K-WANG

BENDER ISOMETER ® Iso685 (W) - D/- S insulation monitoring equipment

BENDER ISOMETER ® Iso685 (W) - D/- S insulation monitoring equipment

Product Overview

ISOMETER ® Iso685 (W) - D/- S is a professional insulation monitoring equipment developed by Bender, a German company, specifically designed for IT systems (ungrounded AC/DC systems). Its core mission is to detect insulation faults in a timely manner by monitoring key parameters such as insulation resistance and DC offset voltage, avoiding risks such as electric shock and equipment damage. The product is divided into two variants: D-type (integrated graphic LC display and operation buttons) and S-type (no display/buttons, required to be used with FP200 (W) front-end panel), both supporting AC/DC/3 (N) AC system monitoring. With coupling equipment, the rated voltage monitoring range can be extended to 12 kV, meeting the needs of industrial scenarios with different voltage levels.

The product complies with international standards such as IEC 61557-8 and DIN EN 61557-8, and has high reliability and anti-interference ability. It is suitable for various scenarios such as industrial production lines, emergency power supply systems, and ship power, and is one of the core equipment to ensure the safe operation of the power system.

Core functions and features

(1) Monitoring and measurement functions

Insulation resistance monitoring

Measurement range: 0.1 k Ω~20 M Ω, alarm response value can be independently set within 1 k Ω~10 M Ω (ALARM1/ALARM2).

Preset response values: Factory default ALARM1=40 k Ω, ALARM2=10 k Ω, supports custom adjustment.

Measurement accuracy: ± 15% (minimum ± 1 k Ω), in accordance with the requirements of IEC 61557-8 standard.

Dual alarm mechanism: When the insulation resistance is lower than the corresponding response value, the relay action and LED indication are triggered, supporting fault memory (maintaining the alarm state until manual reset).

Multi parameter collaborative monitoring

DC offset voltage monitoring: A DC alarm threshold of 20 V~1 kV can be set to avoid the impact of DC components on the system.

System leakage capacitance monitoring: measurement range 0~1000 μ F, accuracy ± 10% (minimum ± 10 μ F), equipment automatically adapts to capacitance changes.

Connection monitoring: Real time monitoring of the connection status of the measurement line to avoid monitoring failure caused by line disconnection.

The multi measurement profile adaptation device provides 7 measurement profiles, which can be flexibly selected according to the system type to optimize measurement speed and accuracy:

Profile type applicable scenario key parameters

Power circuits - Conventional constant frequency systems with voltages ranging from 0 to 690 V (AC)/0 to 1000 V (DC) and capacitors ranging from 0 to 150 μ F

Control circuits: Low voltage sensitive control system measures voltage ± 10 V, voltage 0-230 V (AC/DC)

Generator monitoring rapid measurement, frequency 50-60 Hz, capacitance 0-5 μ F

High capacitance systems such as ships have a capacitance of 0~1000 μ F and a voltage of 0~690 V (AC)/0~1000 V (DC)

Variable frequency converter>10 Hz (inverter>10 Hz) 10~460 Hz Variable frequency system capacitance 0~20 μ F, voltage 0~690 V (AC)/0~1000 V (DC)

Frequency converter<10 Hz (inverter<10 Hz) 0.1~10 Hz Low frequency system capacitance 0~20 μ F, voltage 0~690 V (AC)/0~1000 V (DC)

Customer specific special needs scenarios are defaulted to be consistent with the power circuit profile and support Bender customization

