K-WANG

BENDER IRDH575 Insulation Monitoring Equipment (IT System)

BENDER IRDH575 Insulation Monitoring Equipment (IT System)

Product Overview

(1) Product positioning and core applications

IRDH575 is an industrial grade insulation monitoring and fault location control integrated equipment launched by BENDER in Germany. It is designed specifically for ungrounded (IT) systems and is used to monitor the ground insulation resistance of 3 (N) AC, AC/DC hybrid, and pure DC systems in real time, identify the risk of grounding faults in advance, and can be expanded into an accurate fault location system. It is suitable for industrial scenarios with sensitive loads such as frequency converters, thyristor controlled DC drives, PLCs, etc., such as factory power distribution systems, automated production lines, new energy equipment, etc. Through the dual functions of "monitoring and warning+precise positioning", it ensures the electrical safety and continuous operation of IT systems, avoiding equipment damage or production interruption caused by grounding faults.

(2) Core Features and Compliance Standards

1. Core Features

Strong universality: It has a wide voltage range of adaptation (AC/DC 20... 575V low voltage type, 340... 760V high voltage type) and is compatible with multiple types of IT systems.

Accurate monitoring: The insulation resistance measurement range is 1k Ω... 10M Ω, supporting two-level alarm thresholds to distinguish between "potential risks" and "serious faults" in advance.

Positioning Expansion: Paired with EDS4 series positioning devices, it can cover up to 1080 circuits and accurately locate fault branches and sources.

Comprehensive functionality: It has multiple functions such as data storage, bidirectional communication, self-monitoring, and external device expansion, and is suitable for industrial centralized monitoring needs.

2. Compliance and Certification

Following standards: DIN EN 61557-8/9(VDE 0413-8/9)、IEC 61557-8/9、IEC 61326-2-4、ASTM F1669M-96(2007)、ASTM F1207M-96(2007)、DIN EN 60664-1/3(VDE 0110-1) Wait.

Certification qualifications: CE, UL/US LISTED certification, the shell adopts halogen-free design, and the flame retardant level reaches UL94 V-0, which meets environmental and safety requirements.

Core functions and operational features

(1) Insulation monitoring function

Core measurement mechanism

Measurement principle: Using the AMP measurement method, a weak test signal (measured voltage ≤ 40V, measured current ≤ 220 µ A) is injected into the system through a built-in measurement circuit to monitor the insulation resistance between the system conductor and ground. The measurement results are not affected by the system load current and rated voltage, and have strong stability.

Measurement range: 1k Ω... 10M Ω, covering the entire scene from low resistance faults (close to short circuits) to high resistance faults (slight insulation damage), and can identify faults in advance before leakage current occurs.

Measurement accuracy: The range error of 10k Ω... 10M Ω is 0%...+20%, and the range error of 1k Ω... 10k Ω is+2k Ω. The measurement data is reliable and provides accurate basis for fault diagnosis.

Hierarchical alarm mechanism

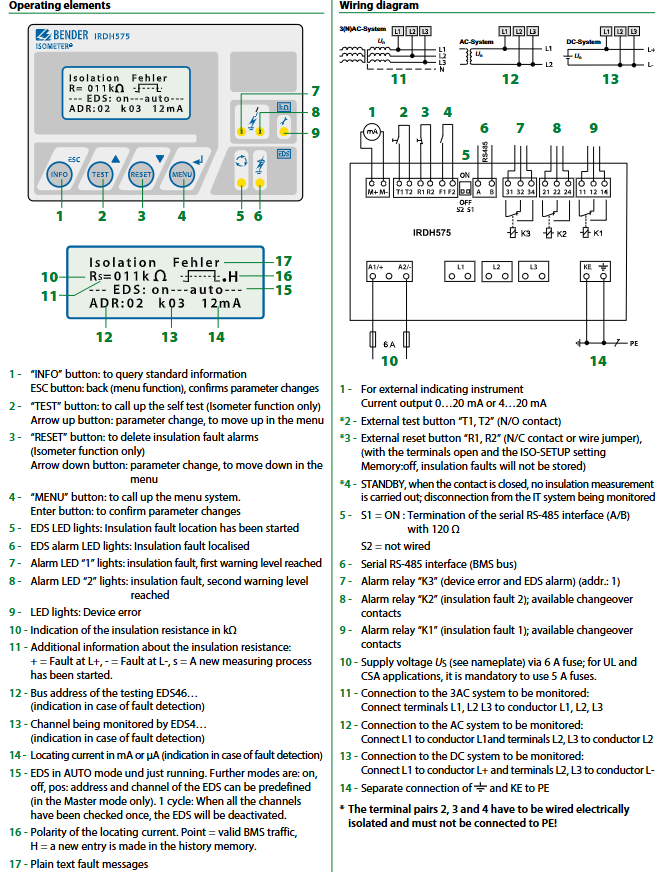

Alarm output: 3 switch contacts (SPDT), corresponding to first level alarm (K1, warning), second level alarm (K2, main alarm), equipment failure/EDS alarm (K3), supporting N/O (normally open) or N/C (normally closed) operation mode switching, factory default K1/K2 is N/O, K3 is N/C.

