K-WANG

REXRTOH INDRAMAT TVD 1.3 power module

REXRTOH INDRAMAT TVD 1.3 power module

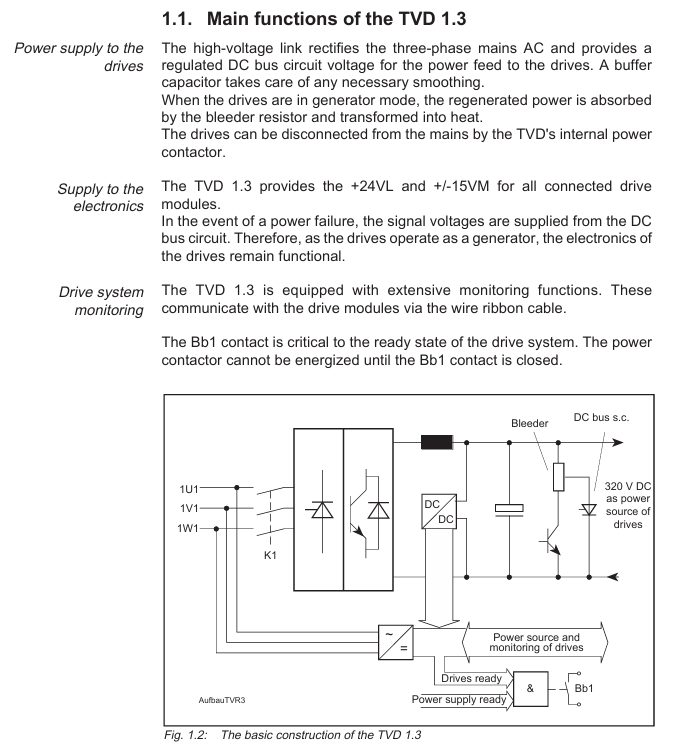

Product positioning: TVD 1.3 is the power module of INDRAMAT modular AC drive system, which is directly connected to the three-phase 380-480V power grid, rectifies the AC power into a stable DC bus voltage (320V DC), supplies power to the drive module, and processes the regenerated electrical energy of the motor to provide control voltage for electronic components.

Core specifications and functional features of the product

1. Key electrical parameters

TVD 1.3 offers two power specifications (7.5kW and 15kW continuous DC bus power), with the core parameters compared as follows:

Parameter category TVD 1.3-08-3 (7.5kW) TVD 1.3-15-3 (15kW) Unit

Input specifications 3 × AC 380-480V (± 10%), 50-60Hz with the same left V/Hz

DC bus voltage of 320 (± 5%) is the same as the left V DC

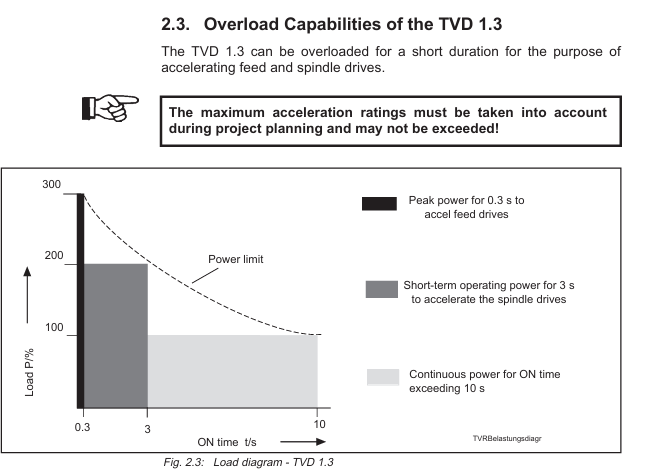

Continuous DC bus power 7.5 15 kW

Short time DC bus power (3s, spindle drive acceleration) 15 30 kW

Peak DC bus power (0.3s, feed drive acceleration) 22.5 45 kW

Discharge resistor continuous power 0.5 1 kW

Peak power of discharge resistor 20 40 kW

Maximum regenerative energy 30 60 kW · s

Control voltage output+24V (4.9A), ± 15V (+15V: 2.5-5.1A; -15V: maximum 2A, total ≤ 4A) same as left V/A

Working temperature range: 0-45 ℃ (rated data), -25-55 ℃ (storage and transportation), same as left ℃

Protection level IP 10 (compliant with DIN 40050) same as left-

Weight 10.5 11.2 kg

2. Core functional features

Rectification and voltage stabilization: Rectify three-phase AC power into 320V DC stable DC bus voltage, which can maintain driving dynamic performance even if the grid voltage fluctuates.

Regenerated electrical energy processing: When the motor is in power generation mode, the regenerated electrical energy is converted into thermal energy through internal discharge resistors; External auxiliary release module (TBM 1.2) can be used to enhance processing capacity.

Built in protection mechanism:

Overcurrent protection: When the DC bus is short circuited or overloaded, quickly cut off the output;

Overvoltage protection: When the DC bus voltage exceeds the limit, it triggers a shutdown;

Over temperature protection: When the temperature of the heat sink is too high, a warning should be given first (power off after 30 seconds) to avoid module damage;

Short circuit protection: When the output circuit is short circuited, the internal circuit automatically cuts off the faulty channel without affecting other channels.

Power supply for electronic components: Provide+24V (load voltage) and ± 15V (measurement voltage) for all connected drive modules. In case of power failure, temporary power supply is provided by the DC bus to ensure the functionality of the driving electronic components.

Flexible control and redundancy: supports dynamic braking of DC bus (synchronous motor with short-circuit bus braking in case of fault), and can be configured with external jumper to drive the braking mode after power failure; Support redundant configuration to enhance system reliability.

Electrical Connection and Installation Specification

1. Core connection configuration

TVD 1.3 needs to be used in conjunction with supporting components, and there are two main connection methods:

Compact configuration (including NAM 1.3 module): NAM 1.3 is an integrated power connection module with built-in commutation choke, buffer capacitor, and DC bus smoothing choke to reduce wiring workload. It is compatible with TVD 1.3-08 (with NAM 1.3-08) and TVD 1.3-15 (with NAM 1.3-15).

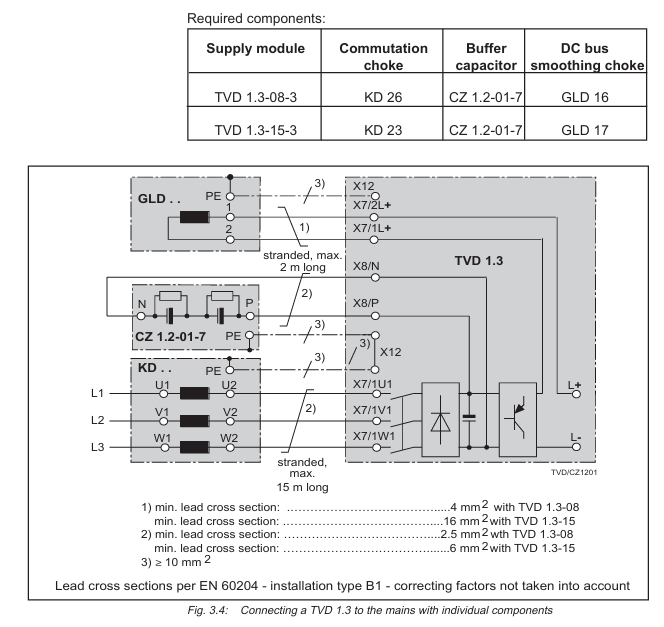

Distributed configuration (independent components): It is necessary to separately connect the commutation choke (KD 26/23), buffer capacitor (CZ 1.2-01-7), and smoothing choke (GLD 16/17), which are suitable for space limited or special working condition scenarios.

2. Key wiring requirements

Main power supply wiring: three-phase 380-480V connected to terminal X7 (1U1/1V1/1W1), with a wire cross-sectional area of ≥ 10mm ² (copper core, rated at 75 ℃), requiring gL type fuses (maximum 35A) or circuit breakers (15A/30A, corresponding to 7.5kW/15kW).

DC bus wiring: Connect the drive module through a bus bar, with a wire cross-sectional area of ≥ 4mm ² (7.5kW) or 10mm ² (15kW), and a maximum wiring distance of 1 meter. Twisted pair cables are required to reduce interference if exceeded.

