K-WANG

BENDER ISOMETER ® IRDH375 series Insulation Monitoring Equipment

BENDER ISOMETER ® IRDH375 series Insulation Monitoring Equipment

Product Overview

BENDER ISOMETER ® The IRDH375 series is an insulation monitoring device developed by Bender, a German company, specifically for ungrounded alternating current (AC), mixed AC/DC, and direct current (DC) systems (i.e. IT systems). Its core mission is to monitor the insulation resistance status between the system conductor and the ground in real time, warn of insulation faults in a timely manner, and ensure the safe and stable operation of electrical systems. This series of products, with patented measurement technology, flexible adaptability, and comprehensive functional configuration, are widely used in various scenarios with strict electrical safety requirements, and fully comply with multiple international universal standards, possessing high reliability and compatibility.

Core adaptation range

(1) System type adaptation

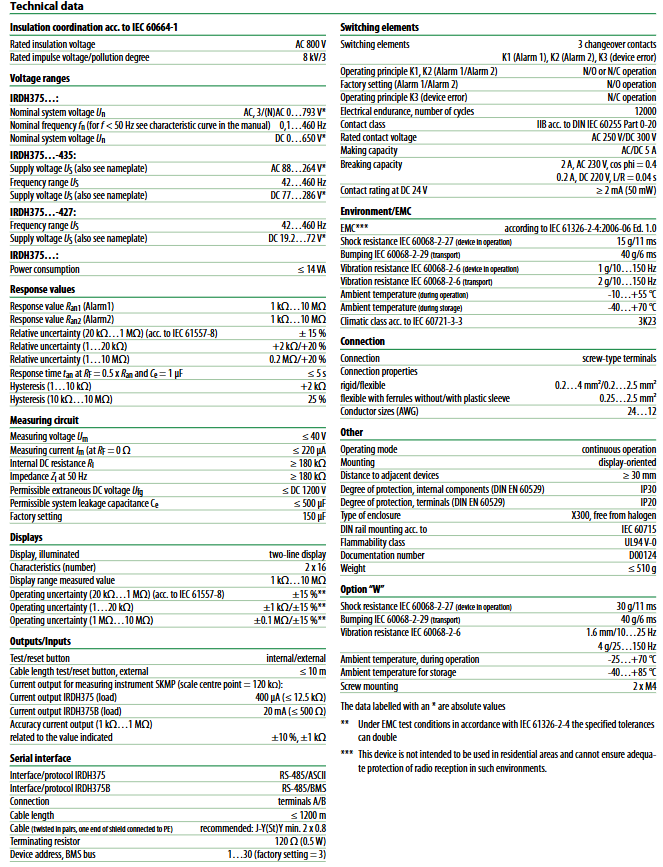

Basic adaptation systems: AC system, DC system, AC/DC hybrid main circuit

Special adaptation system: AC/DC main circuit with direct connection to DC components (such as rectifiers, converters, thyristor controlled DC drivers); UPS system, battery system; Phase controlled heater; Installation scenarios for equipment with switch mode power supply; High leakage capacitance IT system; Coupling IT systems

(2) Voltage parameter specifications

Rated monitoring voltage: AC/AC-DC 0... 793V, DC 0... 650V

Extended monitoring voltage: By combining with a dedicated coupling device, it can be extended to higher voltage levels such as DC 0... 1760V, 3/(N)/AC 0... 7200V (50... 400Hz), etc

Power supply voltage requirements:

AC power supply: 88... 264V (frequency 42... 460Hz)

DC power supply: 77... 286V or 19.2... 72V (please refer to the equipment nameplate for details)

Power protection: requires power supply through a 6A fuse; Mandatory requirement to use 5A fuses for UL and CSA application scenarios

Core technology and functional characteristics

(1) Measurement technology

Adopting the patented AMPPlus measurement method, designed specifically for modern power supply systems, it can accurately respond to complex scenarios containing a large number of directly connected DC components and high system leakage capacitors, effectively solving the problem of inaccurate monitoring by traditional measurement methods in such scenarios, and ensuring the stability and reliability of insulation resistance monitoring.