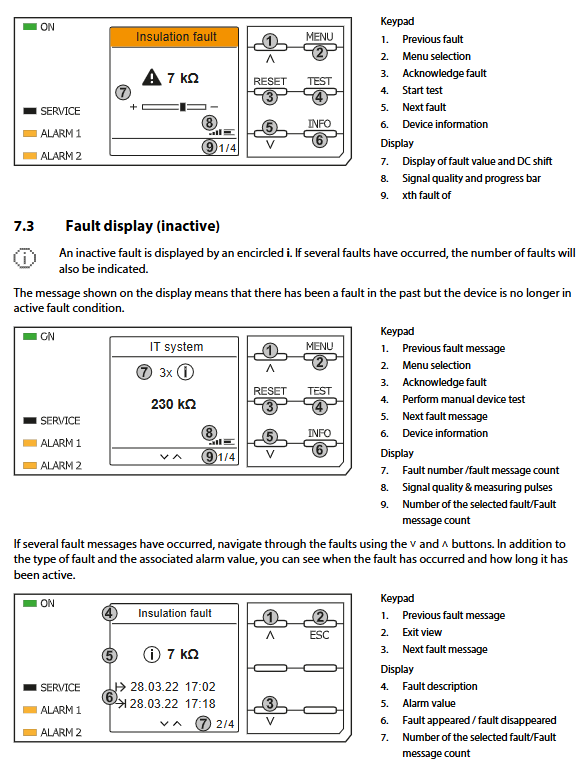

(2) Display and storage functions

Graphic display: equipped with a 127 × 127 pixel graphic LC display screen, real-time display of insulation resistance, alarm status, signal quality and other information, supporting multilingual switching (including English, German, etc.).

Historical memory: It can store 1023 alarm/fault information, each record containing date, time, fault type, and measurement value, and data will not be lost after power failure (continuous fault memory mode).

Trend analysis: The isoGraph function can graphically display the insulation resistance change trends for 1 hour, 1 day, 1 week, 1 month, and 1 year, facilitating fault tracing and system status prediction.

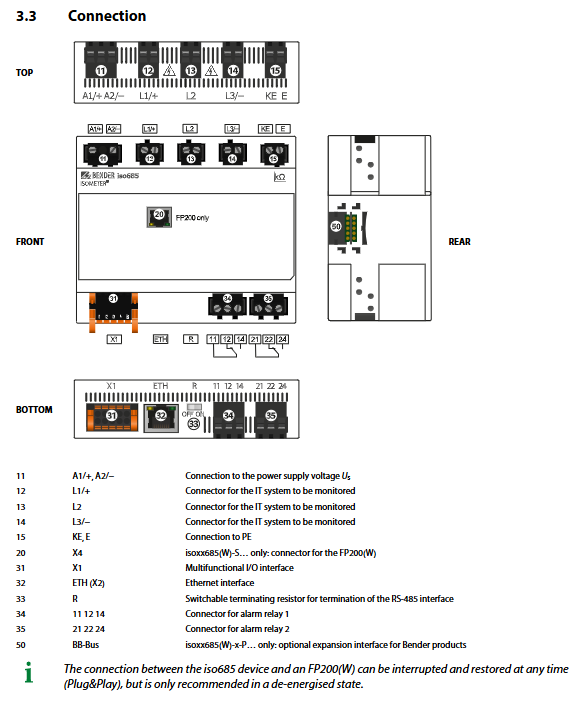

(3) Communication and Control Interface

The device supports multiple communication methods to achieve local and remote control:

Interface type communication protocol/functional key parameters

Ethernet (ETH) Modbus TCP, BCOM, Web Server 10/100 Mbit/s, supports DHCP/static IP, up to 5 TCP connections

RS-485 (X1 interface) BS bus, Modbus RTU, isoData baud rate 9.6 kBd~115 kBd, transmission distance ≤ 1200 m

X1 multifunctional I/O digital input (3 channels), digital output (2 channels), analog output (1 channel), analog output supports signals such as 0~20 mA/4~20 mA/0~10 V, etc

Relay output 2 conversion contacts (K1/K2) support N/C/N/O mode, AC-13 class 230 V/5 A, electrical life 10000 times

(4) Safety and operational assurance

Safety protection: Terminal protection level IP20 (external)/IP30 (internal components), shell flame retardant level UL94 V-0, with overvoltage and overcurrent protection.

Operation protection: Supports 4-digit password protection (0000~9999) to prevent unauthorized parameter modification; Continuous self-test function, automatically detects internal circuits, measurement circuits, and connection status after startup.

Convenient operation: Parameter setting, alarm reset, and self detection can be achieved through buttons such as MENU/TEST/RESET, and support remote parameter modification on web servers (with write permission enabled).

