K-WANG

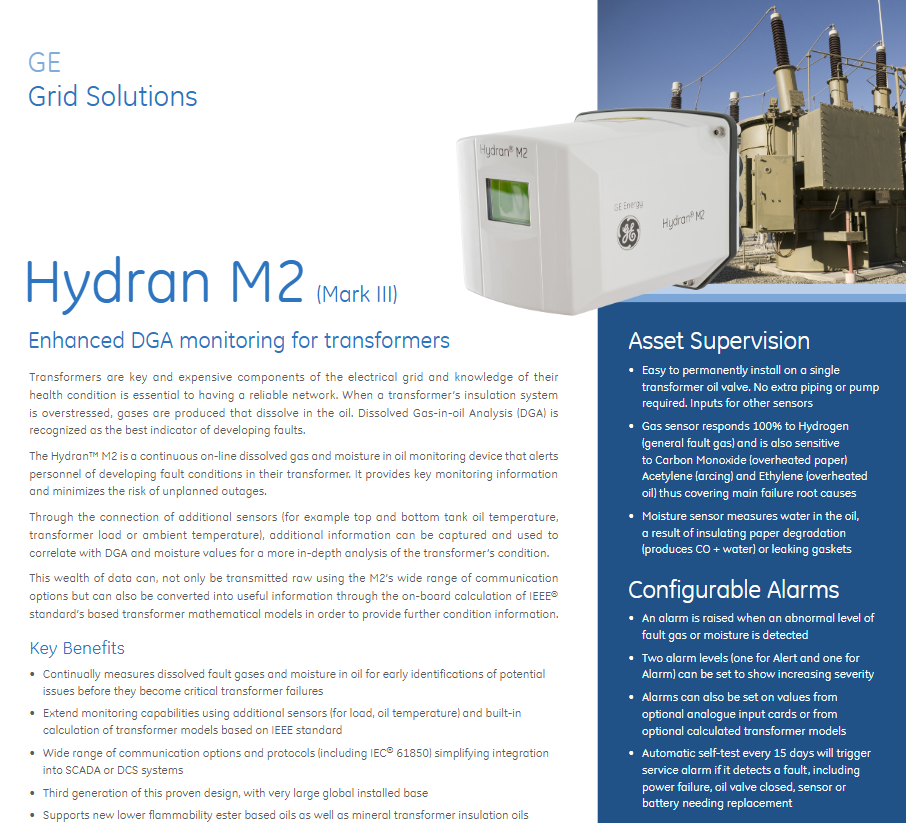

GE Grid Solutions Hydran M2 (Mark III) Transformer Oil Dissolved Gas and Moisture Monitoring Device

GE Grid Solutions Hydran M2 (Mark III) Transformer Oil Dissolved Gas and Moisture Monitoring Device

Core positioning and product value

Hydran M2 (Mark III) is GE's third-generation transformer condition monitoring equipment, based on Dissolved Gas Analysis (DGA) technology (an industry recognized core tool for transformer fault warning). By continuously monitoring the dissolved gas and moisture content generated by insulation system stress in the insulation oil, it achieves a full process management of "early fault identification risk assessment operation and maintenance decision support". Its core positioning is:

Guardian of key assets in the power grid: for transformers (high-value and high impact core equipment in the power system), to avoid unplanned shutdowns caused by insulation failures;

Multi dimensional state analysis platform: not only monitors the basic gas and moisture, but also can be connected to additional sensors (such as oil temperature and load current), combined with IEEE standard mathematical models, to output in-depth analysis results of transformer health status.

Core Product Value

Fault early warning: Continuously monitor the fault gases (such as hydrogen, acetylene, ethylene) and moisture, issue an alarm before the fault develops into serious damage, and avoid sudden shutdown;

Improved operation and maintenance efficiency: No need for regular manual sampling and testing, reducing on-site operation and maintenance workload, while supporting remote data transmission, achieving centralized asset management;

Wide compatibility: compatible with traditional mineral insulation oil and new low flammability ester insulation oil (natural/synthetic), covering transformers of different ages and types;

Reliability verification: The third-generation mature design has a large global installation base, has undergone long-term on-site verification, and complies with RoHS environmental standards.

