K-WANG

Kollmorgen Servo System Product Guide

Kollmorgen Servo System Product Guide

Brand and Core Positioning

Kollmorgen, as a core brand focused on motion control under the Danaher Group (parent company of $14B), has the core mission of "precise control of speed, accuracy, and position", providing OEM engineers with complete motion solutions from standard products to fully customized solutions. The brand advantage is reflected in three major aspects:

Full industry chain capability: self-developed and self-produced servo drives, motors, gearboxes and other full category components, supporting seamless integration;

Global services: We have production bases and distributors in North America, Europe, the Middle East, and Asia, providing fast delivery and localized support;

Compliance and reliability: The product has passed UL, CE, and RoHS certifications, with protection levels covering IP44-IP67, suitable for harsh industrial environments and high-precision scenarios such as medical and semiconductor.

Detailed explanation of the six core product lines

Servo Drive (AKD Series)

As the core control unit of the entire series, the AKD series is based on Ethernet interconnection, providing flexible programmability and multi protocol support. The core parameters are as follows:

Model Specification Supply Voltage Continuous Current Peak Current Control Mode Support Protocol

AKD-00306 120/240VAC 3ARMS 9ARMS torque/speed/position EtherCAT, SynqNet, etc

AKD-02407 240/480VAC 24ARMS 48ARMS Multi axis Synchronous Modbus/TCP, PROFINET

AKD-M01206 120/240VAC 12ARMS 30ARMS Embedded PLC CANopen, EtherNet/IP

Core features:

Performance: 800Hz speed loop bandwidth, 27 bit high-resolution feedback, automatic tuning function adapted to 1000:1 inertia ratio;

Scalability: Supports multiple feedbacks such as SFD, EnDat2.2, BiSS, etc., and I/O can be expanded to 31 digital inputs/12 outputs;

Compact design: Width 57-105mm, industry-leading power density, supports DC Bus sharing.

Servo Motor (AKM Series)

A core execution unit seamlessly compatible with AKD drivers, covering 8 frame numbers (40-260mm), with the following core parameters:

Frame number, continuous torque range, peak torque range, rated speed feedback option, protection level

AKM1(40mm) 0.16-0.41Nm 0.61-1.46Nm 3000-8000RPM SFD、 Encoder and rotary transformer IP65 optional

AKM5 (115mm) 4.79-13.5Nm 10.6-31.3Nm 1200-6000RPM single/multi turn absolute encoder IP67 optional

AKM7(180mm) 29.5-46.8Nm 56.0-95.3Nm 1200-3000RPM EnDat2.2、BiSS IP65

Core features:

High torque density: 47% increase in shaft power compared to traditional motors of the same size;

Flexible configuration: 28 frame stack combinations, 117 standard windings, supporting customized shafts, actuators, and connectors;

Precise control: Step accuracy ± 0.333 arc minutes, low cogging effect ensures smooth operation at low speeds.

Direct Drive Motor (DDR/CDDR Series)

Eliminating mechanical transmission components (gears, belts) to achieve direct load drive, the core is divided into two categories:

Type represents model, continuous torque peak torque, repetitive torque accuracy, and adaptation scenario

Cartridge type (CDDR) C064A 4.57Nm 12.3Nm 0.7 arc second printing and conveying equipment

Cartridge type (CDDR) C133C 499Nm 1070Nm 0.7 arc second heavy-duty machine tool

Shell type (DDR) D061 5.3Nm 16.9Nm<1 arc second medical equipment, indexing table

Shell type (DDR) D143 339Nm 1340Nm<1 arc second high-precision positioning platform

Core advantages: No backlash, high bandwidth (doubled throughput), zero maintenance, and 20dB lower noise than traditional transmission.

Linear Positioning System

Covering the full scenario requirements of "thrust precision stroke", the three core sub products are:

Electric cylinder (N2/EC series)

N2 series: small size, maximum thrust of 600lb (2670N), speed of 30in/sec (0.76m/s), in compliance with NFPA standards;

EC series: IP54 protection (IP65 optional), EC5 model maximum thrust 5620lb (25000N), speed 52.5in/sec (1.33m/s), ISO6431 metric design.

Rod free actuator (R series)

Model: R2A (2 × 2in section), R3 (2.5 × 2.8in), R4 (3.6 × 4.25in);

Core parameters: maximum travel of 108 in (2700mm), belt drive speed of 120 in/sec, ball screw thrust of 700lb.

