K-WANG

Yokogawa OR8EFG KCl filled ORP sensor (IM12C07J01-01E)

Yokogawa OR8EFG KCl filled ORP sensor (IM12C07J01-01E)

Product positioning and core features

1. Core positioning

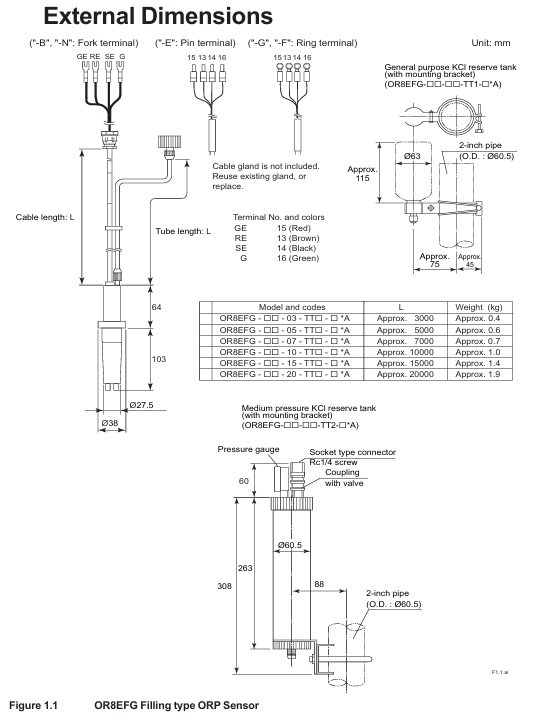

OR8EFG is a KCl filled ORP sensor based on metal electrode method, which achieves stable oxidation-reduction potential measurement (-1500~+1500 mV) by integrating platinum/gold indicator electrode and Ag/AgCl reference electrode, combined with KCl solution filling system. Its core advantage lies in its adaptability to multiple installation methods (immersion, flow, conduit suspension), and through pressure compensation design (medium pressure storage tank), it can be used under pressure conditions. It is also compatible with transmitters such as Yokogawa FLXA202/FLXA21, meeting the requirements of industrial measurement accuracy and reliability.

2. Core advantages

Wide working condition adaptation: supports a temperature range of -5~105 ℃ (slightly different depending on the material of the installation bracket), a pressure range of atmospheric pressure to 500 kPa (medium pressure storage tank), a medium flow rate of ≤ 2 m/s, and is suitable for various harsh processes;

Durable materials: PPS resin (main body), platinum/gold (indicator electrode), PTFE/ceramic (liquid interface), fluororubber/perfluoroelastomer (seal) are used for the contact medium components, which are acid and alkali resistant and corrosion-resistant;

Flexible installation: can be paired with PH8HS immersion bracket, PH8HF flow-through bracket, PH8HG catheter bracket, etc., or can be hung separately (maximum immersion depth of 3m) to adapt to different process layouts;

Compliance and Safety: Compliant with explosion-proof standards such as ANSI/ISA-60079 and IEC 60079, it can be used as a "simple device" in conjunction with isolated transmitters (such as FLXA202) for use in hazardous areas to avoid the risk of electrostatic ignition;

Low maintenance design: equipped with a KCl storage tank (universal type 250mL/medium pressure type), with low consumption of KCl solution (universal type ≤ 3 mL/day, PTFE liquid interface ≤ 20 mL/day), reducing the need for frequent fluid replenishment.

Detailed explanation of technical specifications

1. Basic measurement parameters

Parameter category specification details

ORP measurement range -1500~+1500 mV, measurement principle is metal electrode method, indicating electrode material can be platinum (- PT) or gold (- AU);

Environmental adaptability temperature: -5~105 ℃ (flow type bracket, stainless steel material), -5~80 ℃ (immersion bracket, PP material);

Pressure: normal pressure~500 kPa (medium pressure storage tank), normal pressure (universal storage tank);

Medium requirements: Conductivity is not mandatory, flow rate ≤ 2 m/s, maximum immersion depth 3m;

Contact material body: PPS resin (Ryton);

Indicator electrode: platinum glass/gold epoxy resin;

Liquid interface: ceramic/PTFE/fluororesin;

Sealing components: FKM/FFKM, suitable for organic solvents/high-temperature media;

KCl system storage tank: universal type (250mL, equipped with 2-inch pipe support), medium pressure type (requiring external pressure regulator);

