K-WANG

SINAMICS SIRIUS series switchgear

SINAMICS SIRIUS series switchgear

Contactor Relay

Contactor relay is a key component for achieving "signal amplification and circuit switching" in industrial control. The document focuses on the 3RH2 and 3TH4 series, which complement each other in positioning and adapt to different scene requirements.

3RH2 series (size S00, compact)

(1) Product positioning and core features

Specially designed for compact control cabinets, with a size of only S00 (45mm wide), supporting 4-pole, 8-pole, and 4-pole latch types, it is the "basic contactor relay" of Siemens SIRIUS series, with core advantages including:

Multiple terminal selection: screw terminals (traditional wiring) and spring terminals (push in, tool free quick wiring) are optional;

Climate adaptation: operating temperature -25~+60 ℃, storage temperature -55~+80 ℃, suitable for use in high/low temperature industrial environments (such as cold chain workshops and metallurgical plants);

Safety compliance: Compliant with the IEC 60529 finger protection standard, both the basic unit and auxiliary switch have "forced guide contacts" (Appendix L of IEC 60947-5-1), which can be used for safety related applications (such as emergency stop circuits).

(2) Detailed product classification and model analysis

According to their functions and application scenarios, the 3RH2 series can be divided into four categories, with model codes following a fixed logic ("3RH2 @ @ - @ @ @ @ 0- @ @ @ @"). The meanings and examples of each field are as follows:

Product type Pole number Terminal type Coil voltage Model example Key characteristics Corresponding page numbers

Standard contactor relay 4-pole screw terminal 24V AC (50/60Hz) 3RH2140-1AB00 basic model, 4NO contact, terminal identification in accordance with EN 50011 5/12, 5/13

Standard contactor relay 8-pole spring terminal 230V AC (50/60Hz) 3RH2244-2AP00 8-pole (4NO+4NC) with permanently installed auxiliary switches 5/12, 5/13

Lock type contactor relay 4-pole screw terminal 24V DC 3RH2440-1BB40 requires external signal unlocking, suitable for "hold type circuit" (such as gate control) 5/12, 5/13

Coupling contactor relay (PLC compatible) 4-pole screw terminal 24V DC 3RH2140-1HB40 low power consumption (2.8W), wide coil working range (0.7~1.25 × Us), compatible with PLC solid-state output 5/14, 5/15

Railway application type contactor relay 4-pole screw terminal wide voltage coil 3RH2122-2K.40 coil voltage range extension, anti vibration (AC operation 11.4g/5ms) 4/64

(3) Key technical parameters (detailed explanation by dimension)

Technical parameters are the core basis for selection, and the document specifies the electrical, mechanical, and environmental performance of the 3RH2 series through tables and charts. The core data is as follows:

Size and Installation:

Component type Terminal type Width x Height x Depth (mm) Installation method

Basic unit screw terminal 45 × 58 × 73 fixed with screws/TH 35 rail clamp

Basic unit spring terminal 45 × 70 × 73 fixed with screws/TH 35 rail clamp

Basic unit+front auxiliary switch screw terminal 45 × 58 × 117 TH 35 rail card installation

Basic unit+functional module spring terminal 45 × 70 × 147 TH 35 rail card installation

Electrical performance:

Insulation voltage (Ui, pollution level 3): 690V, suitable for medium and high voltage industrial circuits;

Surge withstand voltage (Uimp): 6kV, strong resistance to grid surges;

Coil power consumption (cold state, 1.0 × Us):

AC 50Hz: Close at 37VA/power factor 0.8, maintain at 5.7VA/power factor 0.25;

AC 60Hz: closed 33VA/power factor 0.75, maintained 4.4VA/power factor 0.25;

DC: closed=hold, 4.0W (low power consumption suitable for battery powered scenarios);

Contact reliability: Contact stability at 17V/1mA (IEC 60947-5-4), fault frequency<10 ⁻⁸ (<1 fault per 100 million operations).