(2) Basic functions

Insulation monitoring core: Real time monitoring system insulation resistance, supporting two independent adjustable response values (1k Ω... 10M Ω), can set warning threshold and alarm threshold separately, achieving graded warning

Automatic adaptation capability: Without manual intervention, the device can automatically adapt to system leakage capacitance (maximum allowable value ≤ 500 μ F) and adapt to changes in system parameters under different operating conditions

Self monitoring and self testing:

Continuous self-monitoring: Real time inspection of the device's own working status, automatic triggering of system fault alarm in case of malfunction

Optional automatic self testing: supports manual self testing through the TEST button to verify device functionality and the connection status between the system and the earth

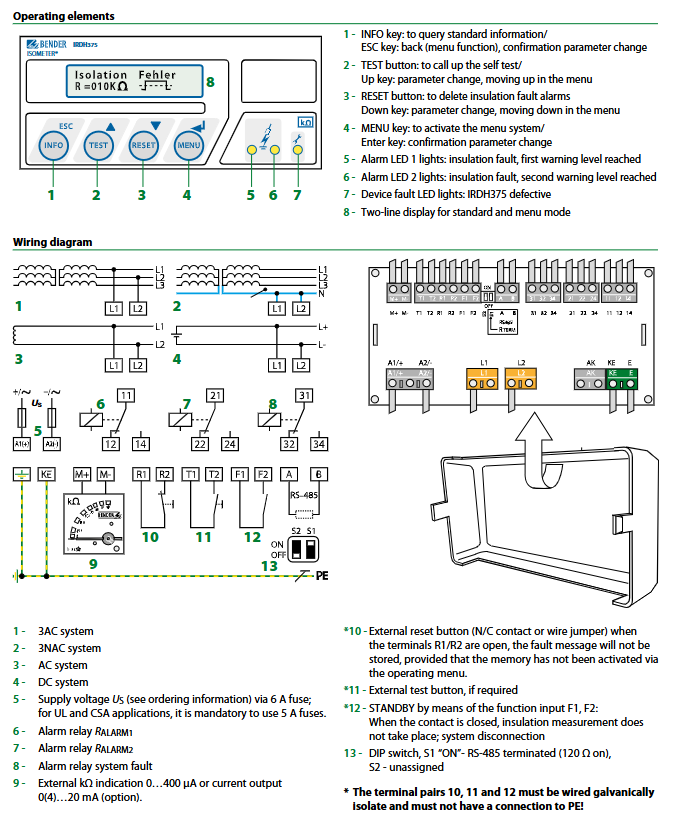

Display and operation:

Display configuration: Dual row backlit LCD display screen, supports switching between standard mode and menu mode, clearly displays insulation resistance value, device settings, fault information, etc

Operation buttons: equipped with four core buttons: INFO (query standard information), TEST (self-test), RESET (clear fault alarm), MENU (activate menu system), and support direction keys (up/down) and confirm key operation. Parameter configuration can be completed through panel buttons; Support external testing and reset buttons (cable length ≤ 10m)

Alarm function:

Alarm output: 2 independent alarm relays, both with passive conversion contacts, supporting N/O (normally open) or N/C (normally closed) operation modes; Additional configuration of system fault alarm relay (default N/C operation mode)

Alarm indication: 3 dedicated alarm LED lights, corresponding to "Level 1 Insulation Fault Warning", "Level 2 Insulation Fault Alarm", and "Equipment Self Fault", providing intuitive feedback on the alarm level

Fault storage: It can store fault information and clear it through the RESET button or external reset button (when terminals R1/R2 are disconnected and the storage function is not activated through the operation menu, the fault information is not stored)

Extension interface:

Communication interface: RS-485 interface (supports ASCII protocol), transmission distance ≤ 1200m (recommended to use J-Y (St) Y 2 × 0.8mm ² twisted pair, with one end of the shielding layer connected to PE), supports communication with external systems

External indicator interface: Reserve an external k Ω indicator interface (output 0... 400 μ A signal), which can be connected to external measuring instruments to display insulation resistance values

Terminal design: adopting plug-in terminals, convenient wiring, and terminal protection level up to IP30

Other auxiliary functions:

INFO button: Press to query additional information such as system leakage capacitance, current device settings, etc

Standby function: Controlled through function input ports F1 and F2, the device enters standby mode when the contacts are closed, pausing insulation measurement and achieving system disconnection control

DIP switch configuration: When the S1 switch is in the "ON" state, the RS-485 interface enables a 120 Ω terminal resistor; S2 switch has not yet been assigned a function