Alarm mode: Supports self-locking mode (manual reset after fault clearance) and non self-locking mode (automatic reset after fault clearance), which can be switched through menu settings and adapted to different fault handling processes.

Status indication: Alarm LED1 (first level alarm), Alarm LED2 (second level alarm), and equipment fault LED correspond to different alarm levels, providing intuitive feedback on the severity of the fault for quick on-site identification.

Self monitoring and testing

Self monitoring: Continuously monitor the grounding connection, line connection, and internal circuit status of the equipment itself. In case of abnormalities, trigger the K3 relay action and light up the equipment fault LED to avoid missed reports due to equipment failure.

Testing function: Supports internal/external testing buttons (N/O contacts), long press the TEST button to activate self-test, verify whether the alarm circuit, display system, and connection to the system/ground are normal, and ensure reliable device functionality.

Reset function: Internal/external reset button (N/C contact or jumper), short press the RESET button to clear the alarm memory. When the terminal is open and ISO-SETUP is set to Memory: off, insulation faults are not stored.

(2) Ground fault location function

System expansion configuration

Core components: IRDH575 host+EDS460 (main circuit positioning device)/EDS461 (control circuit positioning device)+dedicated current transformer (W series adapted to main circuit, 8000 series adapted to control circuit), optional EDS3090/EDS3091 portable positioning system.

Scalability: Supports up to 90 EDS4 series devices for interconnection, with each EDS device capable of monitoring 12 circuits, covering a total of 1080 circuits, and adapting to the fault location needs of large industrial distribution systems.

Positioning workflow

Trigger method: After IRDH575 detects an insulation fault, it automatically starts the positioning process, or can be manually started through the menu, flexibly adapting to different on-site requirements.

Signal generation: IRDH575 generates pulse positioning current, the amplitude of which depends on the system voltage and the degree of insulation fault. In case of low resistance fault, the positioning current is automatically limited, and the current limit value can be set through the menu (maximum 50mA). The pulse period is 2s and the interval is 4s to avoid affecting the normal operation of the system.

Fault identification: The positioning current pulse starts from the host through live parts, travels along the shortest path to the fault point, and then returns to the host through the insulation fault point and PE line. The current transformer on the fault path collects the pulse signal, which is evaluated by EDS equipment.

The results show that when the positioning current exceeds the response value of the EDS device, the EDS local alarm LED lights up, indicating the faulty sub circuit. At the same time, the IRDH575 LCD synchronously displays the bus address, monitoring channel, and positioning current intensity (mA/µ A) of the faulty EDS device, achieving accurate fault positioning.

Portable troubleshooting: Optional EDS3090/EDS3091 portable positioning system can track pulse signals to the source of faults, suitable for complex wiring and concealed fault troubleshooting scenarios.

PLC control circuit adaptation

Due to the sensitivity of PLC input signals, EDS461 equipment is required for control circuit positioning, and the positioning current of IRDH575 should be set to a maximum of 2.5mA or 1mA to avoid interfering with the normal operation of the PLC.

(3) Data storage and communication functions

Data recording and querying

Storage capacity: Non volatile memory can store 99 alarm messages with date and timestamp, including fault type, insulation resistance value, occurrence time, EDS device address, etc. Data will not be lost after power failure, making it easy to trace and analyze faults.

Information query: Pressing the INFO key can quickly query system leakage capacitance, device parameter settings, alarm history, and other information without entering deep menus, making operation convenient.

communication interface

RS-485 interface (BMS protocol): Supports bidirectional data communication between devices, with a maximum cable length of 1200m. It is recommended to use shielded cable J-Y (ST) Y 2 × 0.6mm ² (single ended PE for shielding layer), equipped with a 120 Ω terminal resistor (controlled by micro switch S1 to enable/disable), to reduce signal attenuation and electromagnetic interference.

Protocol extension: Can connect to Bendel protocol converters, adapt to industrial protocols such as Ethernet, MODBUS, PROFIBUS, etc., and achieve interconnection with upper control systems such as PLC and DCS.

Analog output: 0/4... 20mA optional, load ≤ 500 Ω, can convert insulation resistance signal into standard analog quantity, connect to external instruments or centralized monitoring system, achieve remote real-time monitoring of insulation status.

(4) Operation and display functions

display system

Backlit LCD screen: 4 × 16 character pure text display, character height 5mm, clear display, supports multilingual switching, real-time display of insulation resistance value (k Ω), system status, alarm information, EDS equipment status, etc.

Auxiliary display: "s" indicates that a new measurement is in progress, "+" indicates a fault on the L+side, and "-" indicates a fault on the L - side; EDS mode display (AUTO/ON/OFF/pos/1 cycle), POS mode can preset EDS address and channel (host mode only), EDS will automatically stop after detecting all channels in 1 cycle mode; Position current polarity indication (Point=active BMS communication, H=new historical record).

Operation buttons

Function keys: INFO (information query), MENU (menu call), ESC (return/confirm parameter modification), TEST (self-test), RESET (alarm reset).