Control signal wiring: 16 pin bus cable (X1 terminal) is used for communication and power supply of the drive module, and a terminal plug is required to start the high-voltage part; The control terminals (X2/X3/X4/X5) are used for brake control, fault signal output, etc., with a wire cross-sectional area of ≤ 2.5mm ².

3. Installation requirements

Cabinet installation: The module protection level is IP 10 and needs to be installed in a closed cabinet with a temperature of ≤ 45 ℃ and humidity of ≤ 95% (no condensation);

Heat dissipation space: At least 80mm of ventilation space should be reserved above and below the module, and flammable materials (such as cables) should not be placed within 300mm around the discharge resistor;

Grounding specification: It is necessary to connect the cabinet PE guide rail, and the cross-sectional area of the grounding wire should be ≥ 10mm ² (copper core), ensuring that the grounding resistance is ≤ 4 Ω;

Altitude adaptation: When the altitude exceeds 1000 meters, the power usage should be reduced according to the derating curve (such as reducing the power to 80% at 2000 meters).

Troubleshooting and Maintenance

1. Fault diagnosis and localization

The front panel of the module is equipped with LED diagnostic lights, which indicate the type of fault through different colors (green/red/flashing). The core faults and troubleshooting methods are as follows:

Fault type LED indication Possible causes Troubleshooting methods

Control voltage fault (+24V/± 15V)+24V/± 15V, red light, electronic power supply loss, load exceeding upper limit, check main fuse, disconnect bus to detect voltage, reduce load

Drive or power failure Bb1 red light drive module failure, loose bus connection check drive diagnosis, re plug and unplug bus cable, confirm terminal plug installation

Overcurrent fault I-FAULT light red DC bus short circuit, motor cable damage, disconnection of drive connection, detection of bus insulation, replacement of damaged cable or drive

Release overload P-FAULT light red regeneration energy over release capability, increase auxiliary release module (TBM), reduce driving and braking frequency

Overheating fault T-FAULT light red, poor heat dissipation, high ambient temperature. Clean the heat dissipation channel, improve cabinet ventilation, and reduce module load

Overvoltage fault U-FAULT light red grid voltage too high, rectifier circuit fault check grid voltage (≤ 480V ± 10%), replace module

2. Maintenance and replacement standards

Regular maintenance: Check the tightness of the wiring terminals and the cleanliness of the heat sink every 6 months, and measure the insulation resistance (≥ 10M Ω) annually;

Module replacement: After power off, wait for 5 minutes (capacitor discharge), confirm that there is no voltage, remove the wiring, replace with a module of the same model (matching power and version), and test the bus communication and voltage output after rewiring.

Selection and ordering information

1. Core component model

Component category, model, and specification description

Power module TVD 1.3-08-3 7.5kW continuous DC bus power, 320V DC output

TVD 1.3-15-3 15kW continuous DC bus power, 320V DC output

Integrated connection module NAM 1.3-08 compatible with TVD 1.3-08, including commutation choke/buffer capacitor

NAM 1.3-15 is compatible with TVD 1.3-15, including commutation choke/buffer capacitor

Auxiliary release module TBM 1.2-040-W1 enhances release capacity (1.5kW continuous/60kW peak)

Independent component KD 26/23 commutation choke (15A/30A)

CZ 1.2-01-7 Buffer Capacitor (1mF/700V)

GLD 16/17 DC bus flat wave choke coil (25A/50A)

2. Ordering precautions

The power module should be selected based on the total power of the drive (continuous power should cover the sum of the rated power of all drives);

If the drive frequently starts, stops, or brakes, an additional auxiliary release module (TBM) or DC bus capacitor needs to be configured;

High altitude (>1000 meters) or high temperature (>40 ℃) environments require the selection of downgraded models or strengthened heat dissipation measures.

Safety and Compliance Instructions

Hazardous Area Use: Only applicable to Class I, Zone 2 hazardous environments (non flammable areas), prohibited for use in explosive environments;

Voltage safety: There is a maximum of 450V DC high voltage inside the module. After power failure, it is necessary to wait for 5 minutes for discharge, and only certified electricians are allowed to operate;

Compliance standards: comply with UL standards, DIN 40050 (protection level), EN 60204 (electrical installation) and other specifications, and confirm the compatibility with local electrical regulations before use.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB AX411/511010/STD pH/ORP Analyzer Controller

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923