K-WANG

BENDER ISOMETER ® IRDH265/365 series insulation monitoring equipment

BENDER ISOMETER ® IRDH265/365 series insulation monitoring equipment

Product Overview

BENDER ISOMETER ® The IRDH265/365 series is an insulation monitoring device developed by Bender, a German company, specifically for IT AC systems, IT AC systems with directly connected DC circuits, and IT DC systems (isolated power supplies). Its core mission is to monitor the insulation resistance status between system conductors and the earth (PE) in real time, and to provide timely warning of insulation faults through a graded alarm mechanism, ensuring the safe and stable operation of electrical systems under complex working conditions. This series of products, with patented measurement technology, flexible adaptability, and comprehensive functional configuration, are widely used in industrial scenarios containing rectifiers, converters, thyristor controlled DC drivers, and other components. They fully comply with multiple international universal standards and have high reliability and strong compatibility.

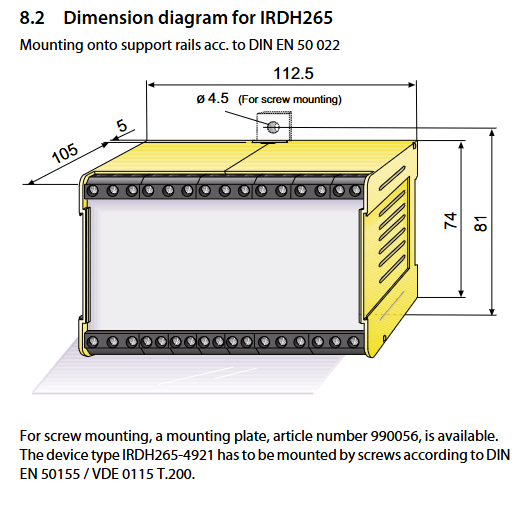

The series includes two core models: IRDH265 (standard plastic housing, supporting DIN rail installation or screw installation) and IRDH365 (embedded housing, 144x72mm size, compatible with panel embedded installation). The functional parameters of the two are the same, with only differences in installation methods and mechanical specifications, which can meet the needs of different installation scenarios.

Core adaptation range

(1) System type adaptation

Basic adaptation system: IT communication systems such as 3AC, 3 (N) AC, single-phase AC, etc; Pure IT DC system

Special adaptation system: IT AC system with direct connection to DC circuit (such as AC system with DC load including rectifier, converter, thyristor controlled DC driver, etc.)

Adaptation prerequisite: In the DC circuit directly connected to the AC system, the rectifier needs to carry a load current of>5... 10mA to ensure accurate monitoring of DC circuit insulation faults

(2) Voltage parameter specifications

Rated monitoring voltage: AC 0... 793V (frequency 50... 400Hz, reference to characteristic curve when frequency<50Hz); DC 0... 650V (slightly different sub series, such as -7 series DC maximum 750V, -8 series DC maximum 650V)

Extended monitoring voltage: It can be extended to higher levels through a dedicated coupling device, with specific adaptations as follows:

AGH204S-4: Suitable for AC 0... 1650V (without rectifier), AC 0... 1300V (with rectifier, DC maximum 1840V)

AGH520S: Suitable for AC 0... 7200V

AGH150W-4: Suitable for DC 0... 1760V

Power supply voltage requirements: Provide multi specification power supply adaptation to meet the power supply needs of different scenarios:

Power type, voltage range, applicable model examples

AC power supply 230V (50... 60Hz) IRDH265-4, IRDH365-4

AC power supply 90... 132V IRDH265-413, IRDH365-413

AC power supply 400V IRDH265-415, IRDH365-415

AC power supply 500V IRDH265-416, IRDH365-416

DC power supply 19.2... 84V IRDH265-422, IRDH365-422

DC power supply 77... 286V IRDH265-423, IRDH365-423

DC power supply 10.5... 80V IRDH265-R421, IRDH265-4921

Power protection: The power input terminal should be equipped with a short-circuit protection device according to the IEC 60364-4-473 standard, and it is recommended to use a 6A fuse

Core technology and functional characteristics

(1) Measurement principle (four levels optional to meet different system requirements)

AMP measurement principle (default): Bender's patented "adaptive measurement pulse" technology superimposes a pulsating AC measurement voltage with a peak value of 27V (positive and negative pulse amplitudes are consistent), and the measurement period dynamically adjusts with the system's leakage capacitance and insulation resistance. It is suitable for AC/DC hybrid systems, especially for complex scenarios containing a large number of DC components, with a maximum measurement current of 230 μ A.

