10 2 0=none, 1=terminal, 2=analog, 5=communication, 7=PID, 10=process controller

P1080 Minimum output frequency limit: The minimum output frequency of the frequency converter is 0.00-600.00 Hz to prevent overload during low-speed operation of the motor (such as pump loads to avoid idling)

P1082 Maximum output frequency limit: The maximum output frequency of the frequency converter should not exceed 1.2 times the rated frequency of the motor (p0310), from 0.00-600.00 Hz to 50.00/60.00 Hz, to avoid motor overspeed damage

P1120 Acceleration time from 0 to maximum frequency rise time 0.01-6500.0 s 10.0 The greater the load inertia, the longer the acceleration time needs to be to prevent overcurrent tripping

The descent time from maximum frequency to 0 for p1121 deceleration time is 0.01-6500.0 s 10.0, which needs to be matched with the load braking demand. For large inertia loads, the deceleration time needs to be extended or braking resistors need to be configured

P1300 control mode selection: The core control algorithm of the frequency converter is 0-22. 20=V/f control, 20=vector control (without encoder), 21=vector control (with encoder), 22=torque control

P1900 motor recognition automatically identifies motor equivalent circuit parameters, optimizes control accuracy 0-3 20=disabled, 1=static recognition, 2=dynamic recognition (motor idling required), 3=precise recognition

4. Fault protection parameters (p2100-p2299)

Parameter Number Parameter Name Core Function Value Range Default Values Key Explanation

P2100 overcurrent protection threshold setting: The upper limit of overcurrent protection current is 1.0-2.0 times the rated current, and 1.5 times the rated current. If the threshold is exceeded, the frequency converter will immediately trip to avoid damage to the power module

P2175 overvoltage protection threshold setting DC bus overvoltage protection threshold 1.0-1.3 times rated voltage 1.15 times suitable for voltage fluctuation scenarios in the power grid. If the threshold is too high, it may cause capacitor damage

P2176 undervoltage protection threshold setting DC bus undervoltage protection threshold 0.7-0.9 times rated voltage 0.85 times lower than the threshold, the frequency converter will operate at reduced capacity or trip to prevent insufficient motor torque

P2200 motor overheat protection enable/disable motor overheat protection function 0=disable, 1=enable 1 Based on motor temperature model (p0612) or temperature sensor signal, rated or tripped when overheated

P2260 torque limit motor output torque 0.0-200.0% 150.0% to prevent motor damage caused by load overload, which needs to be adjusted according to the rated torque of the load

5. Communication parameters (p2000-p2099)

Parameter Number Parameter Name Core Function Value Range Default Values Key Explanation

P2010 communication address (PROFIBUS/Modbus) setting: The address 1-126 of the frequency converter in the communication network should be consistent with the configuration of the upper computer (PLC/HMI) to avoid address conflicts

P2023 Communication Baud Rate (Modbus) Set the transmission rate of Modbus communication to 9600/19200/38400/115200 bps. The higher the baud rate, the faster the transmission speed, but it is limited by the communication distance (such as 115200bps, recommended distance<10m)

P2080 PROFIdrive status word mapping configuration for PROFIBUS/PROFINET status word signal source 0-65535 0 defines the operating status signals (such as ready, fault, running) fed back by the frequency converter to the PLC

P2081 PROFIdrive control word mapping configuration PROFIBUS/PROFINET control word signal source 0-65535 0 defines the control commands sent by PLC to the frequency converter (such as start stop, frequency setting, fault reset)

6. Input/Output (I/O) Parameters (p0700-p0799)

Parameter Number Parameter Name Core Function Value Range Default Values Key Explanation

P0700 Definition of Digital Input Function Allocation: Functions of Digital Input Terminals (DI) 0-99 2 0=No Function, 1=ON/OFF 1, 2=ON/OFF 2 (Emergency Stop), 3=ON/OFF 3 (Quick Stop)

