K-WANG

Allen-Bradley IMC ™ S Class Compact Motion Controllers (IMC-S/23x model)

Allen-Bradley IMC ™ S Class Compact Motion Controllers (IMC-S/23x model)

Core positioning and basic functions of the product

IMC-S/23x is a compact, robust microprocessor based motion controller under Rockwell Automation Allen Bradley, supporting 2-axis or 4-axis servo control, integrating logic and field power, and can be used as an independent motion and logic controller without additional accessories, suitable for various industrial scenarios. Its core function revolves around closed-loop motion control, which requires external drive systems and feedback encoders to achieve various high-precision motion controls, including:

Single point positioning control: supports three speed profiles: trapezoidal, parabolic, and S-shaped, and can independently program speed, acceleration, and deceleration parameters to meet smooth start stop requirements under different operating conditions.

Multi axis interpolation function: Supports up to 3-axis linkage, achieving linear, circular, and spiral interpolation, suitable for complex trajectory motion scenes (such as precision machining path control).

Synchronous control capability: equipped with electronic gear and electronic cam functions, the electronic gear can make any shaft follow the main axis in a programmable proportion (proportion supports floating point or fractional form); Electronic cam can generate collaborative motion profiles based on time or main axis position, and can also be combined with phase shift, automatic positioning, and automatic correction functions to simplify complex synchronous motion programming.

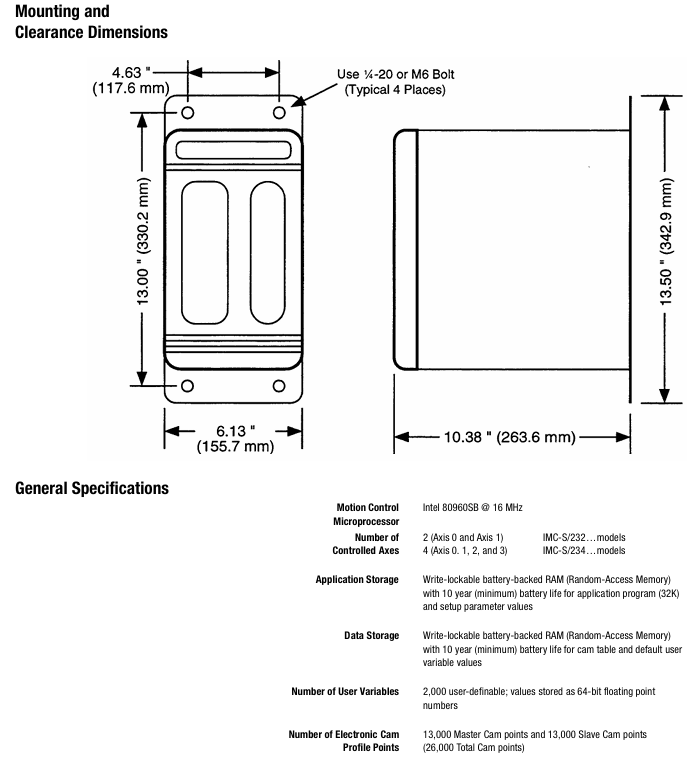

Hardware configuration and specifications

(1) Core hardware parameters

Category specific parameters

The microprocessor Intel 80960SB operates at a frequency of 16MHz and adopts RISC architecture to ensure high-speed data processing and motion computing

Axis configuration includes 2 axes (IMC-S/232 model) and 4 axes (IMC-S/234 model)

Feedback and output encoder input supports incremental AB orthogonal signals, with a maximum feedback count rate of 4MHz, ensuring accuracy under high-speed motion; The servo output is an isolated 16 bit DAC, supporting ± 10V voltage or ± 150mA current mode, and can be independently configured by axis

Storage configuration applications and parameter storage use RAM (non-volatile) with battery backup, with a battery life of at least 10 years; Can store 32K applications, 13000 main cam points+13000 slave cam points, support 2000 64 bit floating-point user variables

Environmental adaptability: Operating temperature range of 0-50 ℃, storage temperature range of -40-70 ℃, maximum humidity of 95% (non condensing), suitable for complex industrial environments

Power requirements: AC input 90-132V/175-264V (47-63Hz, maximum 3A), I/O power supply 5-40V DC (nominal 24V DC, maximum 3A), all equipped with 3A slow melting fuse protection