Navigation keys: up/down arrow keys (menu scrolling, parameter adjustment), Enter key (confirm parameter modification).

Operation logic: Clear menu hierarchy, intuitive parameter settings, password protection support to prevent unauthorized personnel from tampering with settings.

Detailed technical parameters

(1) Electrical parameters

Category specific specifications

Monitoring system voltage low voltage type (B1 series): AC 20... 575V (3 (N) AC/single-phase, 50... 460Hz), DC 20... 575V

High voltage type (B2 series): AC 340... 760V (3 (N) AC/single-phase, 50... 460Hz), DC 340... 575V

Supply voltage AC 88... 264V (50... 460Hz), DC 77... 286V; UL/CSA applications mandate the use of 5A fuses, while 6A fuses are recommended for other scenarios; Two fuses are required for IT system power supply

Allow external DC voltage B1 series ≤ 810V, B2 series ≤ 1060V

Allow system leakage capacitance ≤ 150 (500) µ F

Relay parameters: rated contact voltage AC 250V/DC 300V, connection capacity AC/DC 5A, breaking capacity 2 A(AC 230V,cosφ=0.4)、0.2A(DC 220V,L/R=0.04s), Electrical lifespan of 12000 cycles, contact current (DC 24V) ≥ 2mA (50mW), contact level IIB (DIN IEC 60255-23)

Analog output 0/4... 20mA, load ≤ 500 Ω

Power consumption ≤ 14 VA

(2) Environmental and mechanical parameters

Category specific specifications

Working environment temperature -10 ℃...+55 ℃ (cannot operate continuously in 50mA positioning mode); The short-term working temperature can reach -25 ℃...+70 ℃

Storage environment temperature -40 ℃...+85 ℃

Climate grade DIN IEC 60721-3-3 (3K5)

Impact resistance performance during operation: 15g/11ms (IEC 60068-2-27); During transportation: 40g/6ms (IEC 60068-2-29); Option-W model: 30g/11ms

Vibration resistance performance during operation: 1g/10... 150Hz (IEC 60068-2-6); During transportation: 2g/10... 150Hz (IEC 60068-2-6); Option-W model: 1.6mm/10... 25Hz, 4g/25... 150Hz

Protection level: Internal components IP30, terminals IP20, door mounted IP40, optional IP42 (equipped with panel seals)

Installation method: Panel installation, hole size 138 × 90mm, installation direction is display facing outward, installation distance ≥ 30mm; optional DIN rail adapter (Art. No. B98060010)

Wire terminal screw terminal, supporting rigid conductors 0.2... 4mm ², flexible conductors 0.2... 2.5mm ², flexible conductors with/without plastic collars 0.25... 2.5mm ², compatible with AWG 24... 12 specification conductors

Shell and weight halogen-free flame-retardant shell, weight ≤ 900g

System installation and typical configuration

(1) Installation points

Power supply configuration: The power supply circuit is connected in series with corresponding specifications of fuses (5A for UL/CSA, 6A for others). The IT system power supply must be equipped with two fuses to ensure equipment overcurrent protection.

Grounding requirements: The equipment grounding terminal (KE) should be reliably grounded, and the RS-485 cable shielding layer should be single ended with PE to reduce electromagnetic interference; Terminal pairs 2, 3, and 4 require electrical isolation wiring and must not be connected to PE.

Wiring specifications: Measurement circuits and power cables should be laid separately to avoid cross interference; The wiring between EDS equipment and current transformers must follow polarity requirements to ensure accurate signal acquisition.

Environmental requirements: The installation location should be well ventilated, away from heat sources and strong electromagnetic interference sources, and meet the working temperature (-10...+55 ℃) and protection level requirements; The Option-W model has stronger shock and vibration resistance and is suitable for harsh environments.

(2) Typical application configuration

1. Main circuit monitoring and positioning system (AC/DC 20... 575V)

Configuration components: IRDH575B1-435+EDS460+W series current transformer+6A fuse.

Applicable scenarios: Factory three-phase main distribution circuit, motor control circuit, etc. Each EDS460 monitors 12 main circuit branches and supports cascading expansion of multiple EDS460.

Wiring method: The L1/L2/L3 terminals of the 3AC system are respectively connected to the L1/L2/L3 terminals of the equipment, the N line is connected as needed, and the KE terminal of the equipment is connected to PE; EDS460 communicates with IRDH575 through the AB terminal, and the current transformer is installed on the main circuit branch line.

2. Control circuit monitoring and positioning system (AC 20... 265V/DC 20... 308V)

Configuration components: IRDH575B1-435+EDS461+8000 series current transformer+6A fuse+PLC.

Applicable scenarios: PLC control circuits, DC instrument circuits, and other sensitive load circuits. EDS461 is designed to meet the high sensitivity requirements of control circuits and avoid interference from positioning currents on loads.

Wiring method: The L+terminal of the DC system is connected to the L1 terminal of the device, the L - terminal is connected to the L2/L3 terminal, and the KE terminal of the device is connected to the PE terminal. EDS461 communicates with IRDH575, and the current transformer is installed on the PLC input and output circuit line, with a positioning current set to 1... 2.5mA.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923