Lifespan and Durability:

Component type Mechanical life (10000 cycles) Electrical life (AC-15/230V, 10000 cycles) Remarks

Basic unit 3000 100 without auxiliary accessories, randomly switched (asynchronous phase)

Basic unit+auxiliary switch 1000 50 Auxiliary switch is front mounted, 4-pole maximum expansion

Solid state compatible auxiliary switch 500 30 compatible with solid-state circuits, without forced guiding contacts

(4) Accessory System and Application Expansion

The 3RH2 series supports a variety of accessories, which can achieve functional upgrades and convenient maintenance. The core accessories are as follows:

Accessory type, model, example, function description, installation method, corresponding page number

Auxiliary switch 3RH2911-. NF. 1-pole/2-pole, front/side mounted, expansion contact quantity (maximum 4-pole) snap fit installation 3/89, 3/99

Functional modules 3RA281., 3RA283. Direct start, star delta start module, integrated control logic front mounted 3/107

Surge suppressor 3RT2916-4MA10 RC component/varistor/diode, suppression coil disconnect surge front mounted, with LED indication 3/104, 3/105

Additional load module 3RT2916 increases allowable residual current (compatible with high residual current PLC output) Front mounted 3/121

Anti misoperation cover plate 3RT2916-4MA10 sealed terminal, preventing accidental contact or tampering with snap on cover 3/119

(5) Selection and ordering precautions

Model coding logic: It is necessary to clarify "number of poles → contact type (NO/NC) → terminal type → coil voltage → special version", for example, in "3RH2122-1AB00", "22" represents 2NO+2NC, "1" represents screw terminal, and "AB00" represents 24V AC coil;

Minimum order unit (PU): 1 unit (single unit), discounts are available for partial bulk orders (please consult Siemens sales);

Special requirements: Railway application type (wide voltage coil) and latch type require separate confirmation of delivery time, non-standard voltage (such as 48V DC) can be customized according to the "3/75 page" requirements.

2. 3TH4 series (8-pole/10 pole, multi circuit type)

(1) Product positioning and core differences

Unlike the "compact" positioning of the 3RH2 series, the 3TH4 series focuses on multi pole numbers and high reliability, designed specifically for "multi loop centralized control" scenarios (such as complex motor control and machine tool hydraulic systems). The core differences are reflected in:

More poles: Only 8 poles (3TH42) and 10 poles (3TH43), supporting more independent circuit switching;

More stable structure: greater depth (AC type 97mm, DC type 130mm), stronger impact resistance (AC operation 12g/5ms);

Single terminal type: only screw terminals (M3.5), suitable for connecting large cross-sectional wires (up to 4mm ²);

Narrow environmental adaptability: operating temperature -25~+55 ℃ (5 ℃ lower than 3RH2), more suitable for industrial environments at room temperature.

(2) Product classification and key parameters

Product classification: Divided by pole number into 3TH42 (8 poles) and 3TH43 (10 poles), both support AC/DC coils. The model examples are as follows:

Series pole control voltage terminal type model example corresponding page number

3TH42 8-pole 230V AC (50Hz) screw terminal 3TH4280-0AP0 5/20

3TH42 8-pole 24V DC screw terminal 3TH4280-0BB4 5/20

3TH43 10 pole 230V AC (50Hz) screw terminal 3TH4310-0AP0 5/21

3TH43 10 pole 24V DC screw terminal 3TH4310-0BB4 5/21

Core technical parameters:

Insulation voltage (Ui): 690V, impulse withstand voltage (Uimp): 8kV (2kV higher than 3RH2);

Coil power consumption (AC 50Hz, cold state): closed 68VA/power factor 0.82, maintaining 10VA/power factor 0.29;

Contact current capacity (AC-15): 10A at 230V, 6A at 400V, 4A at 500V, 2A at 690V;

Mechanical lifespan: 30 million cycles (basic unit), electrical lifespan (AC-15/230V): 3.6 million cycles (3 times higher than 3RH2).

(3) Accessories and Special Features

Surge Suppressor: 3TX7402 series, including diodes (24~250V DC, 3TX7402-3A), varistors (24~600V AC, 3TX7402-3G), RC components (24~600V AC, 3TX7402-3R), directly installed on coil terminals to suppress disconnection surges;

Delay device: 3TX4180-0A (ON delay, 0.1~5s), suitable for circuits that require delayed start (such as fan soft start);

Railway application type: coil voltage range extension (0.85~1.1 × Us), model such as 3TH42. -0B., needs to be ordered according to the requirements on page 4/66.

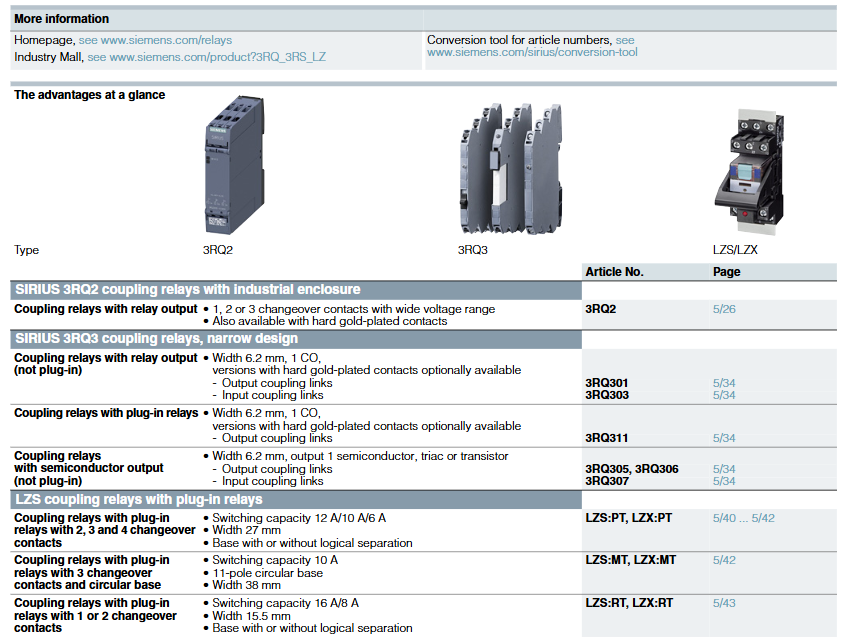

Coupling relay

Coupling relays mainly achieve electrical isolation and signal level matching between control circuits and load circuits. The document covers three major series: 3RQ2, 3RQ3, and LZS/LZX, corresponding to "industrial shell type, narrow design type, and plug-in customized type", meeting different installation spaces and customization requirements.

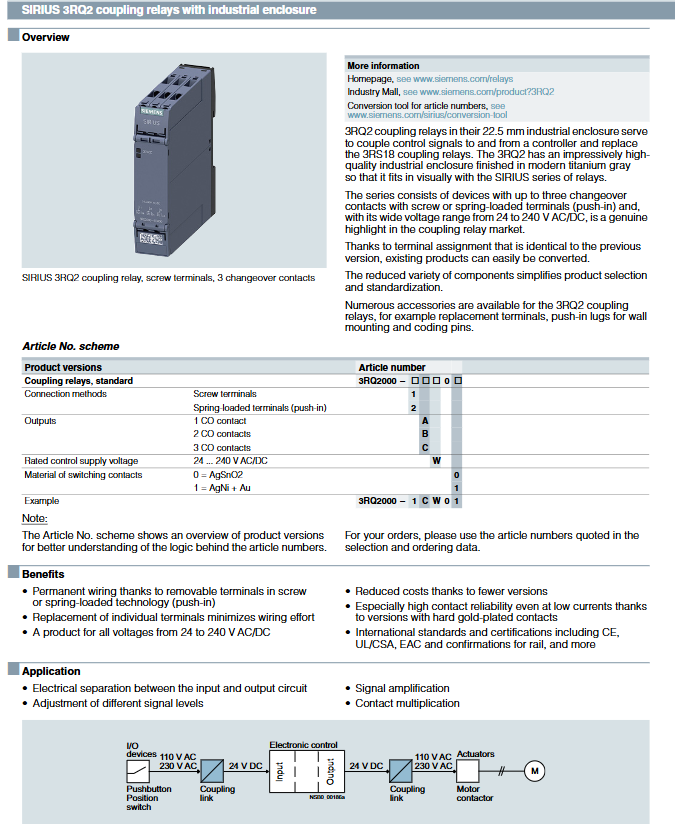

3RQ2 series (industrial shell type, 22.5mm)

(1) Product positioning and core advantages

Replacing the traditional 3RS18 series, designed specifically for industrial grade signal coupling, with a 22.5mm wide industrial casing (titanium gray) that is visually consistent with the SIRIUS series. The core advantages include:

Wide voltage compatibility: 24~240V AC/DC coils, no need to distinguish between AC and DC, reducing inventory types;

High contact reliability: Some models use "hard gold-plated contacts" (AgNi+Au), which provide stable contact in low current (≥ 1mA) and low voltage (≥ 17V) scenarios;

Easy to maintain design: detachable terminals (screw/spring type), no need to disconnect wires to replace terminals; TOP wiring (front wire entry) increases wiring efficiency by 30%.

(2) Product Classification and Technical Parameters

Product classification: Divided by the number of contacts into 1 conversion (CO), 2 conversion, and 3 conversion. Model examples and parameters are as follows:

Number of contacts, terminal type, contact material, coil voltage range, model example, working temperature, insulation voltage, corresponding page number

1. Conversion screw terminal AgSnO2 24~240V AC/DC 3RQ2000-1AW00-40~+60 ℃ 300V 5/26

2 Conversion Spring Terminal AgSnO2 24~240V AC/DC 3RQ2000-2BW00-40~+60 ℃ 300V 5/26

3 conversion screw terminals AgNi+Au 24~240V AC/DC 3RQ2000-1CW01-40~+60 ℃ 300V 5/26

Electrical performance:

Load current (AC-15/250V): 3A;

Load current (DC-13/24V): 1A;

Mechanical lifespan: 10 million cycles, electrical lifespan (AC-15/230V): 100000 cycles;

Protection level: IP20 (front), preventing solid foreign objects from entering.