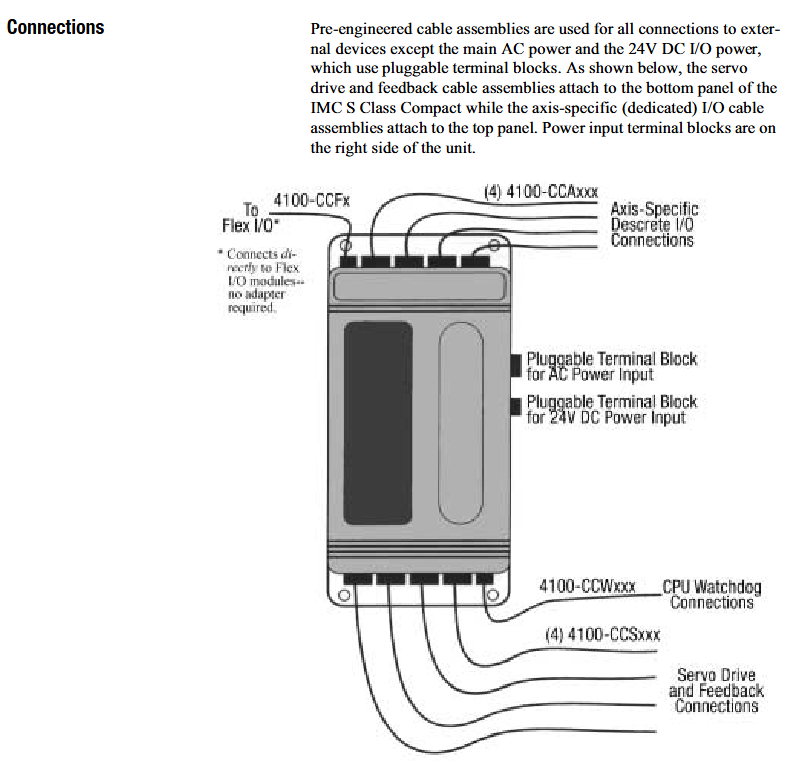

(2) I/O interface configuration

The dedicated discrete I/O: 2-axis model includes 10 inputs (5 per axis, corresponding to origin switch, positive and negative overtravel switch, driver fault, position positioning signal) and 4 outputs (2 per axis, corresponding to driver enable, absolute position trigger); The 4-axis model has 20 inputs and 8 outputs, all of which are designed with optical isolation. The output includes relay contacts (driver enabled) and solid-state relays (position triggered).

Extended I/O support: can directly connect up to 8 Allen Bradley Flex devices ™ I/O module, with a total of 128 discrete I/O points, can also be replaced with analog I/O modules (such as 8-channel analog input and 4-channel analog output modules) to meet different signal acquisition and control requirements, and can be directly connected without the need for additional adapters for use.

Software and Programming

(1) Programming environment

Using Allen Bradley's proprietary GML (Graphic Motion Control Language) for application programming, providing over 100 instructions and allowing for complete customization of controller functions; Equipped with a graphical development system, it supports real-time debugging, reduces programming difficulty, and supports multitasking operating systems. It can execute up to 10 tasks simultaneously, improving system efficiency.

(2) Program Download and Storage

Download programs to the controller through RS-232C or RS-422 ports, store them in non-volatile RAM, and have a "Memory Lock" key switch on the panel to prevent accidental operation or unauthorized modification of programs and parameters.

Communication function

The controller is equipped with multi-channel communication interfaces, supporting flexible interconnection with external devices, including:

Serial communication: 2 serial ports (A/B), can be independently configured as RS-232C or RS-422 (optical isolation), RS-232C has a maximum baud rate of 19.2k, RS-422 has a maximum baud rate of 128k; port B can be replaced with DH-485 channel (half duplex, baud rate of 9.6k/19.2k, RJ-45 interface), used for human-machine interface (MMI) connection, supports ASCII encoding and XON/XOFF flow control.

Remote I/O option (IMC-S/23x-R model): Supports remote I/O communication with other Allen Bradley devices (such as PLCs), supports discrete signal and block transmission, with a maximum block transmission length of 64 words (128 bytes), and supports multiple data formats such as 32-bit integers and 32-bit floating-point numbers; The rack address can be selected between 0-31, and the rack width supports 1/4, 1/2, 3/4, and full rack configurations, corresponding to different I/O points (such as a full rack with 100 inputs and 100 outputs).

AxisLink option (IMC-S/23x-L model): used for real-time axis collaboration between multiple controllers, supports 1Mbps baud rate, uses Allen Bradley 1770-CD RIO cable (or equivalent cable), with a maximum total cable length of 25 meters (minimum 1 meter between controllers); Up to 8 controllers can be connected (32 axes in total, with expansion nodes supporting 16 controllers and 64 axes), supporting virtual spindle functionality (up to 1 controller per controller for a total of 4), with a maximum of 31 slave axes per virtual spindle, and a discrete I/O response time of ≤ 1ms.

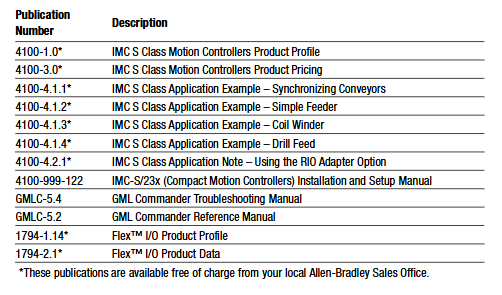

Model and accessories

(1) Model Interpretation

In the IMC-S/23x model format, the meanings of each part are as follows:

2 ": Represents a Stand Alone platform;

3 ": represents Compact Package;

Axis number: "2" represents 2 axes, "4" represents 4 axes;

Options: "R" represents Remote I/O adapter, "L" represents AxisLink multi axis synchronous link.

(2) Specialized cable accessories

Provide pre designed cable components to simplify external device connections. Common cables are listed in the table below:

Product catalog number, usage, length (feet/meters), required quantity per device

4100-CCF1/4100-CCF3 connection Flex I/O module 1/0.3, 3/1, 1 per controller (only required when using Flex I/O)

4100-CCS15F connects servo drive and feedback device 15/4.5, 1 per axis

410P-CAQB connection 1391B-ES/1391-DES driver with no fixed length, 1 per axis

4100-CCA15F connection dedicated discrete I/O 15/4.5, 1 per axis

4100-CCW15F connected CPU watchdog 15/4.5, 1 per controller

4100-RCS3T connection 4100-REC 3/1, 1 per axis (only required when using 4100-REC)

Safety and Diagnosis

Security protection function: equipped with encoder loss detection (to prevent feedback faults from causing equipment damage), programmable position locking and position error tolerance (servo fault protection), software direction travel limit (to prevent overtravel); The CPU watchdog is equipped with a panel LED indicator to ensure timely alarm in case of system failure.

Diagnosis and debugging: Built in hook up diagnostic function and automatic servo setting program, which can quickly complete servo parameter self-tuning; The panel LED can intuitively display the status of power, memory, etc., simplifying troubleshooting.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923