K-WANG

Bentley Baker Hughes 2300 Series Vibration Monitors

Bentley Baker Hughes 2300 Series Vibration Monitors

Product core positioning and application scenarios

The 2300 series vibration monitor is an industrial grade online vibration monitoring device launched by Baker Hughes. Its core function is to real-time collect and analyze vibration data of rotating machinery (such as motors, pumps, compressors, turbines, etc.), accurately monitor vibration amplitude and frequency, timely identify abnormal vibration states of equipment, trigger alarms or shutdown protection, ultimately prevent mechanical failures, extend equipment life, and ensure the continuity and safety of industrial production processes. Its typical application scenarios cover fields such as oil and gas, chemical, power, manufacturing, etc., and are suitable for 24-hour uninterrupted status monitoring of key rotating equipment.

Product Model and Core Classification

The 2300 series includes multiple sub models, which can be divided into two core categories based on monitoring functions and signal types to meet different monitoring needs:

Model Category Core Monitoring Parameters Key Features Applicable Scenarios

2301/2302 single channel vibration monitor 2301: Radial vibration (Velocity/Displacement); 2302: Axial vibration (Thrust Position) single channel independent monitoring, supports 4-20mA analog output, can be configured with local alarm lights, compact structure, only needs to monitor equipment with a single vibration dimension (such as small motor radial vibration, pump axial thrust monitoring)

2303 dual channel vibration monitor simultaneously monitors 2-path vibration (Velocity/Displacement), or 1-path+1-path axial vibration. The dual channel integrated design reduces installation space and supports vibration difference monitoring (such as wheel misalignment analysis). The alarm logic is more flexible and critical equipment that requires simultaneous monitoring of multidimensional vibration (such as radial and axial joint monitoring of compressors and turbines) needs to be monitored simultaneously

Technical specifications and performance parameters

(1) Core parameters for vibration monitoring

Specific specifications for parameter categories

Measurement range velocity: 0-20 mm/s (RMS, RMS); Displacement: 0-200 μ m (peak to peak, PP); Axial position (Thrust): 0-500 μ m (peak to peak) supports users to customize the range according to device types (such as low-speed motors, high-speed turbines), meeting the vibration characteristics requirements of different devices

Frequency response 5-1000 Hz (standard range); Optional 1-1000 Hz (low-frequency extension) covers the vibration frequency range of the vast majority of industrial rotating equipment (such as motor frequency vibration, bearing fault high-frequency vibration), ensuring the integrity of monitoring data

Accuracy level ± 2% of full scale (at 25 ℃ ambient temperature); ± 3% full range (0-60 ℃ working temperature range) high measurement accuracy ensures the accuracy of abnormal vibration identification, avoiding false alarms or missed alarms

Input signal type compatible with ICP ® Type accelerometer (with built-in charge amplifier, requiring 24V DC excitation); Or piezoelectric acceleration sensors (requiring external charge amplifiers) support mainstream industrial vibration sensors, reducing the compatibility cost of upgrading or replacing user devices

(2) Electrical and Environmental Specifications

Power requirements: 18-30V DC (standard), or 85-265V AC (optional AC power supply module), power consumption ≤ 5W (no alarm state), with overvoltage and overcurrent protection functions, suitable for unstable power supply environments in industrial sites.

Output signal:

Analog output: 4-20mA isolated output (independent for each channel), load resistance 0-500 Ω, can be directly connected to DCS, PLC or SCADA system for remote data monitoring.

Switching output: 2 sets of SPDT (single pole double throw) relay outputs (1 set per channel/monitoring dimension), rated load 250V AC/5A or 30V DC/5A, used for local alarm (such as sound and light alarm lights) or equipment shutdown control.

Environmental adaptability: working temperature -20-60 ℃, storage temperature -40-85 ℃, relative humidity 0-95% (no condensation), protection level IP65 (panel installation part), can withstand harsh conditions such as dust, humidity, and vibration in industrial sites.

Installation method: Panel embedded installation (standard 1/4 DIN size, i.e. 96 × 48mm panel opening), installation depth ≤ 150mm, suitable for compact layout inside control cabinets.