Model specifications and ordering information

(1) Core model parameters

Model Equipment Type Power Supply Voltage Protection Enhancement (Option W) Product Number

Iso685-D with display/button AC/DC 24~240 V No B91067010

Iso685W-D with display/button AC/DC 24~240 V (-40~+70 ℃, anti vibration) B91067010W

Iso685-S+FP200 no display+panel AC/DC 24~240 V No B91067210

Iso685W-S+FP200W without display+panel AC/DC 24~240 V is B91067210W

(2) Key components and coupling equipment

Basic accessories:

Mechanical accessories (terminal cover+mounting clip): B91067903

Screw Terminal Kit: B91067901

Push in terminal kit: B91067902

Front panel (FP200/FP200W): B91067904/B91067904W

Coupling equipment (extended voltage range):

Coupling device model applicable system voltage product number

AGH150W-4 3(N)AC 0~1150 V、DC 0~1760 V B98018006

AGH520S AC/3(N)AC 0~7200 V B913055

AGH204S-4 AC 0~1650 V (with rectifier 0~1300 V) B914013

AGH676S-4 AC 12 kV B913055

Key technical parameters

(1) Power supply and environmental parameters

Project Standard Version W Enhanced Version

Supply voltage range AC/DC 24~240 V (± 30%/± 15% tolerance) same as standard version

Power consumption ≤ 12 W (DC), ≤ 21 VA (AC 50/60 Hz) Same as standard version

Working temperature -25~+55 ℃ -40~+70 ℃ (UL application -40~+65 ℃)

Storage/transportation temperature -40~+70 ℃/-40~+85 ℃ Same as standard version

Protection level: internal IP30, terminal IP20, same standard version

Shell dimensions (width x height x depth) 108 mm x 93 mm x 110 mm as per standard version

Weight<390 g, same as standard version

(2) Measurement system parameters

Measurement parameter range accuracy

Insulation resistance 0.1 k Ω~20 M Ω± 15% (minimum ± 1 k Ω)

AC system voltage 0~690 V (RMS) ± 5% (minimum ± 5 V)

DC system voltage 0~1000 V ± 5% (minimum ± 5 V)

System frequency 0.1~460 Hz ± 1% (minimum ± 0.1 Hz)

Leakage capacitance 0~1000 μ F ± 10% (minimum ± 10 μ F)

DC offset voltage 20 V~1 kV-

Working principle and debugging process

(1) Basic workflow

After the device is connected to the power supply, it automatically starts self detection (15-20 seconds) to detect the internal circuit, measurement circuit, and grounding connection.

After passing the self-test, enter the normal monitoring mode and continuously collect parameters such as system insulation resistance and leakage capacitance.

When the insulation resistance is lower than the set response value, the response delay is activated (can be set to 0-300 seconds), and the corresponding alarm relay and LED indicator are triggered after the delay is over.

After troubleshooting, the parameters are restored to the release value (response value+25% hysteresis), the release delay is initiated, and the relay is reset after completion; When the fault memory is activated, the RESET button needs to be manually pressed to reset.

(2) Debugging process

Initial debugging: Connect the device → Connect the power supply → Run the debugging wizard (set language, date and time, system type, measurement profile, alarm response value) → Perform functional testing (simulate faults through grounding resistance).

Password configuration: Set a 4-digit password in the device menu, and verify it before modifying parameters.

Remote configuration: remotely read measurement values and modify parameters (with write permission enabled) through a web server (input device IP) or Modbus RTU protocol.

Typical application scenarios

Industrial power system: Monitor the insulation status of generators, frequency converters, and transformers to prevent equipment failures caused by insulation degradation.

Emergency power supply system: Insulation monitoring of backup power sources such as UPS and diesel generators to ensure the safety of power supply in emergency situations.

High capacitance scenario: For large leakage capacitance systems such as ships and rail transit, monitoring accuracy is optimized through "high capacitance" measurement profiles.

Low voltage control system: Insulation protection for industrial automation control circuits to prevent damage to sensitive components due to insulation faults.

Medium and high voltage expansion: Equipped with AGH series coupling equipment, monitor the insulation status of medium and high voltage IT systems such as 6 kV and 12 kV.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923