K-WANG

BENDER Greenlee 555C Electric Pipe Bending Machine

BENDER Greenlee 555C Electric Pipe Bending Machine

Product Overview

The Greenlee 555C electric pipe bending machine is a professional bending tool launched by Greenlee, a subsidiary of Textron. It is designed for various types of conduits and pipes with specifications ranging from 1/2 "to 2", and is mainly used in industrial electrical installation, building pipeline layout, and other scenarios. It can achieve precise and efficient bending operations. The product meets strict safety standards and is equipped with safety designs such as grounding protection and anti pinch point protection. It is paired with multiple sets of specialized bending accessories and detailed parameter tables to adapt to the bending needs of different pipes. The operation process is standardized to reduce operational difficulty.

Core parameters and physical characteristics

Category specific parameters

Dimensions: Height 1118mm (44 "), Width 724mm (28.5"), Depth 521mm (20.5 ")

Weight 118kg (260lb), including accessories, total weight approximately 159kg (350lb)

Power supply requirement: 120 VAC, 20 A GFCI protection circuit, NEMA L5-20 twist lock plug

Environmental adaptability working temperature -20 ℃~49 ℃ (-5 ℉~120 ℉), relative humidity 0~98%

Installation methods: vertical installation, horizontal installation (supports quick switching between two modes)

Adapt pipes and bending accessories

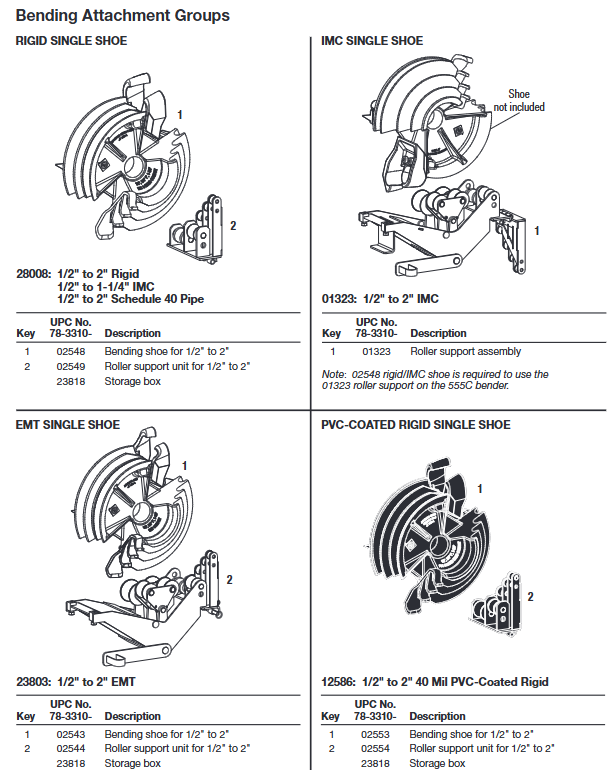

The product adapts to different types of pipes by replacing the bent boots and roller brackets. The core accessory set is as follows:

Attachment Group Type: Compatible with Pipe Core Components (including UPC Number Example)

Rigid single boot set (28008) 1/2 "-2" rigid conduit, 1/2 "-1-1/4" IMC, 1/2 "-2" 40 gauge steel pipe bending boot (78-3310-02548), roller bracket (78-3310-02549)

IMC single boot set (01323) 1/2 "-2" IMC roller bracket assembly (78-3310-01323), to be paired with 02548 rigid/IMC curved boots

EMT single boot set (23803) 1/2 "-2" EMT curved boot (78-3310-02543), roller bracket (78-3310-02544)

PVC coated rigid single boot set (12586) 1/2 "-2" 40 mil PVC coated rigid conduit bending boot (78-3310-02553), roller bracket (78-3310-02554)

Operation process and bending type

(1) Basic operation steps

Equipment settings: Select the corresponding bending shoe and roller bracket, install and fix them, adjust the horizontal screw to level them;

Pipe marking: Mark the bending point on the pipe according to the bending type (such as 90 ° short pipe, offset bending) and parameter table;

Loading positioning: Place the pipe into the groove of the bent boot, align the mark with the front edge of the boot hook, and ensure that the pipe path is unobstructed;

Bending operation: Press the BEND key to start bending, release when approaching the target angle, and short press to fine tune to the precise angle;

Unloading reset: Press the UNLOAD button, rotate the bending shoe in the opposite direction, twist the pipe to detach from the hook, reset to 0 °, and prepare for the next operation.