Core functions and monitoring capabilities

(1) Basic monitoring function: gas and moisture monitoring

Hydran M2 achieves precise monitoring of key indicators in transformer insulation oil through dedicated sensors, covering the gas characteristics of the main types of transformer faults:

Monitoring indicators, sensor types, core monitoring targets, and fault associations

Dissolved Fault Gas Fuel Cell Type (Breathable Membrane Design) - Hydrogen (H ₂, 100% Sensitivity): A universal fault gas that can be generated by insulation oil/paper overheating and partial discharge;

-Carbon monoxide (CO, 15% sensitivity): insulation paper overheating;

-Acetylene (C ₂ H ₂, 8% sensitivity): Arc discharge (severe fault signal);

-Ethylene (C ₂ H ₄, 1.5% sensitivity): Overheating of insulation oil

Moisture in oil film capacitive type (immersion type) monitors the relative humidity (RH) in oil, reflecting the aging of insulation paper (moisture generation) or leakage of sealing gasket (external moisture intrusion). Excessive moisture will accelerate insulation degradation

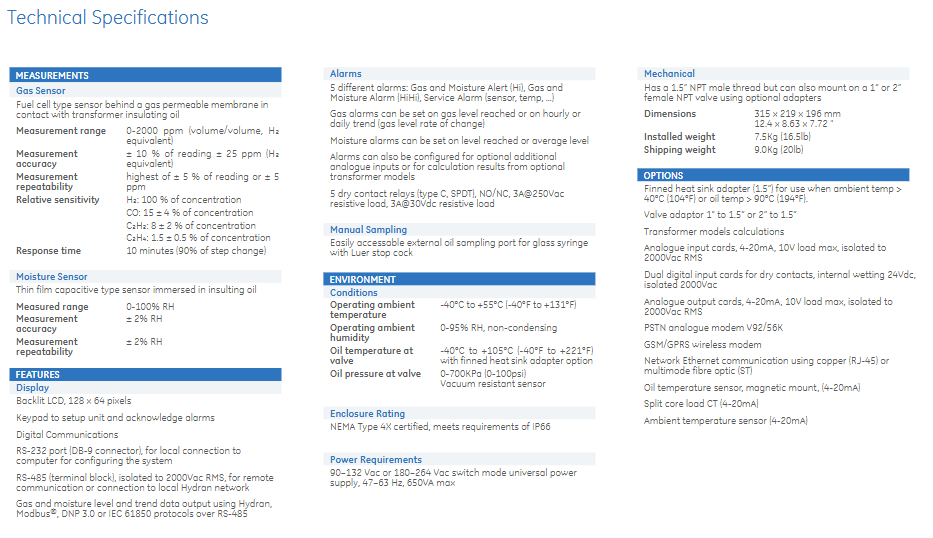

Key parameters for gas monitoring

Monitoring range 0-2000 ppm (volume ratio, calculated as H ₂ equivalent value)

Measurement accuracy ± 10% reading ± 25 ppm (H ₂ equivalent value)

Repeatability ± 5% reading or ± 5 ppm (whichever is greater)

Response time of 10 minutes (reaching 90% of the step change)

Key parameters for moisture monitoring

Measurement range 0-100% RH (relative humidity)