DC measurement principle: Overlay 27V DC measurement voltage, only applicable to pure AC systems, insufficient sensitivity for DC insulation fault monitoring, not recommended for use in hybrid systems.

UG/AMP measurement principle: Passive asymmetric measurement (without DC measurement voltage), only applicable to pure DC systems. Fast response is achieved by detecting the DC current and residual voltage generated by L+/L - asymmetric faults. After the alarm is triggered, it automatically switches to the AMP principle to measure insulation resistance. AMP measurement is performed every hour to detect symmetric faults.

AMP/UG measurement principle: AMP measurement is combined with asymmetric measurement. The faults detected by AMP principle are fed back through ALARM2, while those detected by asymmetric measurement are fed back through ALARM1. It is suitable for scenarios that require differentiation of different fault types.

(2) Basic core functions

Insulation monitoring and graded alarm:

Dual level adjustable response values: -3 series 40k Ω/10k Ω, -4 series 180k Ω/40k Ω, -7 series 600k Ω/300k Ω, -8 series 1M Ω/500k Ω (all factory default, adjustable through menu, -3/-4 series adjustment range 10k Ω... 990k Ω), with a hysteresis of approximately 25%.

Fault type differentiation: Supports identification of AC faults and DC faults (including L+/L - single pole faults), and alarm triggering conditions can be set through the Setup 2 menu (only AC, only DC, both AC/DC triggered, etc.).

Alarm output: 2 conversion contact relays, supporting N/O (default) or N/C operation modes, rated contact voltage AC 250V/DC 300V, maximum switching current 5A, adjustable flashing function (1Hz pulse frequency).

Alarm indication: Two yellow alarm LEDs (ALARM1/ALARM2), corresponding to two levels of alarms, will light up intuitively when there is a fault.

Automatic adaptation and self-monitoring:

Leakage capacitance adaptation: The -3/-4 series can adapt to a maximum of 500 μ F, while the -7/-8 series can adapt to a maximum of 2 μ F. The equipment automatically adapts to changes in system leakage capacitance without affecting measurement accuracy.

Automatic self-test: The -3/-4 series automatically performs a self-test every 24 hours (with the alarm relay set to system fault alarm mode), triggered when the insulation resistance exceeds 20 times the maximum response value.

Manual self-test: Press and hold the TEST button (>2s) to start. When there are no faults, it displays "TEST OK R<1k Ω", the alarm relay acts, and the LED lights up; When a fault is detected, it displays "TEST ALARM". Press the RESET button (<1s) to clear the fault indication.

Connection monitoring: The -3/-4 series comes standard with a connection monitoring function that continuously monitors the connection status between the device and the IT system or PE. When there is a disconnection or high resistance, it displays "ALARM E-KE" (PE connection fault) or "ALARM L1-L3" (system connection fault), which can be turned off in the Setup 2 menu (recommended for new or small systems).

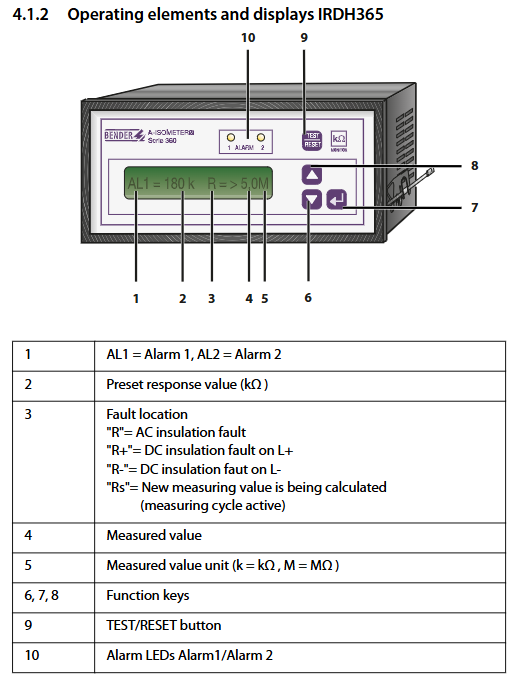

Display and operation:

Display configuration: LCD display screen, supporting the display of measurement values (unit k Ω/M Ω), response values, fault types (R=AC fault, R+=L+fault, R -=L - fault), menu parameters, etc.

