K-WANG

MOOG Rugged Motion Controller

MOOG Rugged Motion Controller

Core positioning and functions of the product

Design objective: A high-performance motion controller designed specifically for harsh environments, meeting the requirements of high-speed control. It can be directly installed on equipment sites without the need for additional electronic control cabinets and is compatible with both electric and hydraulic motion systems.

Core competencies:

It has the same high computing performance as other Moog motion controllers and supports free programming through the powerful IEC 61131 development environment (Moog Axis Control Software, MACS).

Integrated PLC function can meet the multitasking requirements in embedded control scenarios, suitable for industrial control scenarios with high stability and real-time requirements.

Core advantages of the product

The core competitiveness of this controller lies in "environmental adaptability" and "functional flexibility", including:

High protection level: Adopting a special shell, the protection level reaches IP67, and it can work stably in humid and dusty environments.

Wide temperature range and resistance to harsh conditions: The working temperature range is extended to * * -40~+70 ° C (-40~+158 ° F) * *, with high resistance to vibration (30g vibration) and impact (50g impact), and can resist fluid pollution (such as brake fluid, hydraulic oil, diesel, etc.) and corrosion.

Flexible communication: Provides multiple types of bus interfaces to meet the communication needs of different industrial scenarios (such as real-time control, programming and debugging, sensor connection, etc.).

High computing performance: equipped with a professional processor, supporting complex motion control algorithms and multitasking processing.

Applicable application scenarios

Controllers are widely used in the following industrial fields due to their strong environmental adaptability and high performance:

Energy sector: Wind turbines

Metal processing: Presses and metal forming equipment

Heavy industry: Steel, Aluminum

Testing and Simulation: Test and Simulation Systems

Chemical Industry and Robotics: Chemical Industry, Robotics Technology

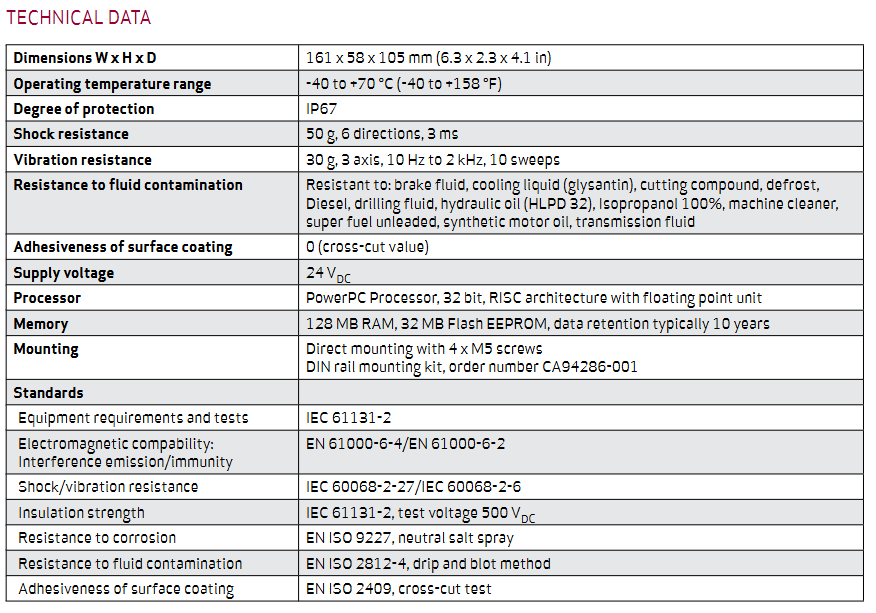

Key Technical Parameters (Specifications)

Category specific parameters

Dimensions (W × H × D) 161 × 58 × 105mm (6.3 × 2.3 × 4.1 inches)

Working temperature range -40~+70 ° C (-40~+158 ° F)

Protection level IP67

50g impact resistance, 6 directions, 3ms

Vibration resistance 30g, 3-axis, 10Hz~2kHz, 10 scans

Fluid pollution resistance can resist 12 common fluids including brake fluid, coolant, cutting fluid, diesel, hydraulic oil (HLPD 32), etc

Supply voltage 24V DC

32-bit PowerPC processor, RISC architecture, with floating-point arithmetic unit

Storage capacity: 128MB RAM, 32MB Flash EEPROM (data retention period usually 10 years)

Installation method: Install 4 M5 screws directly; DIN rail installation kit (order number CA94286-001)

Follow standard equipment requirements: IEC 61131-2; Electromagnetic compatibility: EN 61000-6-4/EN 61000-6-2; Corrosion resistance: EN ISO 9227, etc

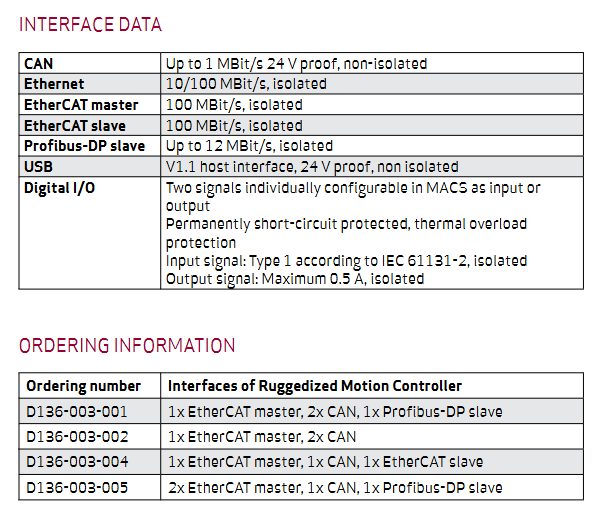

Interface Data

The controller provides a variety of interface types to meet different communication and control needs, with specific parameters as follows:

Specific specifications of interface type

CAN maximum 1MBit/s, 24V protection, non isolated

Ethernet 10/100MBit/s, isolation

EtherCAT main station 100MBit/s, isolated

EtherCAT slave 100MBit/s, isolated

Profibus DP slave up to 12MBit/s, isolated

USB 1.1 host interface, 24V protection, non isolated

Digital I/O 2-channel signal (configurable as input/output through MACS); Equipped with short-circuit protection and thermal overload protection; Input complies with IEC 61131-2 Type 1 (isolated), output maximum 0.5A (isolated)

Ordering Information

Different models correspond to different interface configurations, and users can choose according to the scenario, as follows:

Ordering No. Controller Interface Configuration

D136-003-001 1 1 x EtherCAT master station, 2 x CAN, 1 x Profibus DP slave station

D136-003-002 1 x EtherCAT master station, 2 x CAN

D136-003-004 1 x EtherCAT master station, 1 x CAN, 1 x EtherCAT slave station

D136-003-005 2 x EtherCAT master station, 1 x CAN, 1 x Profibus DP slave station

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923