Core functions and operational design

(1) Monitoring and protection functions

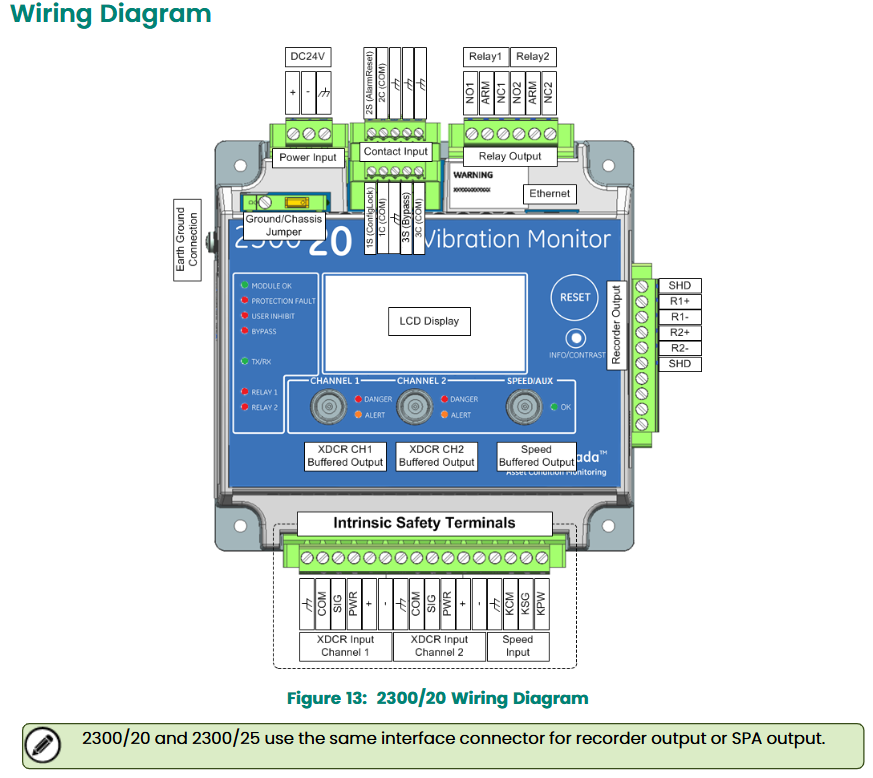

Multi level alarm setting: Supports 2-level alarm thresholds ("Warning", "Danger"), users can configure specific values through panel buttons or software (such as speed warning value of 10 mm/s, danger value of 15 mm/s), alarm status triggers external response through relay output, and panel LED lights (red=danger, yellow=warning, green=normal) intuitively display device status.

Vibration trend recording: Some models have built-in data storage function, which can record the maximum and average vibration trend in the past 30 days (sampling interval can be set between 1-60 minutes). It supports exporting data through RS485 communication (Modbus RTU protocol) for equipment fault tracing and life prediction analysis.

Fault diagnosis assistance: Some high terminal models (such as 2303-D) support vibration frequency spectrum analysis (with specialized software), which can identify common fault characteristic frequencies (such as bearing inner ring fault frequency, unbalanced vibration frequency), helping operation and maintenance personnel locate the root cause of the fault (such as "imbalance", "misalignment", "bearing wear").

(2) Operation and Configuration

Local operation: The panel is equipped with 4 tact buttons (menu, confirm, increase/decrease), paired with a 2-line 16 character LCD display screen, which can directly set parameters such as range, alarm threshold, sampling interval, etc. without the need for external tools, making it convenient for on-site debugging.

Remote configuration: Supports connecting to upper computers (such as computers and HMIs) through RS485 communication interface (Modbus RTU protocol), using Baker Hughes dedicated configuration software (such as "VibroLink") for parameter settings, data reading, and trend analysis, suitable for centralized management of batch devices.

Hardware Design and Accessories

(1) Hardware structure characteristics

Isolation design: Optoelectronic isolation (isolation voltage 2500V AC, 1 minute) is used between input signals, analog output, and power supply to effectively suppress electromagnetic interference (EMI) in industrial sites, ensure stable monitoring data, and avoid misoperation caused by external interference.

Redundancy protection: The relay output has a "Fail Safe" mode, which can be set to "alarm when power is off" or "normal when power is off" to prevent the device from losing protection due to monitor power failure; Some models support sensor open/short circuit detection. When the sensor fails, it immediately triggers a "sensor failure" alarm, prompting operation and maintenance personnel to troubleshoot.

(2) Supporting accessories

Sensor: Recommended to be paired with Baker Hughes 3300 series ICP ® Acceleration sensors (such as 330103 radial sensors and 330180 axial sensors) provide a complete solution of "monitor+sensor" to ensure signal matching and stability.

Communication and connection accessories: Provide RS485 communication cables (model 2300-CAB), sensor extension cables (model 3300-CAB), and panel mounting brackets (model 2300-MNT) to simplify on-site installation and wiring.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923