Solution consumption: Under a pressure difference of 10 kPa, the universal liquid interface is ≤ 3 mL/day, and the PTFE liquid interface is ≤ 20 mL/day;

Cable: Chlorinated polyethylene rubber sheath, available in lengths of 3/5/7/10/15/20m;

The weight and protection of the sensor body are about 0.4kg, the general storage tank is about 0.3kg, and the medium pressure storage tank is about 1kg. There is no clear IP rating, but it can prevent liquid splashing through a sealed design (which needs to be used in conjunction with a bracket waterproof cap);

2. Model classification and suffix code

OR8EFG distinguishes core configurations through suffix codes, and the selection needs to specify electrode materials, cable lengths, storage tank types, and compatible transmitters. The specific meanings are as follows:

Core characteristics of suffix code classification

-PT/- AU indicator electrode PT: platinum electrode (universal scenario, oxidation resistant); -AU: Gold electrode (suitable for pollution prone scenarios such as sulfide);

-The numerical representation of the length of cables and KCl pipes, such as 03/-05/-10, is in meters. For example, -03 is 3m and supports a maximum length of 20m (100m can be customized);

-TT1/- TT2 storage tank type - TT1: universal type (250mL, normal pressure, equipped with pipeline support); -TT2: Medium pressure type (requires external air pressure, suitable for pressurized working conditions);

-TN1/- TN2 maintenance storage pipes only contain KCl supply pipes and do not include storage tanks (for pipeline replacement of existing storage tanks);

-E/- F/- G compatible transmitters - E: compatible with FLXA202/FLXA21/PH202 (pin terminals); -F: Compatible with FLXA202/FLXA21 (M3 ring terminal); -G: Compatible with FLXA402/PH450G (M4 ring terminal);

/TF//PF/FEP special options/TF: PTFE liquid interface (anti pollution); /PF: Perfluoroelastomer seal (resistant to organic solvents); /FEP: FEP material KCl tube (UV resistant);

3. Compliance and Explosion Protection Requirements

As a 'simple device', OR8EFG must meet the following compliance conditions before it can be used in hazardous areas:

Supporting equipment: It must be used in conjunction with transmitters with built-in isolation functions (such as FLXA202-D - □ - D-CB -...) or systems with isolation safety barriers to avoid risks introduced by non isolated circuits;

Temperature limit: Depending on the ambient temperature (Ta) and temperature level, the upper limit of the process temperature varies (for example, when T6 level Ta=40 ℃, FLXA202 can be used with an upper limit of 16 ℃); T3 level Ta=upper limit of 105 ℃ at 40 ℃);

Electrostatic protection: Avoid wiping the sensor with a dry cloth to prevent the accumulation of static electricity from causing explosions; The titanium material solution grounding terminal (- TN suffix) can eliminate the risk of impact friction sparks;

Installation and wiring process

1. Preparation before installation

(1) Unpacking and Inspection

After unpacking, confirm that the sensor body, indicator electrode, liquid interface, and KCl storage tank (if ordered) are not damaged, and verify that the model suffix matches the order (such as electrode material and cable length);

The indicator electrode and the liquid interface are packaged separately, and the liquid interface should be kept moist. After unpacking, it should not be taken out temporarily to avoid drying and affecting performance;

Check the integrity of attachments: installation bracket (such as PH8HS), KCl solution/powder (accessory OR8AX contains 3 bags of 250mL powder), cable sealing glass, etc.

(2) Installation site selection requirements

Avoid installing in dead zones, bubble accumulation areas, or locations with high flow rates (>2 m/s) to prevent measurement response delays or electrode wear;

If the medium contains corrosive gases (such as ammonia and hydrogen sulfide) or the temperature is greater than 80 ℃, a flow-through or immersion bracket must be used and cannot be suspended separately;

The installation in hazardous areas must comply with local electrical regulations (such as ANSI/ISA-RP12.06.01), ensure that the grounding resistance is ≤ 1 Ω, and avoid potential difference sparks.

