K-WANG

HIMA HIMax ® System Manual

HIMA HIMax ® System Manual

System core positioning and security level

Product type: Safety related control system, used for control tasks in the process and factory automation industry (such as process controllers, protection systems, burner systems, etc.).

Security certification:

Complies with IEC 61508 standard and supports SIL 3 level.

Compliant with EN 954-1 standard, reaching Category 4 level.

Compliant with ISO 13849-1 standard, performance level e.

Core design principle: Supports both "de energizing to trip" and "energizing to trip" principles, with some models certified for use in fire alarm systems (DIN EN 54-2, NFPA 72).

System hardware composition and structure

Key specifications and functions of component types

Base Plates models: X-BASE PLATE 10 01 with 10 slots, 01/02 with 15 slots, and 01 with 18 slots; Expand up to 15 expansion substrates (a total of 16); Blank modules need to be inserted to ensure ventilation

Up to 4 processor modules, supporting redundant configuration; Installation location restrictions (slots 3-6 of rack 0, slots 3-4 of rack 1); Core functions: Running user programs, self testing, secure communication management

The I/O module includes digital/analog input/output and counter input modules; Support channel redundancy and module redundancy (2-3 layers); Some modules support sequence of events (SOE) recording

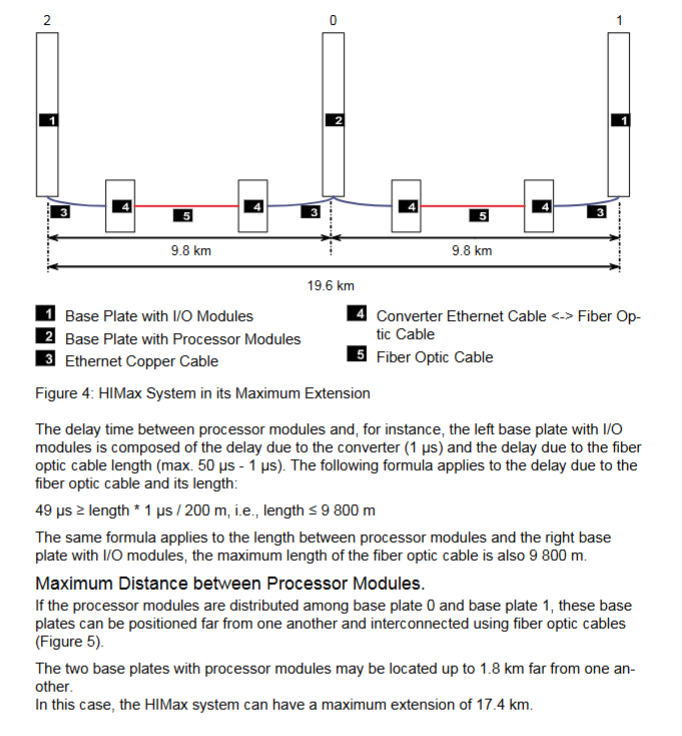

System bus dual redundancy (A/B bus), based on Ethernet technology; Copper cable up to 100m, fiber optic extension up to 19.6km; Cat. 5 (≤ 100Mbit/s) or Cat. 6 (1Gbit/s) cable required

Power supply 24VDC input (voltage range 19.2-30V); Support dual redundant power supply connection; Single substrate requires fuse protection of 63A or above

Software and Programming (Based on SILworX Tool)

Programming Fundamentals: Supports IEC 61131-3 standard functional blocks, can load up to 32 user programs, and supports multitasking scheduling (3 modes).

Variable management:

Types: local variables, global variables, input/output variables, etc.

Initial value: It is recommended to assign a secure initial value to physical input/communication variables. If not assigned, it defaults to 0.

System variables: pre-defined variables used to handle system properties such as temperature and power status.

Key functions:

Forcing function: supports global/local forcing, can set time limits, and requires authorized personnel to operate.

Event recording: Supports Boolean and scalar events, cache 5000 entries, and transmit them to third-party systems through X-OPC servers.