Measurement accuracy ± 2% RH

Repeatability ± 2% RH

(2) Expand monitoring and analysis capabilities

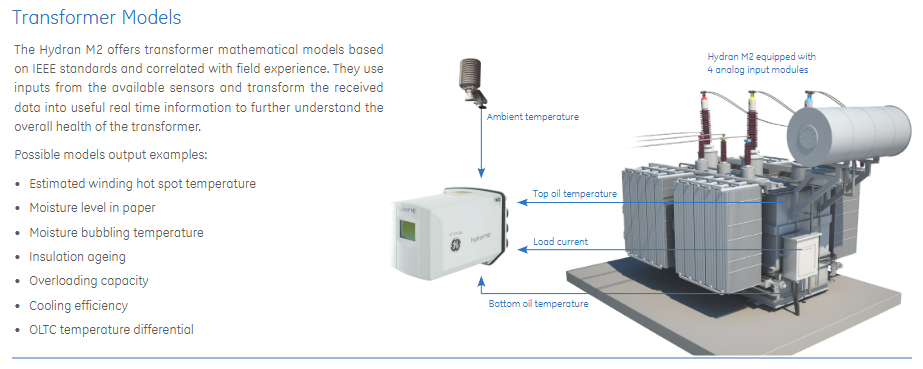

Multi sensor access: Supports external 4-channel analog input modules and can be connected to the following key parameter sensors to achieve linkage analysis of "gas moisture operating conditions":

Environmental temperature sensor;

Transformer top/bottom oil temperature sensor;

Load current sensor (split core CT, 4-20mA output).

IEEE standard mathematical model calculation: based on multi-dimensional data access, built-in transformer health status model that complies with IEEE standards, outputting intuitive operation and maintenance decision basis. The core model output includes:

Estimation of winding hotspot temperature (assessment of insulation thermal aging risk);

Moisture content in insulation paper (which better reflects the true aging state of insulation paper than moisture in oil);

Moisture bubbling temperature (warning of insulation breakdown risk caused by water analysis in low-temperature environments);

Insulation aging degree, overload capacity, cooling efficiency, temperature difference of on load tap changer (OLTC), etc.

(3) Alarm and self diagnostic functions

Multi level alarm configuration: supports flexible setting of alarm thresholds, covers different levels of fault severity, and avoids false alarms or missed alarms:

Gas alarm: can be triggered based on "absolute value of gas concentration" and "hourly/daily trend" (gas growth rate);

Moisture alarm: can be triggered based on "absolute value of moisture concentration" and "average moisture level";

Extended alarm: supports triggering alarms based on external sensor data (such as high oil temperature) and model calculation results (such as winding overheating);

Alarm level: divided into two levels: "Alert" and "Alarm", clearly distinguishing the priority of risks.

Automatic self diagnosis: Perform equipment self inspection every 15 days. If a fault is detected (such as power failure, oil valve closure, sensor failure, battery replacement), it will automatically trigger a "maintenance alarm" to ensure the reliability of the monitoring device itself.

(4) Data communication and integration capabilities

Hydran M2 supports multiple communication protocols and interfaces, and can be seamlessly integrated into existing power grid monitoring systems (SCADA/DCS) to achieve remote data transmission and centralized management

Communication interface:

Local interface: RS-232 (DB-9 connector, used for local computer configuration);

Remote interface: RS-485 (terminal block, 2000Vac RMS isolation, supports multi device networking);

Optional extensions: Ethernet (copper RJ-45/multimode fiber ST), GSM/GPRS wireless modem, PSTN analog modem (V92/56K).

Communication protocol: Supports Hydran private protocol Modbus ®、 DNP 3.0, IEC 61850 (standard communication protocol for power systems, adapted to smart grid architecture).

Data output: capable of transmitting raw monitoring data (gas concentration, moisture value), alarm status, model calculation results, and supporting integration with GE Perception ™ Software (GE dedicated data analysis platform) to achieve data trend analysis, historical comparison, and report generation.

Technical specifications and environmental adaptability

(1) Core technical parameters

Category specific parameters

Display and operation backlit LCD (128 × 64 pixels) with buttons (for device configuration and alarm confirmation)

Relay output 5-way dry contact relay (C-type SPDT), rated load: 3A@250Vac (obstructive) 3A@30Vdc (obstructive)

Power requirements for wide switching power supply: 90-132 Vac or 180-264 Vac, 47-63 Hz, maximum 650VA

Mechanical dimensions are 315 × 219 × 196 mm (12.4 × 8.63 × 7.72 inches)

Weight: Installation weight 7.5Kg (16.5lb), transportation weight 9.0Kg (20lb)