(3) Advanced features of IRDH375B (added compared to the base model)

Historical record storage: Built in historical memory with real-time clock, which can record all alarm information and attach date and time stamps for easy fault tracing and analysis

Enhanced Communication Capability: Equipped with an electrically isolated RS-485 interface, supporting BMS protocol, capable of stable communication with other Bender devices, and adaptable to centralized control scenarios such as building management systems

Coupling system adaptation: Built in insulation monitoring device disconnect relay, supports multiple IRDH375B devices to work together in the coupling IT system, and ensures that only one device is active at any time by controlling input ports F1/F2 to avoid monitoring conflicts

Analog output: Added 0 (4)... 20mA current output, which can be used for external data acquisition devices to achieve remote transmission and recording of insulation resistance data

Key performance parameters

Specific parameter specifications for performance categories

When the insulation resistance R_F=0.5 x the set response value R_an and the system leakage capacitance C_e=1 μ F, the response time is ≤ 5s

Measurement accuracy 1k Ω... 1M Ω Range: ± 15% ± 1k Ω; 1k Ω... 10M Ω Range: ± 15% ± 0.1M Ω (compliant with IEC 61557-8 standard)

Electrical durability contact category 12000 IIB (compliant with DIN IEC 60255 Part 0-20); Rated contact voltage AC 250V/DC 300V

Contact capacity AC/DC 5A; 2A at AC 230V, cos φ=0.4; 0.2A at DC 220V, L/R=0.04s; minimum control current ≥ 2mA (50mW)

Environmental adaptability working temperature: -10...+55 ℃ (regular model), -25...+70 ℃ (Option-W model); Storage temperature: -40...+70 ℃ (regular version), -40...+85 ℃ (Option-W version); Climate grade: IEC 60721-3-3 3K23

Anti interference and mechanical performance electromagnetic compatibility (EMC): compliant with IEC 61326-2-4:2006-06 Ed.1.0 standard; Impact resistance: IEC 60068-2-27 (15g/11ms); Anti collision (transportation): IEC 60068-2-29 (40g/6ms); Vibration resistance: IEC 60068-2-6 (1g/10... 150Hz, transportation scenario 2g/10... 150Hz); Option-W enhances impact resistance (30g/11ms) and vibration resistance (1.6mm/10-25Hz, 4g/25... 150Hz) performance

Mechanical specification panel opening size: 138 × 68mm; installation method: DIN rail installation (in accordance with IEC 60715 standard) or screw installation (2 × M4); Shell type: X300 type, halogen-free material; Protection level: IP20 for equipment casing; Weight ≤ 510g; distance between adjacent equipment installations ≥ 30mm

Wiring specification terminal type: spiral terminal; Conductor adaptation: rigid conductor 0.2... 4mm ², flexible conductor (with/without plastic sleeve) 0.2... 2.5mm ²; Suitable for AWG wire gauge: 24... 12; Terminal pairs 10, 11, and 12 must be electrically isolated and must not be connected to PE

Operation and Display Instructions

(1) Operation button function

Core functions of buttons/operating components

INFO key to query standard information; Cooperate with menu operations to achieve function switching

Return to the previous level in ESC menu mode; Confirm parameter changes

Test button to start device self-test; As an up arrow key in menu mode, it is used for parameter changes and menu navigation

The RESET button clears the insulation fault alarm record; As the down arrow key in menu mode, it is used for parameter changes and menu navigation

MENU key activates the menu system; As a confirmation key in menu mode, confirm parameter changes

Alarm LED 1 lights up to indicate insulation fault, reaching the first level warning threshold

Alarm LED 2 lights up to indicate insulation fault, reaching the second level alarm threshold

Device fault LED lights up to indicate a device malfunction (IRDH375 malfunction)

Dual row display screen standard mode displays insulation resistance value and fault information; Menu mode displays parameter configuration interface

(2) Parameter configuration method

Support two parameter configuration methods: one is to operate through the dual row LCD display screen on the device panel in conjunction with functional buttons; The second is to connect to the external control system through the RS-485 interface for remote configuration (in accordance with the corresponding communication protocol). During the configuration process, changes can be confirmed through the ESC key or Enter key, and the operation logic is clear and easy to understand.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923