2. Core installation steps (taking a flow-through bracket as an example)

(1) Assembly of electrode and liquid interface

Installation indicator electrode: Remove the sealing tape from the installation hole of the sensor body electrode, take out the platinum/gold electrode, check that the O-ring is not damaged, and then screw it clockwise into the installation hole until the O-ring is tightly sealed;

Pre installed liquid interface: Remove the sealing tape from the installation hole of the liquid interface, gently screw the liquid interface into 2-3 turns (not tightened temporarily), and reserve a channel for filling with KCl solution;

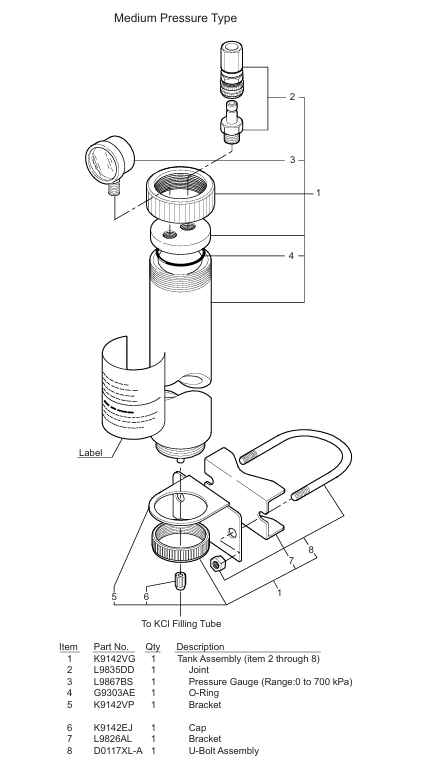

Connect KCl storage tank: If it is a universal type (- TT1), fix the storage tank on a 2-inch pipe through a bracket, connect the KCl supply pipe of the sensor, and use the accompanying needle to puncture the top of the storage tank (balance air pressure); If it is a medium pressure type (- TT2), an external air pressure regulator (slightly higher than the maximum process pressure) is required, and an air pipeline should be connected.

(2) KCl solution filling

Invert the sensor (below the height of the storage tank) to allow KCl solution to flow from the storage tank into the sensor body;

When the solution overflows from the installation hole of the liquid interface, tighten the liquid interface clockwise (to avoid residual air) to complete the filling;

The medium pressure storage tank needs to be replenished to a distance of 30-40 mm from the top to prevent the solution from overflowing during pressurization.

(3) Bracket assembly and fixation

Remove the protective foam of the circulating bracket (PH8HF), insert the sensor tip into the bracket, and tighten the fixing nut (ensure the O-ring compression seal);

Connect the process pipeline: first open the inlet valve, then open the outlet valve to avoid medium impact on the sensor; Under medium pressure conditions, the storage tank needs to be pressurized first before the process medium is introduced.

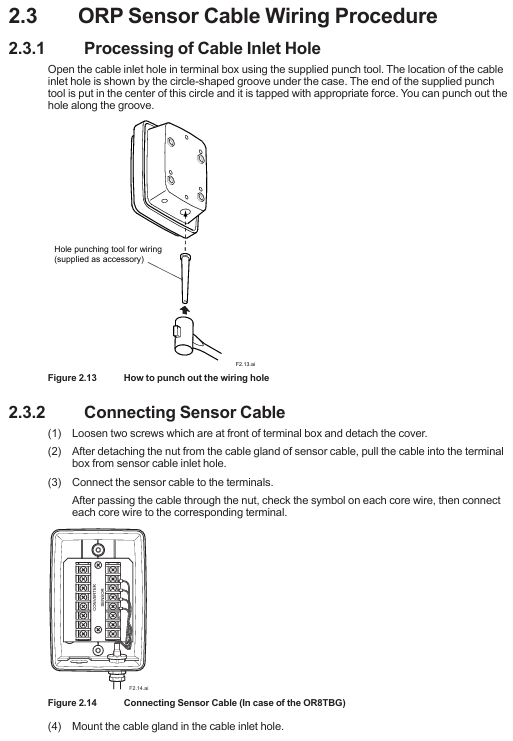

3. Wiring specifications

The OR8EFG cable contains 4-core wires and needs to be connected to the transmitter (such as FLXA202) according to the terminal definition. The wiring method may vary slightly depending on the terminal type (pin/ring):

Corresponding terminal for cable core color function (taking FLXA202 as an example) Remarks

The red indicator electrode (GE) at terminal 15 is transmitting ORP signals, and it is necessary to ensure that the wiring is secure to avoid signal interference;

The brown reference electrode (RE) terminal 13 forms a measurement circuit with the indicator electrode and needs to be grounded separately;

The black liquid interface/grounding (SE) terminal 14 is used to eliminate the grounding potential difference and must be reliably grounded;

Connect the green common terminal (G) 16 to the transmitter common terminal to ensure the integrity of the circuit;

Cable sealing: When passing through the transmitter cable inlet, a matching glass should be used, and the nut should be tightened to the seal (to avoid damaging the cable due to over tightening);

Explosion proof area: After wiring, it is necessary to confirm that the terminal box is sealed properly to prevent flammable gases from entering, and the grounding resistance should be ≤ 1 Ω.