Precision worktable (DS4/DS6 series)

DS4: stroke 50-600mm, repeatability ± 1.3 μ m (precision level), load 170kg;

DS6: Travel 100-2000mm, ball screw lead 5/10/25mm, acceleration 20m/s ².

Planetary Gearbox (Micron) ™ Series)

Adopting helical crown gear technology, core series and parameters:

Series Type Peak Torque Gear Ratio Range Backlash Efficiency

NEMA True ™ In line 170-1600lb in 3-100:1 8-15 arc minutes 88-93%

EverTRUE ™ Straight 4090-26280lb in 4-100:1 4-5 arc minutes 90-95%

DuraTRUE ™ Right angle 460-7380lb in 5-500:1 8-9 arc minutes 88-93%

Core advantage: RediMount ™ The system achieves error free installation, with a high contact ratio (3.3:1) to ensure silent operation, and is compatible with AKM motors and stepper motors.

Step by Step Products

High cost-effective and precise control solution, with core components including motors and drivers:

Stepper motor: CT series (NEMA17/23/34), N/K series (NEMA34/42), enhanced K series with a torque increase of 25-40% and a maximum holding torque of 5650oz in (39.9Nm);

P7000 driver: Supports 20-75VDC/120/240VAC power supply, continuous current 2.5-5ARMS, with automatic tuning, anti resonance control, and dynamic smoothing functions.

Key Technologies and Customized Services

Core Technical Characteristics

Control performance: 800Hz speed loop bandwidth, 3-5kHz current loop bandwidth, 27 bit feedback resolution ensures repeat positioning accuracy of ± 0.0005in;

Connection and programming: Supports mainstream industrial protocols such as EtherCAT and SynqNet, built-in IEC61131-3 soft PLC, supports BASIC programming and Pipe Network ™ Graphic motion programming;

Environmental adaptability: Working temperature -30~70 ℃, some products support customization for vacuum, radiation and explosion protection.

Customized Services

Kollmorgen offers three levels of customized solutions to meet different needs:

Standard product modification: shaft modification, winding customization, connector replacement, protection upgrade (IP67);

Semi customized design: optimizing parameters (torque, speed, size) based on existing product lines;

Full custom development: Collaborative design of the entire process from concept to mass production, supporting rapid prototyping (weeks of delivery).

Auxiliary Resources and Support

Selection Tools

Motioneering ® Application Engine: Windows compatible motor sizing software, supporting multi axis load analysis, linear/rotary mechanism modeling, and generating PDF selection reports;

Support mechanism: More than 6 types of mechanisms such as screw, gear rack, conveyor belt, and various motion curves such as triangular wave/trapezoidal wave.

Accessories

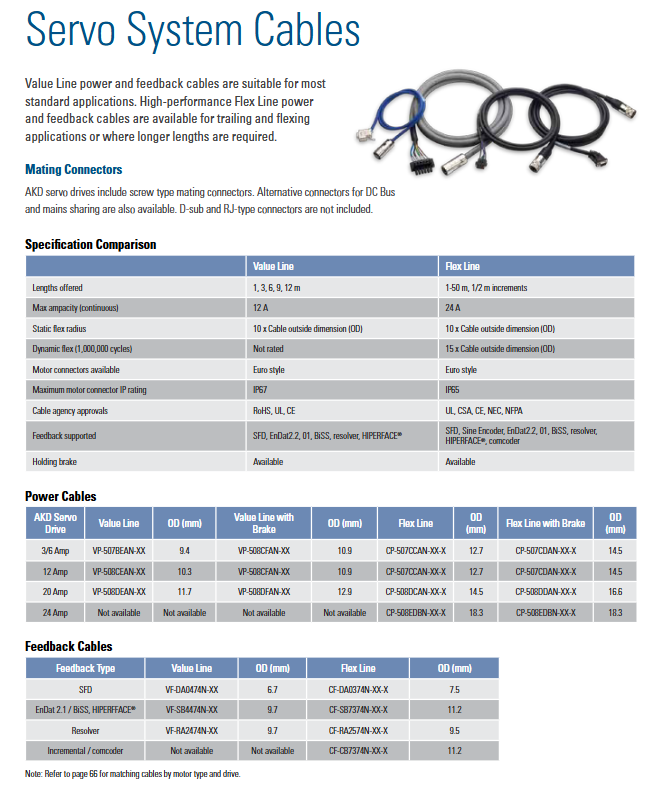

Cable: Value Line (1-12m), Flex Line (1-50m), supporting feedback types such as SFD and EnDat2.2

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923