K-WANG

Kollmorgen SERVOSTAR 300 (S300) series digital servo drive

Kollmorgen SERVOSTAR 300 (S300) series digital servo drive

Product Overview and Model Code

Product Core Positioning

The S300 series is a digital servo drive launched by Kollmorgen for medium power high-precision motion control scenarios. The hardware version has been iterated to 04.20, supporting SFD3/HIPERFACE DSL single cable connection, integrating STO safety function, suitable for synchronous servo motors, asynchronous motors, and linear motors, and can expand bus and I/O capabilities through expansion cards. Its core advantages lie in dual voltage adaptation, multi feedback compatibility, and flexible expansion performance, and it is widely used in automation production lines, precision machine tools, multi axis collaborative equipment and other scenarios.

Model coding rules

The model consists of "series+current level+voltage type+function options+expansion card", and the core coding dimensions and example analysis are as follows:

Explanation of the meaning of the coding section and key codes

Series Identification Core Product Series S30361(3ARMS/110-230V)、S30601(6ARMS/208-480V)、S31061(10ARMS/110-230V)

Current level Continuous current specifications 03 (3ARMS), 06 (6ARMS), 10 (10ARMS)

Voltage type power supply input type 6 (110-230VAC), 0 (208-480VAC)

Function Options Core Function Configuration - NA (no extensions), - EC (built-in EtherCAT), - FN (built-in fan control)

Optional expansion modules OPT-PB3 (PROFIBUS), OPT-EC (EtherCAT), OPT-EI (I/O-14/08) for expansion cards

Core Technical Parameters

Power Supply and Current Parameters

Model Supply Voltage Continuous Current (ARMS) Peak Current (ARMS) Maximum DC Bus Voltage (VDC) Heat Loss (W)

S30361 110-230VAC 3 9 450 35

S30661 110-230VAC 6 15 450 60

S31061 110-230VAC 10 20 450 90

S30101 208-480VAC 1.5 4.5 900 40

S30301 208-480VAC 3 7.5 900 60

S30601 208-480VAC 6 12 900 90

Control Performance and Safety Parameters

Dynamic performance: current loop bandwidth of 250kHz, speed loop proportional gain of 0.1-100 ARMS/rad/s, position loop proportional gain of 0.1-100 Hz

Feedback resolution: Sin Cos encoder supports 1Vpp signal, EnDat2.2 supports 25 bit absolute resolution

Safety function: STO response time ≤ 1ms, PFHD 1.5 × 10 ⁻⁷ 1/h, MTBF 20 years

Braking circuit: Built in braking resistor (20-50W), supports external braking resistor expansion, braking threshold 200-840VDC

Installation and wiring specifications

Installation Requirements

Installation method: Vertically installed on a conductive grounding surface, the control cabinet needs good ventilation

Heat dissipation gap: top/bottom ≥ 40mm, side ≥ 75mm, high-power models require the installation of a fan

Mechanical dimensions: width 70mm, height 270-279mm, depth 171mm, weight approximately 2.6-2.7kg

Environmental restrictions: Working temperature 0-40 ℃ (with a capacity reduction of 2.5%/℃ for 40-55 ℃), humidity 10-85% (without condensation), altitude<1000m (with a capacity reduction of 1.5%/100m for 1000-2500m)

Core interface wiring

The manual provides detailed wiring definitions for 17 core interfaces, with the following key points:

Power wiring: X0 interface distinguishes 1/3 phase input, L1/L2/L3 is connected to the main power supply, and PE grounding must comply with IEC 60364 specifications

DC bus wiring: X8 interface supports parallel connection of multiple drivers (total current of 110-230V series ≤ 24A, 208-480V series ≤ 40A), requiring 2.5mm ² shielded cable

Motor wiring: X9 interface connects U/V/W three-phase, brake signal BRAKE+/BRAKE - supports 24VDC/1.5A brake control, motor cable>25m requires motor choke coil

Feedback wiring: X1 supports SFD3/HIPERFACE DSL single cable, X2 supports Resolver, X5 supports SSI/incremental encoder, feedback cable requires twisted pair shielding

STO wiring: X4 interface STO-ENABLE needs to be connected to a 24VDC safety signal. When disconnected, the motor can stop freely due to demagnetization, and mechanical braking needs to be used to ensure the safety of vertical loads

Parameter Configuration and Control Mode

Basic Configuration

Station address and baud rate: Set through the front panel buttons, CANopen defaults to a baud rate of 500kBaud and supports 10-1000kBaud adjustable

STO configuration: An external safety relay (compliant with SIL CL 2/PLd) is required, wiring should be kept away from power cables, and external wiring should be protected

Braking threshold: Set through DRIVE GUI software, default 200VDC (110VAC model), 400VDC (230VAC model), 720VDC (400VAC model)