(3) Accessories and Selection

Core accessories:

Accessory type, model, example, function description, ordering unit, corresponding page number

Detachable terminal 3ZY1122-1BA00 2-pole, screw terminal, maximum 4mm ² wire 6 units 5/26

Hinge cover 3ZY1450-1AB00 titanium gray, no terminal identification, protective terminal 5 units 5/26

Code pin 3ZY1440-1AA00 mechanical code terminal to prevent accidental insertion of 12 units 5/26

Special screwdriver 3RA2908-1A 3.0 × 0.5mm, designed for dismantling spring type terminals with 1 unit 5/26

Selection precautions: It is necessary to clarify the "number of contacts → terminal type → contact material → coil voltage", for example, "3RQ2000-2CW01" represents "2 conversion contacts, spring terminals, hard gold-plated contacts, 24-240V AC/DC coils".

3RQ3 series (narrow design type, 6.2mm)

(1) Product positioning and core innovation

Specially designed for high-density control cabinets, with a width of only 6.2mm (1/4 of traditional coupling relays), it is a representative of Siemens' "miniaturized coupling relays", with core innovations including:

TOP wiring+spring type terminal: front wire entry, tool free wiring, suitable for batch installation (such as automated production line control cabinets);

Multiple output types: Relay output (non plug/unplug) and semiconductor output are optional, suitable for different switching frequency requirements;

Integrated protection function: reverse polarity protection, EMC arc suppression diode, reducing the use of external protection components.

(2) Product Classification and Technical Parameters

Product classification: Divided into 3 categories based on output type, the core differences and parameters are as follows:

Output Type Model Series Contact/Output Characteristics Coil Voltage Range Operating Temperature Insulation Voltage Corresponding Page Number

Relay output (non plug and play) 3RQ3018/3RQ3038 1 conversion contact, AgSnO2/hard gold-plated 24~230V AC/DC -25~+60 ℃ 300V 5/34

Relay output (plug-in type) 3RQ3118 1 conversion contact, can quickly replace relay 24~230V AC/DC -25~+60 ℃ 300V 5/34

Semiconductor output (non plug and play) 3RQ3050/3RQ3070 contactless, 1mA~5A current capacity 11~30V DC/110~230V AC/DC -25~+60 ℃ 300V 5/34

Key performance differences:

Relay output: with a mechanical lifespan of 10 million cycles, suitable for switching between medium and low frequencies (≤ 1000 cycles/hour);

Semiconductor output: No mechanical wear, suitable for high-frequency switching (≤ 10000 times/hour), no contact bounce and noise.

(3) Accessories and Application Scenarios

Core accessories:

Accessory type, model, example, function description, ordering unit, corresponding page number

Isolation board 3RQ3900-0A electrically isolates different voltage circuits to prevent crosstalk of 10 units 5/35

Connect comb 3RQ3901-0A (2-pole) to the same potential terminal, with a current capacity of 6A 10 units 5/35

Label 3RQ3902-0A (5 × 5mm) Terminal Identification, White Handwritten 2000 units 5/35

Replace relay module 3TX7014-7BM00 with 3RQ3118, AgSnO2 contacts 15 units 5/35

Typical application scenarios:

Relay output: signal coupling between PLC and contactor (such as motor start stop control);

Semiconductor output: sensor signal amplification (such as photoelectric switch → PLC input), high-frequency light control.

3. LZS/LZX series (plug-in customized type)

(1) Product positioning and core features

Specially designed for customized control requirements, supporting free combination of "relay module+base+accessories", with core features including:

Multi type coverage: PT (industrial type, 28mm wide), MT (circular base, 38mm wide), RT (printed type, 15.5mm wide), suitable for different installation scenarios;

High environmental adaptability: Operating temperature -40~+70 ℃, can be used in extreme environments (such as outdoor control cabinets, high-temperature ovens);

Easy to maintain: Plug in relays can be replaced without disconnecting wires, reducing maintenance time by 80%.