Installation interface with 1.5-inch NPT external thread, optional 1-inch/2-inch NPT internal thread adapter (suitable for different transformer oil valves)

(2) Environmental adaptability (ensuring harsh operating conditions)

Scope of adaptation to environmental conditions

Working environment temperature -40 ° C to+55 ° C (-40 ° F to+131 ° F)

Working environment humidity 0-95% RH (non condensing)

The oil temperature at the valve is -40 ° C to+105 ° C (-40 ° F to+221 ° F), and can be paired with a finned heat dissipation adapter for high temperature scenarios

Oil pressure at the valve: 0-700 kPa (0-100 psi), supports vacuum environment (vacuum tolerance sensor)

Protection level NEMA 4X (IP66), dustproof, splash proof, suitable for harsh outdoor/substation environments

Application scenarios and target users

Hydran M2 is mainly aimed at key scenarios in the power industry and industrial sector that rely on transformers. The core users and application values are as follows:

(1) Electricity utilities (grid companies)

Application scenario: Centralized monitoring of medium capacity transformers (such as distribution transformers, regional substation main transformers);

Core values:

Optimize asset replacement strategy: Based on equipment health status data, prioritize the replacement of high-risk transformers to avoid blind investment;

Reduce unplanned shutdowns: Early warning of faults, reduce the risk of power grid interruption, and ensure the reliability of residential and industrial electricity.

(2) Industrial factories (such as chemical, metallurgical, and manufacturing industries)

Application scenario: Factory owned substation transformer (to ensure power supply for production processes);

Core values:

Avoiding production interruptions: Transformer failures can cause production line shutdowns, and monitoring devices can reduce costly downtime caused by power failures;

Simplified operation and maintenance: No need for frequent manual sampling, reducing the workload of factory equipment management.

(3) Asset regulatory agencies

Application scenario: Remote supervision of multi site transformers by third-party asset operation and maintenance companies;

Core values:

Convenient installation: directly installed on the transformer oil valve, without the need for additional pipelines or pump bodies, reducing on-site renovation workload;

Centralized management: Multiple device data aggregation is achieved through communication networks to generate unified operation and maintenance reports.

Mark III version core improvements (compared to previous generation)

As a third-generation product, the Hydran M2 (Mark III) has undergone comprehensive upgrades in reliability, compatibility, and functional scalability

Hardware optimization: increased durability of sensors, redesigned electronic boards and power supplies to comply with RoHS environmental standards, while improving overall equipment reliability;

Oil compatibility expansion: Added support for low flammability ester insulating oils (natural/synthetic), covering new environmentally friendly transformers;

Software integration upgrade: compatible with GE Perception ™ Data analysis software that enables trend tracking, root cause analysis of faults, and automatic report generation;

Rich expansion modules: adding analog input/output cards, digital input cards, and wireless communication modules (GSM/GPRS) to meet the monitoring and integration needs of different scenarios.

Optional accessories (extended functions)

To meet the needs of different scenarios, Hydran M2 offers a variety of optional accessories to further enhance monitoring capabilities and environmental adaptability:

Accessory Name Core Purpose

Fin type heat dissipation adapter (1.5 inches) is used when the ambient temperature is greater than 40 ° C or the oil temperature is greater than 90 ° C to prevent equipment performance from being affected by high temperatures

Oil valve adapter (1 inch → 1.5 inches/2 inches → 1.5 inches) is suitable for different specifications of transformer oil valves, without the need to replace the original valve

Analog input/output card connected to 4-20mA signal sensor (such as oil temperature, load), outputting 4-20mA control signal, 2000Vac RMS isolated

Digital input card with dry contact signal (such as device status feedback), built-in 24Vdc wet contact power supply

Wireless/wired communication module GSM/GPRS wireless modem, Ethernet module (copper cable/fiber optic), to achieve remote data transmission

Specialized sensors include magnetic installation oil temperature sensor, split iron core load CT, and ambient temperature sensor (all with 4-20mA output)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923