P0730 Digital Output Function Allocation (DO0) defines the function of the digital output terminal (DO0) from 0 to 99. 52.0 0=no function, 52.0=ready state, 52.3=fault state, 52.7=alarm state

P0756 Analog Input Type (AI0/AI1) Set the signal type of the analog input terminal to 0-8 4 0=0-10V voltage input, 2=0-20mA current input, 3=4-20mA current input, 4=-10V~+10V bipolar voltage

P0771 Analog Output Function Allocation (AO0) defines the signal source 0-99 of the analog output terminal (AO0). 21.0 0 0=no function, 21.0=output frequency, 27.0=output current, 28.0=output voltage

(3) Read only parameters and status monitoring (r series)

The manual provides a detailed list of R-series read-only parameters for real-time monitoring of equipment operation status. The core parameters are as follows:

R0002: Driver operating status (e.g. 0=everything is normal, 10=need to activate set value, 35=need initial debugging);

R0021: Actual speed (smoothed), in rpm, reflecting the real-time speed of the motor;

R0025: Output voltage (smoothed), in Vrms, monitor the output voltage of the frequency converter;

R0027: Output current (smoothed), in Arms, to determine if the motor is overloaded;

R0031: Actual torque (smoothed), in Nm, reflecting the magnitude of the load torque;

R0052: Status word 1, displaying device ready, running, fault and other statuses through bit fields (such as bit0=ready, bit3=fault);

R0207: Rated current of power unit, reflecting the rated capacity of the inverter hardware;

R2135: Fault/alarm status word, records current or historical fault codes.

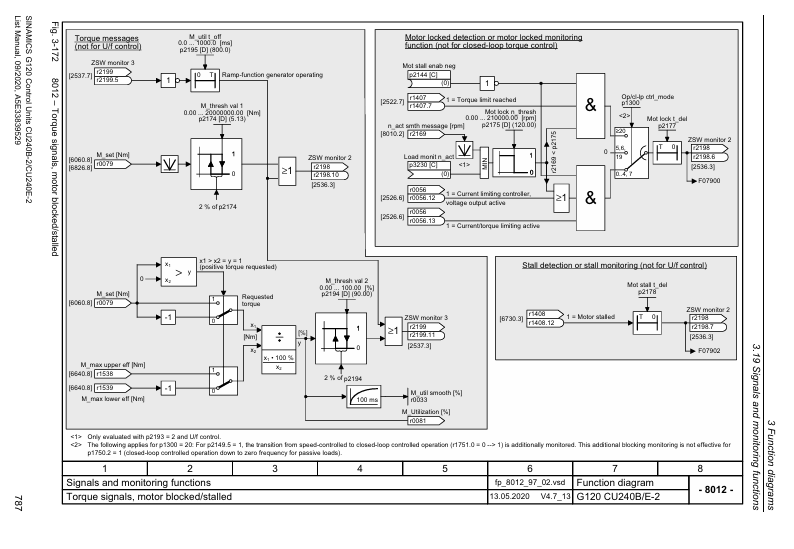

(4) Functional diagrams and logical associations

Chapter 3 of the manual provides detailed 590 page functional diagrams, covering:

Input/output terminal wiring logic (such as signal flow direction of DI/DO/AI/AO);

PROFIdrive communication protocol interaction logic (PROFIBUS/PROFINET data frame structure);

Control mode logic (such as speed closed-loop and torque closed-loop processes of vector control);

Fault protection logic (such as detection and tripping processes for overcurrent and overvoltage);

BICO parameter interconnection logic (such as the signal correlation between BI parameters and BO parameters).

Functional diagrams use standardized symbols to label parameter numbers and signal flow directions, helping technicians understand the underlying logic of parameter configuration. For example, the "speed control closed-loop" diagram clarifies the complete process of comparing r0021 (actual speed) and p1070 (speed set value), PID regulation, and output drive.

(5) Troubleshooting and Alarm Handling (Chapter 4)

Fault/alarm classification

Faults: The equipment cannot operate normally and needs to be manually reset after troubleshooting (such as F30002=DC bus overvoltage);

Alarm: The device can still operate but there are abnormalities that need attention (such as A07012=motor overheating warning).

Troubleshooting process

Step 1: Read the fault code through r2135 or the operation panel;

Step 2: Search the manual for the corresponding cause of the fault code (such as F30005=power unit I2t overload);

Step 3: Check according to the manual recommendations (such as checking if the load is overloaded and if the heat dissipation is good);

Step 4: Modify the corresponding parameters (such as adjusting the p2260 torque limit) or reset after fixing hardware faults.

Common faults and troubleshooting examples

F30002 (DC bus overvoltage): The reason may be that the grid voltage is too high and the deceleration time is too short; The processing method is to adjust the overvoltage threshold of p2175, extend the deceleration time of p1121, and configure the braking resistor;

F30005 (power unit I2t overload): The reason may be continuous overload of the load or a malfunction of the cooling fan; The processing method is to reduce the load, check the fan, and adjust the p0290 overload response strategy;

F07011 (motor overheating): The possible reasons may be excessive motor load or temperature sensor malfunction; The processing method is to reduce the rated operation, check the sensor, and adjust the P0605 overheating threshold.

Example of Key Application Scenario Parameter Configuration

Scenario 1: Pump/Fan Load (Standard Drive Control, p0096=1)

Basic configuration: p0010=1 (quick debugging) → p0300=1 (induction motor) → Input p0304/p0305/p0307/p0310 (motor nameplate data);

Control mode: p1000=2 (analog frequency source) → p1300=0 (V/f control);

Protection configuration: p2200=1 (motor overheating protection) → p2260=110% (torque limit);

Operating parameters: p1080=1.0Hz (minimum frequency anti slip) → p1120=30s (extended acceleration time waterproof hammer) → p1121=30s (extended deceleration time);

Confirm save: p3900=1 (complete quick debugging) → Parameters automatically take effect.

Scenario 2: Machine tool spindle load (dynamic drive control, p0096=2)

Basic configuration: p0010=1 → p0300=1 → Input motor nameplate data → p1900=2 (dynamic motor recognition);

Control mode: p1000=5 (communication frequency source) → p1300=20 (vector control without encoder);

Dynamic parameters: p1400=3.0 (PID proportional coefficient) → p1401=0.1 (PID integration time) → optimized dynamic response;

Protection configuration: p2100=1.8 (overcurrent threshold) → p2260=150% (torque limit) → p2175=1.2 (overvoltage threshold);

Communication configuration: p2010=5 (communication address) → p2080=1 (status word mapping) → p2081=1 (control word mapping);

Confirm save: p3900=2 → Restart the frequency converter to take effect.

Precautions and Risk Warning for Use

Before parameter configuration:

Confirm the control unit model and firmware version (r0018) to ensure parameter compatibility;

Disconnect the motor load or ensure that the load is in a safe state to avoid accidental operation of the equipment during debugging;

Backup the original parameters (p0971=1) for easy recovery in case of configuration errors.

In parameter configuration:

Strictly input the parameters p0300-p0311 according to the motor nameplate, incorrect settings may cause the motor to burn out;

Parameters related to safety functions (such as p0930 safety integration parameters) need to be configured by authorized personnel, and failure to comply with safety standards may result in personal injury;

The communication parameters must be consistent with the upper computer, otherwise a communication connection cannot be established.

After parameter configuration:

Conduct no-load testing (no-load operation), monitor parameters such as r0021/r0027/r0031, and confirm that the equipment is running normally;

Gradually load the load, observe whether the protection function is triggered, and verify the rationality of the parameters;

Record key parameters (such as motor data, communication address) for easy maintenance in the future.

Common risk avoidance:

Avoid modifying the rated parameters of the motor (p0304, etc.) during operation, which may cause instantaneous overload tripping;

Do not set p0290 (overload response) to 1 (trip directly without derating) unless there is no possibility of overload on the load;

Incorrect setting of analog input type (voltage/current) (p0756) can result in abnormal frequency setting.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923