(2) Product Classification and Technical Parameters

Product classification: Divided into 3 categories by structure, with the following core parameters:

Type Width (mm) Contact Quantity Terminal Type Coil Voltage Range Operating Temperature Insulation Voltage Corresponding Page Number

PT type (industrial) 28 2/3/4 conversion screw/spring terminal 24~230V AC/DC -40~+70 ℃ 250V 5/40~5/42

MT type (circular base) 38 3 conversion screw terminal 24~230V AC/DC -40~+60 ℃ 250V 5/42

RT type (printing) 15.5 1/2 conversion screw/spring terminal 24~230V AC/DC -40~+70 ℃ 250V 5/43

Special Features:

PT type: equipped with a test button (to forcibly switch relay status), LED module (24V DC version including freewheeling diode);

MT type: 11 pole circular base, suitable for special installation requirements (such as aerospace equipment);

RT type: 5mm pin spacing, suitable for printed circuit board (PCB) installation.

(3) Customized assembly and accessories

Customized assembly logic: Users can select in the order of "relay module → base → LED module → protective component", as shown in the following example:

Select relay module: PT type 3 conversion contact (LZX: PT370024, 24V DC);

Select base: Spring terminal base with logic separation (LZS: PT7874P);

Select LED module: green with freewheeling diode (LZS: PTMG0024);

Select protective component: RC component (LZS: PTMU0524, 24~60V AC).

Core accessories:

Accessory type, model, example, function description, adaptation type, corresponding page number

LED module (red) LZS: PTML0024 24V DC, with freewheeling diode, indicating relay status PT type 5/42

Fixed/pop-up bracket LZS: PT17021 auxiliary disassembly relay, suitable for dense installation of PT type 5/42

RC component LZS: PTMU0524 suppresses coil surge, 24~60V AC PT/MT/RT type 5/42

Connect comb LZS: PT170R6 (6-pole) to the same potential terminal, current capacity 10A PT type 5/42

General Technical Specifications and Safety Standards

At the end of the document, the universal connection methods, security features, and standard certifications for the entire series of products were added to ensure the compliance and security of technical applications.

1. Connection method (universal across the entire series)

Screw terminal: requires tool fastening, wire section 0.5~4mm ² (solid/multi strand with end sleeve), torque 0.8~1.2Nm (3RH2), 0.6~0.8Nm (3RQ2), suitable for large section wires and low vibration scenarios;

Spring terminal (push in):

Advantages: Tool free wiring (hard wire/soft wire with end sleeve), requires a 3.0 × 0.5mm screwdriver for wire removal, earthquake resistant (no risk of loosening), and does not require regular torque checks;

Wire cross-section: 0.5~4mm ² (solid), 0.5~2.5mm ² (multi strand with/without end sleeve);

Plug in terminal: Only supported by LZS series, suitable for scenarios that require frequent replacement of relays, with a wire cross-section of 0.75~1.5mm ².

2. Safety features and standard certification

Core standards:

IEC/EN 60947-1: General Standard for Low Voltage Switchgear;

IEC/EN 60947-4-1: Standard for contactors and motor starters;

IEC/EN 60947-5-1: Electrical standard for control circuits (including requirements for mandatory guide contacts);

IEC 60529: Standard for Degrees of Protection Provided by Enclosures (IP20/IP00/IP50).

Security features:

Finger protection: The front meets IP20 standards to prevent fingers from coming into contact with live parts;

Mandatory guiding contact: 3RH2 and 3TH4 series basic units are equipped to ensure that NO/NC contacts do not close simultaneously (essential for safe applications);

Short circuit protection: Suitable for G-type fuses (such as 3NA, 5SB) or C/B characteristic miniature circuit breakers, with a short-circuit current of 1kA (IEC 60947-5-1).

3. General requirements for installation and maintenance

Installation position: Vertical installation (base facing up), when installing 3TH4 series AC type on the side, a 5mm gap should be left (to prevent overheating);

Wiring specification: Separate the wiring of coils and contact circuits to avoid electromagnetic interference;

Maintenance cycle: Check the terminal fastening status (screw terminals) and contact wear every 6 months (measured by LED indicator or multimeter).

Summary and Core Values

This document serves as the authoritative technical manual for Siemens SIRIUS series switchgear, with core values reflected in:

Technical integrity: covering the entire series of contactor relays and coupling relays, with detailed parameters (including size, current, and lifespan), clear selection logic, and can directly guide engineering design;

Targeted application: classified according to "compact → multipole → industrial → narrow design → customized", suitable for different installation spaces and scene requirements;

Safety compliance: Clarify standard certification and safety features to help users avoid electrical safety risks;

Maintenance convenience: Detailed list of accessory system and maintenance specifications to reduce later operation and maintenance costs.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923