Loading methods: Download (interrupt running), Reload (uninterrupted running).

Redundant configuration (improves availability, not SIL level)

Key points for configuring redundant objects

1-4 redundant processor modules, with automatic synchronization configuration for newly added modules; Maintain safe operation of remaining modules during faults

I/O modules support module redundancy (2-3 modules of the same type) and channel redundancy; Configurable spare module to avoid false alarms

System bus dual bus (A/B), 2 system bus modules need to be inserted into each substrate; Prohibit cross connection

SafeEthernet communication supports redundant transmission paths; Standard protocols (Modbus, PROFIBUS) require user program management redundancy

Dual redundant power supplies are connected to terminals L1+/L1- and L2+/L2- to achieve voltage decoupling within the module

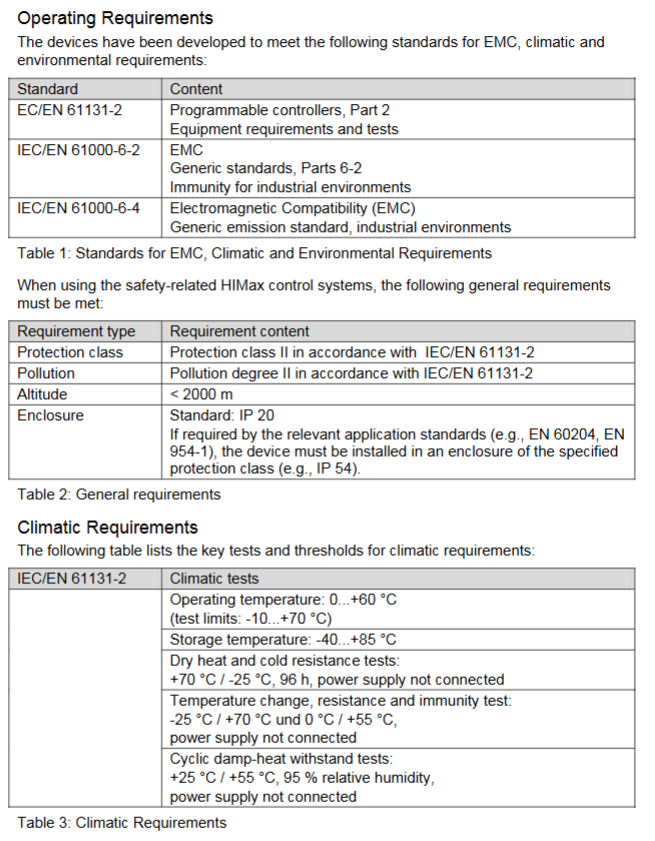

Operating environment and safety requirements

Environmental conditions:

Working temperature: 0-60 ℃ (testing limit -10-70 ℃), storage temperature -40-85 ℃.

Mechanical requirements: vibration tolerance (5-9Hz/3.5mm; 9-150Hz/1g), impact tolerance (15g/11ms).

Protection level: standard IP20, special scenarios require IP54+enclosure (compliant with EN 60204 and other standards).

Security protection:

ESD protection: Only authorized personnel with knowledge of ESD can modify the system or replace modules.

Prohibited use: public networks (such as the Internet) transmit security related data (without VPN/firewall); Exceeding the specified environment usage.

Emergency message: When the controller fails, the system automatically enters a safe state, and access to safety devices is prohibited in emergency situations.

Whole life cycle management

Installation: Must comply with EMC requirements (EN 61131-2, IEC 61000 series); Grounding requires the use of a 16/25mm ² grounding wire; The bending radius and strain relief of the cable must comply with the specifications.

Startup: Control cabinet startup (test voltage, ground fault) and PES startup (configure IP/SRS, set "responsible" system bus module); The rack ID needs to be allocated through the system bus module as a safety critical parameter.

maintain:

Regular requirement: Regular verification testing is required (refer to security manual HI 801 003); It is recommended to replace the fan regularly.

Fault handling: Only authorized by HIMA can be repaired; When the processor module fails, the redundant module takes over the task.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923