Operation buttons: Both IRDH265/365 are equipped with function buttons (parameter adjustment, menu switching) and a combination TEST/RESET button (short press reset, long press test), supporting external test/reset buttons (cable length ≤ 10m).

Parameter storage: Set parameters to be stored in non-volatile memory (EEPROM) without loss during power failure; Short circuiting the LT terminal can store fault indications, and no faults are stored when the terminal is disconnected.

(3) Extended functions (configured through the Setup 2/Setup 3 menu)

Menu grading configuration:

Setup 1 (basic function): Set alarm response values, relay operation modes (N/O/N/C), password query, jump to Setup 2.

Setup 2 (Extended Function): Configure alarm fault types, coupling device parameters, connection monitoring switches, alarm flashing function, relay test switches, alarm time delay (1... 10s), maximum leakage capacitance matching, password activation and modification, restore factory settings, and view software versions.

Setup 3 (Measurement Principle): Select the measurement principle (AMP/DC/UG/AMP/AMP/UG) and set the DC fast response current level (0.1... 5mA).

Password Protection: Supports activating a two letter password to prevent unauthorized modification of parameters. Passwords can be set and reset in the Setup 2 menu.

System fault handling: When the LCD displays "TEST ALARM", the device needs to be powered off for a moment before restarting. If the fault still exists, it is highly likely to be a fault of the device itself and requires maintenance.

Status word display: Press and hold the IRDH265 function key for ≥ 5 seconds to display the status word, which includes key configuration information such as relay mode, alarm function, connection monitoring status, measurement principle, etc.

(4) Interface and communication functions

RS-485 interface: No electrical isolation, compliant with EIA R5-485 standard, terminal A/B wiring, maximum transmission distance of 1200m, transmission protocol of 9600 Baud (1 start bit+8 data bits+1 stop bit), continuous transmission of measurement values, alarm status and other data blocks, cannot be interrupted by other bus members.

External indication interface: The M+/M - terminal supports external k Ω measuring instruments (0... 400 μ A analog output), and this interface has no electrical isolation. When connecting to the process control system, an additional isolation module (such as RK170) needs to be configured.

Mechanical specifications and environmental adaptability

(1) Mechanical specifications

Model shell type, installation method, panel opening size (mm), compatible wire specifications, protection level, weight

IRDH265 XM112 (halogen-free) DIN rail installation (DIN EN 50022) or screw installation (accessory 990056 required) - rigid conductor 0.2... 4mm ², flexible conductor 0.2... 2.5mm ² (compatible with AWG 24... 12) shell IP30, terminal IP20 approximately 825g

IRDH365 X300 (halogen-free) embedded installation 138 × 66 rigid conductor 0.2... 4mm ², flexible conductor 0.2... 2.5mm ² (compatible with AWG 24... 12) shell IP30, terminal IP20 approximately 1075g

Installation note: Only one active ISOMETER is allowed to be connected to each interconnected system in the IT system ®; Terminals E and KE need to be connected to PE through separate wires, and this connection cannot be disconnected during equipment operation; The installation distance between adjacent devices should be ≥ 10mm (ventilation gap should be reserved when the temperature is>40 ℃).

(2) Environment and anti-interference performance

Working temperature: -10...+55 ℃ (standard version), -15...+55 ℃ (some models), -25...+70 ℃ (T option version)

Storage temperature: -40...+70 ℃ (standard version), -45...+85 ℃ (T-option version), display screen function is only guaranteed above -40 ℃

Climate grade: IEC 60721-3-3 3K5 (no condensation, no icing)

Anti interference performance: compliant with EN 50082-2 (anti electromagnetic interference), EN 55011/CISPR11 (electromagnetic emission, Class A, Suitable for industrial scenarios)

Mechanical anti-interference: anti impact 15g/11ms (standard version), 30g/11ms (T-option version); Anti collision 40g/6ms; Anti vibration 10... 150Hz/0.15mm-2g (standard version), 1.6mm/10-25Hz+4g/25... 150Hz (T-option version)

Flame retardant rating: XM112 shell UL94V-0, X300 shell UL94V-1

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923