Operations and Calibration

1. Daily maintenance

(1) KCl solution supplementation

Universal Liquid Storage Tank (- TT1): When the remaining solution is less than 1/4, replace with a new liquid storage tank (accessory K9084KQ), or supplement with a 3.3mol/L solution (246g KCl dissolved in 1L pure water) prepared with KCl powder (K9020XU) to avoid reference electrode failure caused by an empty liquid storage tank;

Medium pressure storage tank (- TT2): Close the process pipeline valve → Remove the pressure of the storage tank → Add KCl solution to the specified height → Re pressurize (slightly higher than the process pressure) → Open the process valve, and the replenishment cycle depends on the consumption (usually 1-2 months).

(2) Cleaning of electrode and liquid interface

Choose the cleaning method based on the type of medium contamination, only clean the sensor tip (to avoid damaging the cable/reservoir):

Suspended solids/viscous pollutants: Wipe with a soft tissue and rinse with pure water;

Oil/organic matter: Soak in neutral detergent solution (for tens of minutes to several hours), then rinse with pure water;

Metal adsorption/chemical stains: Soak in 1-2% dilute hydrochloric acid solution (several minutes), then rinse with pure water;

Liquid junction blockage: If the measurement response slows down, the liquid junction can be immersed in a 3mol/L KCl solution at 70 ℃ and naturally cooled to restore conductivity.

2. Calibration process

ORP sensors need to be calibrated regularly with quinone hydroquinone standard solution to ensure measurement accuracy. It is recommended to calibrate every 3-6 months (shortened for severe pollution scenarios):

(1) Calibration preparation

Prepare quinone hydroquinone powder (accessory K9024EC), pH buffer solution (such as pH 4.01/6.87), pure water, and clean the beaker;

Prepare standard solution: Dissolve 1g of quinone hydroquinone powder in 200mL of pH buffer and stir until saturated;

Clean the sensor: Follow the above cleaning method to clean the interface between the indicator electrode and the liquid, rinse with pure water, and dry dry.

(2) Two point calibration steps

First point calibration (pH 6.87 buffer solution):

Immerse the sensor in a quinone hydroquinone pH 6.87 standard solution and wait for the reading to stabilize (usually 5-10 minutes);

Enter the "ORP Calibration" mode according to the transmitter manual (such as FLXA202), and input the theoretical value (ORP=96 mV, rH=23.6 at pH 6.87);

Second point calibration (pH 4.01 or 9.18 buffer solution):

Rinse the sensor with pure water, immerse it in a quinone hydroquinone solution of another pH, and wait for it to stabilize before inputting the corresponding theoretical value (such as ORP=265 mV at pH 4.01);

Verification and reset: After calibration, immerse the sensor in pure water, confirm that the reading drift is ≤± 10 mV, and install it back into the process pipeline.

3. Replacement of vulnerable parts

(1) Liquid interface replacement

When the liquid interface is severely blocked (still unresponsive after cleaning) or damaged, it needs to be replaced (accessories K9142TH/TH, etc.):

Drain the KCl solution from the sensor and unscrew the old liquid interface counterclockwise;

Apply a small amount of KCl solution to the new liquid interface and gently screw it into the sensor body 2-3 times;

Refill the KCl solution until it overflows, tighten the liquid interface, and confirm that the solution seeps out from the liquid interface (visually or through a transmitter to detect impedance 2 ≤ 50 k Ω).

(2) Indicator electrode replacement

If the electrode surface is severely oxidized (with large reading drift and slow response), replace the platinum/gold electrode (accessory K9142TS/TT, etc.):

Remove the old electrodes from the sensor body and check if the O-ring is damaged (replace them together);

Apply silicone grease to the new electrode O-ring and screw it clockwise into the installation hole until it is sealed;

Refill KCl solution, calibrate and put into use.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector