K-WANG

HIMA X-AO 16 01 HIMax ® Analog Output Module

HIMA X-AO 16 01 HIMax ® Analog Output Module

Core technical specifications

(1) Electrical and output parameters

Category specific specifications

Supply voltage 24 VDC (allowable range: -15%~+20%), SELV/PELV standard

Input current maximum 1.3A, minimum 0.6A (when all outputs are turned off), 80mA per channel

Output channel single channel connection: 16; Redundant connections: 8 (only odd numbered channels AO1, AO3... AO15)

Output range nominal: 4~20 mA; operating: 0~23 mA

Resolution and accuracy 16 bits (10000 digits in SILworX), LSB ≤ 2 µ A; accuracy at 25 ℃ ≤ ± 0.2% full scale, full temperature range ≤ ± 0.5% full scale

Load capacity: maximum resistance of 600 Ω, maximum inductance of 1mH, maximum capacitance of 100 µ F (parallel resistance load)

The response characteristic establishment time is 5ms, and the fault shutdown time is 16ms (in accordance with the principle of "power-off tripping")

(2) Environmental and physical parameters

Working temperature: 0~+60 ℃, storage temperature: -40~+85 ℃

Humidity: Maximum 95% relative humidity (without condensation)

Protection level: IP20

Dimensions (H × W × D): 310 × 29.2 × 230 mm, weight approximately 1.2kg

Altitude:<2000m, pollution level: Level II (IEC/EN 61131-2)

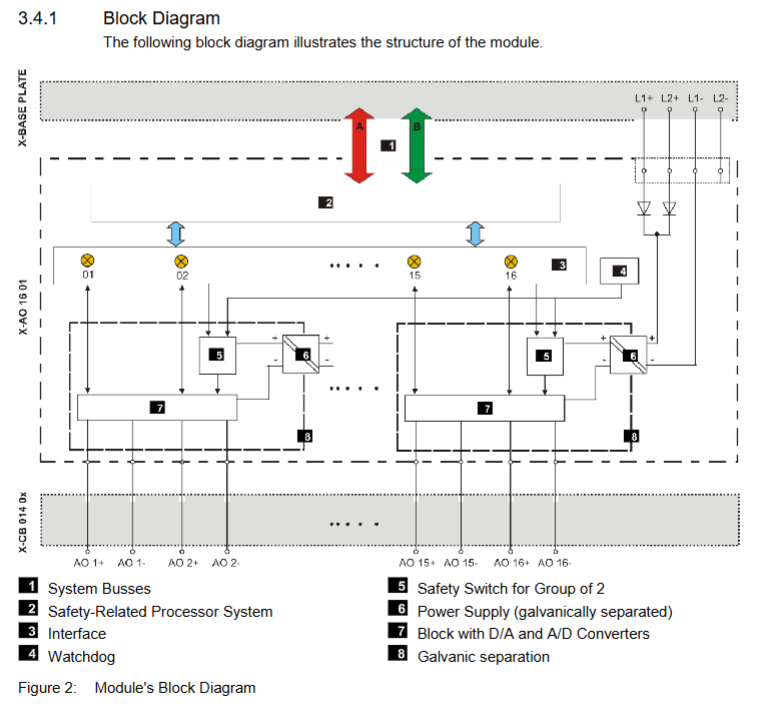

Hardware composition and connection

(1) Compatible connector board

Model, type, and purpose

X-CB 014 01 single channel, screw terminal single module screw terminal wiring

X-CB 014 02 redundant, screw terminal dual module redundant screw terminal wiring