Core parameter configuration

Parameter Category Key Parameter Function Description Value Range

Current loop Kp proportional gain 0.1-100 V/A

Speed loop Kp Speed loop proportional gain 0.1-100 ARMS/rad/s

Speed loop Ki Speed loop Integral gain 0-1000 Hz

Position loop Kpp Position loop proportional gain 0.1-100 Hz

Electronic Gear GearIn/GearOut Electronic Gear Ratio 1-65535

Current limit I RMS/I Peak Continuous/Peak current limit 0-100% rated value

Feedback configuration FBTYPE feedback type selection 0 (Resolver), 35 (HIPERFACE DSL), etc

Control mode configuration

Torque mode: Supports ± 10V analog commands, with a resolution of 14 bits, suitable for torque closed-loop control scenarios

Speed mode: Supports analog commands, pulse commands, or bus commands, with a speed loop update cycle of 62.5 μ s and a stable speed accuracy of ± 0.1%

Position mode: Supports step direction (1.5MHz), electronic gear, multi axis master-slave cooperation, and position error window can be set

Electronic gear: supports external encoder as the main shaft, follows proportionally from the shaft, with a gear ratio accuracy of 1/65535

Troubleshooting and Maintenance

Core fault codes and troubleshooting

Fault codes, fault types, common causes, troubleshooting methods

F01 heat sink overheating environment temperature is too high, and the heat dissipation gap is insufficient. Clean the heat dissipation channel, reduce the load, and check the fan (- FN model)

F02 bus overvoltage brake resistor failure, rapid deceleration check brake resistor wiring, extend deceleration time, install external brake resistor

F04 feedback fault feedback cable breakage, wiring error check feedback wiring, measure feedback power supply, replace cable

F06 motor overheating, motor overload, thermal sensor failure to reduce load, check motor thermal sensor wiring, measure winding temperature

F27 STO fault: Both STO-ENABLE and ENABLE effectively adjust the control logic to ensure that the motor has stopped before STO activation

Key points of daily maintenance

Regular inspection: cleaning of heat dissipation channels, fastening of wiring terminals, integrity of feedback cable shielding, recommended every 6 months

Capacitor reformation: When stored for more than 1 year without use, 230VAC single-phase electricity needs to be added for 30 minutes to activate the capacitor

Parameter backup: Backup parameters (. cfg files) through DRIVE GUI software to avoid configuration loss due to misoperation

Expansion card maintenance: When inserting or removing expansion cards, power must be turned off. During installation, ensure that the guide rail is inserted into place and the screws are tightened

Expansion Cards and Accessories

Core Expansion Card

Expansion card type, model, core function, interface type

I/O Expansion OPT-EI 14 channel digital input, 8 channel digital output MiniCombicon

PROFIBUS OPT-PB3 supports PROFIBUS DP protocol SubD 9-pin

EtherCAT OPT-EC supports EtherCAT bus and RJ45 ring network topology

SynqNet OPT-SN supports SynqNet network and multi axis synchronous RJ45

Dual CAN OPT-2CAN separates RS232 and CAN interfaces, supports bus terminal SubD 9-pin x 3

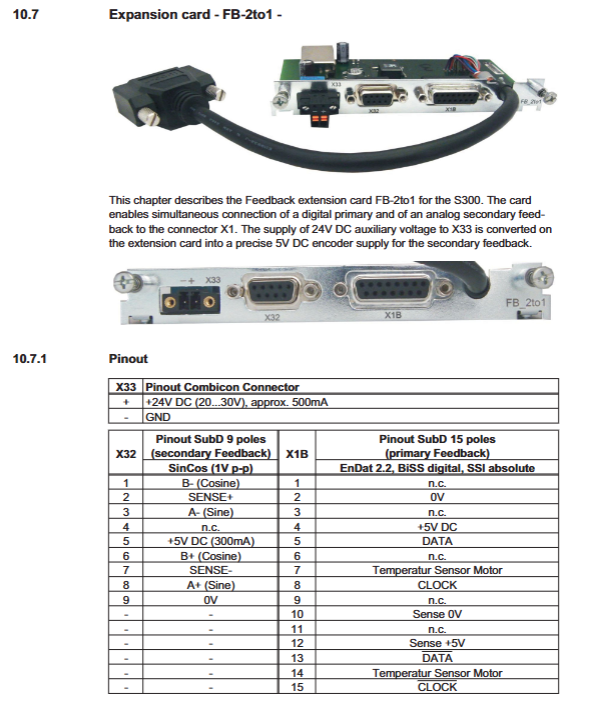

Feedback extension FB-2to1 supports both digital main feedback and analog sub feedback SubD 9/15 pins simultaneously

Special Accessories

Braking resistor: Supports 20-1000W external braking resistors, recommended resistance values of 66 Ω (110-230V) and 91 Ω (208-480V)

Cable: Dedicated motor/feedback cable (CCJ5/WCJ5 series), supports single cable connection, protection level IP67

Connector: X0/X8/X9 dedicated connector, suitable for current carrying requirements of different voltage levels

Software tool: DRIVE GUI. EXE (Windows compatible), supports parameter configuration, oscilloscope monitoring, and fault diagnosis

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923