K-WANG

BENDER WR70x175S (P)... WR200x500S (P) rectangular measuring current transformer

BENDER WR70x175S (P)... WR200x500S (P) rectangular measuring current transformer

Product Overview

(1) Product positioning and core applications

WR70x175S (P)... WR200x500S (P) is an industrial grade rectangular measuring current transformer developed by BENDER in Germany. It is designed for current signal conversion and precise acquisition, and is used in conjunction with residual current monitoring systems and insulation fault location systems to achieve current monitoring and fault tracing in industrial electrical circuits. It is suitable for AC/DC hybrid power supply scenarios and can convert high or positioning currents on the primary side into assessable standard signals on the secondary side, providing accurate data support for backend monitoring equipment. It is widely used in industrial scenarios such as factory distribution systems, busbar systems, IT systems (ungrounded systems), etc.

(2) Core Features and Compliance Standards

1. Core Features

Dual scenario adaptation: compatible with RCM/RCMS series residual current monitoring systems, converting AC current signals; It can also be paired with EDS series insulation fault location system (IT system) to collect the positioning current generated by PGH positioning current injector or IRDH series insulation monitoring instrument.

Series differentiation design: divided into the S series without integrated shielding and the SP series with integrated shielding. The SP series is designed specifically for busbar systems with load currents ≥ 500A, which can avoid false triggering of backend devices caused by high load currents or surge currents.

High reliability: Equipped with a built-in secondary side overvoltage protection diode, it has strong resistance to impact and vibration, and is suitable for harsh industrial environments.

Flexible installation: Supports installation in any direction, adapts wires to multiple specifications, and meets different on-site wiring needs.

2. Compliance and Certification

Following standards: DIN EN 60044-1 (General Technical Standard for Current Transformers), IEC 61869 (Power Transformer Standard), IEC 61869-2 (Insulation Coordination Standard), DIN IEC 60721-3-3 (Climate Rating Standard).

Safety level: The flame retardant rating of the shell reaches UL94 V-0, the internal component protection level is IP40, and the terminal protection level is IP20, effectively preventing solid foreign objects from entering and electrical safety risks.

Product classification and core parameters

(1) Product series and model differentiation

Series Core Features Applicable Scenarios Model Range

S series without integrated shielding, basic design for conventional industrial scenarios, circuits with load current<500A WR70x175S、WR115x305S、WR150x350S、WR200x500S

SP series with integrated shielding, strong anti-interference ability, busbar system, circuit with load current ≥ 500A, high interference environment WR70x175SP, WR115x305SP, WR150x350SP, WR200x500SP

(2) Key electrical parameters

Category specific specification remarks

Maximum system voltage (Um) AC 720 V suitable for medium and high voltage industrial distribution systems

Rated impulse withstand voltage (Uisol) 3 kV meets industrial insulation coordination requirements

Rated transformation ratio 600:1 Fixed transformation ratio to ensure signal conversion consistency

Rated load 180 Ω matching backend monitoring/positioning equipment input impedance

Rated primary current minimum ≥ 10 mA, maximum ≤ 10 A (100 A) to cover small signal acquisition and high current monitoring requirements

Rated nominal power of 50 mVA ensures sufficient signal transmission power

Rated frequency 50... 400 Hz, suitable for industrial scenarios of power frequency and intermediate frequency

Internal resistance of 5... 8 Ω reduces signal transmission loss

Secondary side overvoltage protection suppression diode P6KE6V8CP prevents overvoltage damage to backend equipment

Accuracy level 5 meets the requirements of industrial current measurement error

Rated continuous thermal current of 100 A, stable long-term operation without overheating risk

Rated short-time thermoelectric current 14 kA/1 s withstand short-time short-circuit current surge

Rated dynamic current of 35 kA/30 ms to resist instantaneous dynamic current surge

(3) Physical dimensions and weight

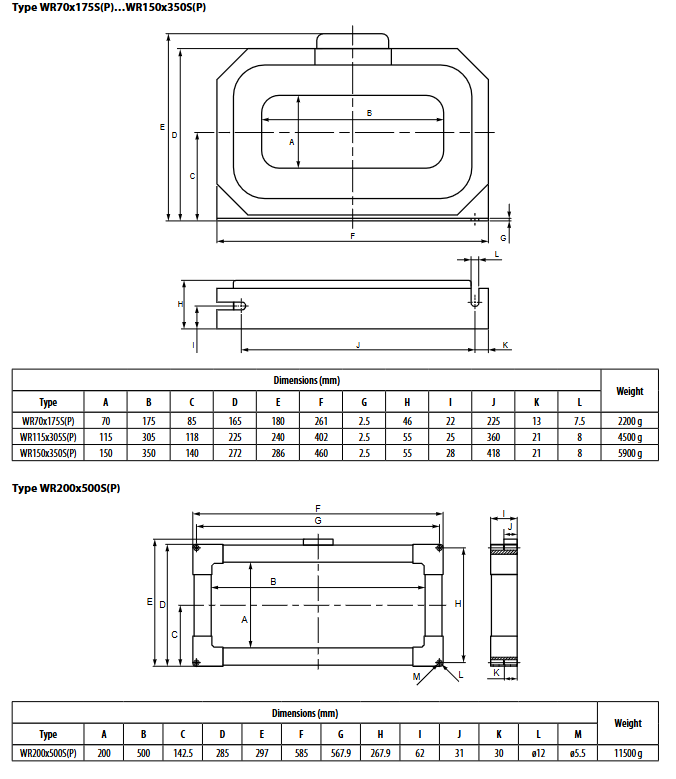

1. Size and weight of WR70x175S (P)~WR150x350S (P)

Model size (mm) Weight

A (internal width) B (internal height) C D E F G H I J K L

WR70x175S(P) 70 175 85 165 180 261 2.5 46 22 225 13 7.5 2200 g

WR115x305S(P) 115 305 118 225 240 402 2.5 55 25 360 21 8 4500 g

WR150x350S(P) 150 350 140 272 286 460 2.5 55 28 418 21 8 5900 g

2. WR200x500S (P) size and weight

Model size (mm) Weight

A (internal width) B (internal height) C D E F G H I J K L M

WR200x500S(P) 200 500 142.5 285 297 585 567.9 267.9 62 31 30 ø12 ø5.5 11500 g

Installation and wiring specifications

(1) Core installation requirements

Prohibited conductors to pass through:

It is strictly prohibited to pass shielded cables, PE conductors, and low resistance conductor circuits through transformers, otherwise interference signals may be introduced, leading to a decrease in measurement accuracy or misjudgment by backend equipment.

All current carrying wires must pass through the transformer completely without omission, ensuring comprehensive collection of current signals.

Wire threading direction and position:

The wire needs to be threaded in from the P1 (K end, yellow mark) side and out from the P2 (L end, gray mark) side. Incorrect direction can cause signal polarity reversal and affect data accuracy.

The wires need to be aligned with the center position of the transformer to avoid uneven magnetic field distribution caused by offset, further ensuring measurement accuracy.

Wire bending and spacing:

The bending of the primary side conductor must follow the minimum bending radius specified by the manufacturer, and the 90 ° bending distance must not be less than twice the height of the transformer to prevent insulation damage to the conductor and distortion of current distribution.

Installation and fixation:

Supports installation in any direction (horizontal, vertical, etc.), fixed on the installation surface with M5 screws to ensure a firm and secure installation without looseness, and to avoid vibration affecting performance during operation.

(2) Wiring and Connection Specifications

Conductor adaptation:

The terminal block is screw type and supports rigid conductors (0.2... 4mm ²), flexible conductors (0.2... 2.5mm ²), and flexible conductors with/without plastic collars (0.25... 2.5mm ²), compatible with AWG 24... 12 specification conductors.

Cable selection and distance:

Single core wire (≥ 0.75mm ²): maximum connection distance of 1m.

Twisted single core wire (≥ 0.75mm ²): maximum connection distance of 10m.

Shielded cable (≥ 0.6mm ²): maximum connection distance of 40m, recommended model J-Y (St) Y 2 × 0.6mm ², shielding layer needs to be connected to PE at one end to reduce electromagnetic interference.

Wiring precautions:

Before wiring, the power supply must be disconnected to ensure construction safety; Tighten the terminal screws after wiring to avoid signal distortion caused by poor contact.

Connected to backend devices (RCM/RCMS/EDS) through two-wire cables, S1 (k) and S2 (l) terminals correspond to device signal input interfaces.

Environmental adaptability and mechanical characteristics

(1) Environmental parameters

Category specific specifications

Working environment temperature -10 ℃...+50 ℃

Storage environment temperature -40 ℃...+70 ℃

Climate grade DIN IEC 60721-3-3 (3K22)

Impact resistance performance (in operation) 15 g/11 ms (IEC 60068-2-27)

Anti collision performance (during transportation) 40 g/6 ms (IEC 60068-2-29)

Vibration resistance performance (in operation) 1 g/10... 150 Hz (IEC 60068-2-6)

Vibration resistance performance (during transportation) 2 g/10... 150 Hz (IEC 60068-2-6)

(2) Mechanical characteristics

Shell material: flame retardant grade UL94 V-0, high temperature resistance, anti-aging, in line with industrial safety requirements.

Protection level: Internal components IP40 (preventing solid foreign objects with a diameter of ≥ 1mm from entering), terminals IP20 (preventing finger touch).

Operation mode: Continuous operation, uninterrupted collection of current signals, meeting the 24-hour uninterrupted production needs of industry.

Model specifications and ordering information

(1) Model and Order Number Correspondence Table

Model Internal dimensions (mm) Shielding characteristics Order number

WR70x175S 70 × 175 without B911738

WR115x305S 115 × 305 without B911739

WR150x350S 150 × 350 without B911740

WR200x500S 200 × 500 without B911763

WR70x175SP 70 × 175 integrated shielding B911790

WR115x305SP 115 × 305 integrated shielding B911791

WR150x350SP 150 × 350 integrated shielding B911792

WR200x500SP 200 × 500 integrated shielding B911793

(2) Selection suggestions

Selection based on load current: If the load current is ≥ 500A or applied to the busbar system, the SP series (with shielding) is preferred; For conventional load current scenarios, select the S series.

Select according to internal dimensions: Select the corresponding internal dimensions based on the number and thickness of the primary side conductors to ensure that the conductors can pass through the transformer smoothly and leave appropriate gaps.

Selection based on connection distance: When the connection distance exceeds 10m, shielded cables should be selected and matched with the wiring requirements of the corresponding transformer model.

Precautions and Maintenance Guidelines

(1) Precautions for use

It is strictly prohibited to dismantle the transformer casing or modify the internal circuit without authorization, otherwise it will damage the insulation performance and shielding structure, and lose the product warranty qualification.

Transformers need to be used in conjunction with compatible backend devices (RCM/RCMS/EDS) to avoid signal attenuation or equipment damage caused by load mismatch.

Installation and maintenance must be carried out by qualified electrical professionals, strictly following local electrical safety regulations.

(2) Key points of daily maintenance

Regular inspection: Check the installation and fixation of the transformer, whether the wiring terminals are loose, and whether the cable insulation layer is damaged every month. If any problems are found, they should be dealt with in a timely manner.

Environmental cleaning: Keep the surface of the transformer clean to avoid dust accumulation affecting heat dissipation or insulation performance.

Fault handling: If there is no signal input or signal abnormality in the backend equipment, it is necessary to sequentially check whether the cable connection, conductor direction, and transformer are damaged. If necessary, contact the manufacturer's technical support.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923