(2) Main bending types and parameters

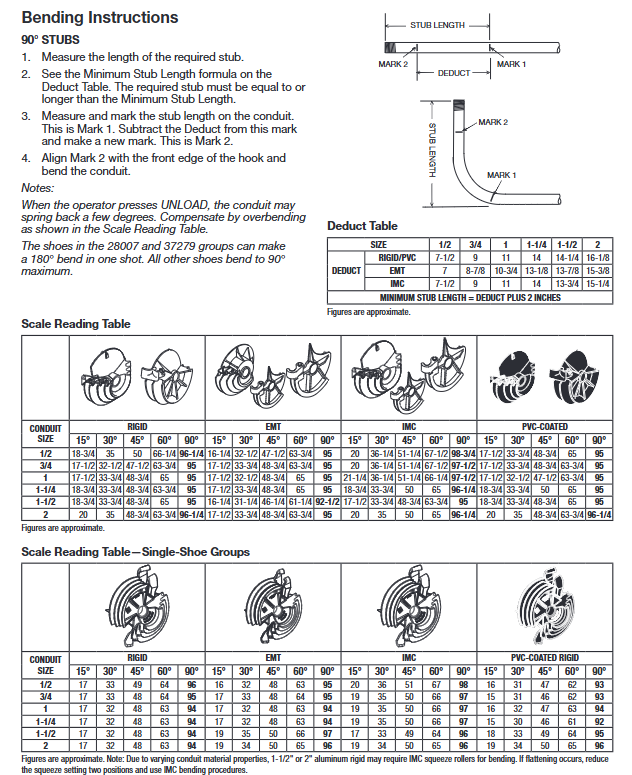

Bending type applicable scenario core parameter reference

90 ° short pipe vertical/horizontal pipeline turning minimum short pipe length=deduction value+2 inches, need to compensate for rebound angle

Deviation curve avoids obstacles with a deviation height of 2 "-22", center distance=deviation height x angle coefficient (15 ° coefficient 3.9, 30 ° coefficient 2.0, etc.)

Three curved saddle crossing small obstacles requires marking three bending points, referring to the L1, L2, and Z parameter tables

Four curved saddle crossing large obstacles including straight sections design, requiring marking of four bending points

U-shaped reciprocating pipeline layout angle of 90 °, refer to the Y value and L1 parameter table

Safety operation standards

Electrical safety: Only connect 120V, 20A GFCI protection circuits, do not modify power cords and plugs, and replace damaged cables in a timely manner;

Environmental safety: Do not use in flammable or humid environments, avoid exposure to rain, and wear eye protection equipment during operation;

Mechanical safety: Keep hands away from pinch points such as bent boots and rollers, do not remove protective covers, and do not use equipment as ladders;

Operation safety: Before replacing accessories, the power must be cut off. When handling, ensure that the handle is securely installed (with safety spring clips and elastic pins fixed), and multiple people cooperate to handle heavy components.

Maintenance and troubleshooting

(1) Daily maintenance

The gearbox is designed for sealing and does not require regular oil changes; If the lid is opened for repair, it needs to be cleaned with kerosene and filled with 26 fluid ounces of Mobil ® 634 synthetic oil;

Regularly check the chain tension and maintain appropriate tension by adjusting the eccentric cam and reducer position, with a torque standard of 47 Newton meters (35 foot pounds);

Keep the equipment clean, ensure that the label stickers are clear and readable, and promptly replace worn or damaged bent boots, rollers, and other components.

(2) Common fault handling

Possible causes and solutions for the fault phenomenon

The device is unable to operate due to power supply failure and the switch is not turned on. Check the power supply circuit and confirm that the switch is in the ON position

Excessive bending angle of 1-1/2 "or 2" EMT/IMC compression is too tight. Rotate the adjusting bolt counterclockwise to reduce the compression force

Insufficient bending angle, loose compression, differences in pipe characteristics. Rotate the adjusting bolt clockwise to increase the compression force, or compensate for excessive bending appropriately

Motor overload tripping, mismatched pipe specifications, incorrect installation of rollers/boots. Confirm that the pipe is compatible with the accessories and reinstall the bent boots and rollers

Accessories and Parts Support

The product provides a complete accessory system, covering bending accessories, repair parts, tools and consumables, etc. The core accessories include:

Mechanical accessories: Terminal cover, mounting clip (B91067903), screw terminal kit (B91067901);

Operating parts: Hanging switch (50398393), protractor, pointer kit (52065278);

Repair parts: motor (91869730), bearings, chain (# 60 87P), reducer (90523881).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923