X-CB 014 03 Single Channel, Cable Plug Single Module Cable Plug Wiring

X-CB 014 04 redundancy, cable plug dual module redundant cable plug wiring

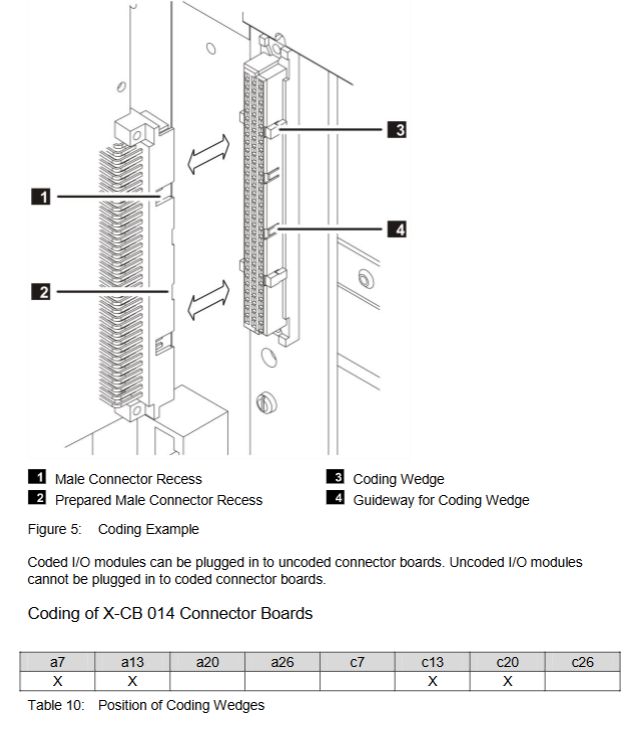

Mechanical coding: The connector board and module are protected against accidental insertion through wedge-shaped coding, and the coding position follows the X-CB 014 series specifications

(2) System cable

Model: X-CA 011 (LIYCY-TP 18 × 2 × 0.25 mm ²)

Length: standard 8m, 15m, 30m, minimum bending radius: fixed installation 5 x cable outer diameter, flexible application 10 x cable outer diameter

Characteristics: Flame retardant and self extinguishing (compliant with IEC 60332-1-2/-2-2), color coding follows DIN 47100

(3) Wiring method

Single channel wiring: Use X-CB 014 01/03 to directly connect the actuator

Redundant wiring (serial): using X-CB 014 02/04, dual modules installed adjacent to each other, sharing actuators

Closed loop control: AO output → actuator → AI input (such as X-AI 32 01) → processor module, forming a feedback loop

FTA connection: Through X-FTA 002 01/X-FTA 009 02, connect the module to the on-site terminal components via system cables

HART communication: The handheld device is connected in parallel at both ends of the actuator, and the residual error after compensating for communication current fluctuations is ≤ 2% of the full range

Configuration and Operation (Based on SILworX Tool)

(1) Core configuration items

Key parameter description for configuring labels

Module Noise Blanking is activated by default, and the processor module delays response to transient faults

Missing modules in the redundant group of Spare Modules are not considered as faults and are automatically shut down by default

I/O submodule AO16_01 Background Test Error: True=Test Fault, False=Normal

I/O submodule AO16_01 Restart on Error Force the faulty module to restart and self check, default shutdown

The default mapping value for Channels 4mA/20mA is 4.0/20.0, and unused channels should be kept as default

After activating Channels redundancy, it is added to the redundancy group and is turned off by default

Channels status (Channel OK): True=Channel normal, False=Channel fault (output set to 0)

(2) Diagnostic status code

Module Status: 32-bit WORD, such as 0x00000001=module fault, 0x00000010=L1+voltage fault

Submodule Status: For example, 0x00000040=module shutdown due to overcurrent, 0x00000010=temperature threshold 1 overtemperature

Channel diagnosis: supports open circuit detection (OC) and OC Monitoring Defect

Safety and maintenance requirements

(1) Security protection

ESD protection: Only authorized personnel with ESD knowledge are allowed to operate, and must wear anti-static wristbands. Unused modules must be stored in their original packaging

Fault response: In case of module failure, all outputs should be turned off within 16ms; When there is a channel failure, turn off the corresponding channel group (2 channels), and the Error LED will light up

Ex area use: Additional explosion-proof measures need to be taken to avoid sparks caused by plugging and unplugging loaded connectors

(2) Maintenance and disposal

Verification testing: to be conducted every 10 years, refer to the security manual HI 801 003 E

Operating system update: Use system downtime to load the latest version, modules need to be in STOP state

Repair authorization: Only HIMA company has the right to repair, unauthorized intervention will result in safety function failure and warranty failure

Transportation and discontinuation: Original packaging is required for transportation (to prevent ESD and mechanical damage); Discontinuation requires disassembly from the substrate and disposal according to environmental requirements

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

BENTLY NEVADA 3500/15 133292-01 Power Supply Module

-

ABB PM877 3BDH000777R1 Central_Unit Controller

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB