K-WANG

Danaher Motion S200 series high-performance brushless servo drive

Danaher Motion S200 series high-performance brushless servo drive

Product Overview and Model Code

Product Core Positioning

The S200 series is a high-performance compact brushless servo drive launched by Danaher Motion. It is divided into basic models (- VTS) and SynqNet network models (- SRS/- SDS), focusing on "small size and high performance". With an 800Hz speed loop bandwidth, 3-5 kHz current loop bandwidth, and 24 bit high-resolution feedback, it achieves smooth motion and fast start stop, suitable for semiconductor manufacturing, electronic assembly, medical and other scenarios that require high precision and response speed. The product was first released in 2004 and updated to Rev. C version in 2008, adding high-power models S21260 (12/30ARMS) and S22460 (24/48ARMS). Products produced after 2007 comply with the RoHS directive.

Model coding rules

The model consists of "series+current level+voltage type+functional options+interface type", and the core coding dimensions and example analysis are as follows:

Explanation of the meaning of the coding section and key codes

Series Identification Core Product Series S20260(AC,4.5ARMS)、S20360(AC,9ARMS)、S20660(AC,18ARMS)、S20330(DC,9ARMS)

Current level peak current specifications 02 (4.5ARMS), 03 (9ARMS), 06 (18ARMS), 12 (30ARMS), 24 (48ARMS)

Voltage type power supply input type 3 (DC 20-90VDC), 5 (AC 120V double voltage/240V single-phase), 6 (AC 120/240VAC)

Function Options Core Function Configuration - VTS (Basic), - SRS (SynqNet+RJ45 Interface), - SDS (SynqNet+Micro-D Interface)

Core Technical Parameters

Power Supply and Current Parameters

Model Series Power Supply Type Peak Current (ARMS) Continuous Current (ARMS) Peak Power (VA) Continuous Power (W)

S20260 AC 120/240V 4.5 1.5 1400 (1 phase)/1500 (3 phases) 500 (1 phase)/600 (3 phases)

S20360 AC 120/240V 9 3 2600 (1 phase)/3000 (3 phases) 900 (1 phase)/1100 (3 phases)

S20660 AC 120/240V 18 6 5000 (1 phase)/6000 (3 phases) 1500 (1 phase)/2000 (3 phases)

S20330 DC 20-90VDC 9 3 750 250

S20630 DC 20-90VDC 18 6 1500 500

S21260 AC 240V 30 12 8000 (1 phase)/10000 (3 phases) 2500 (1 phase)/4000 (3 phases)

S22460 AC 240V 3-phase 48 24 16000 8000

Control Performance and Feedback Parameters

Control mode: Supports three modes: torque/current, speed, and position. The position mode supports step direction and AquadB command input

Dynamic performance: The maximum stable bandwidth of the speed loop is 800Hz, the current loop width is 3-5kHz, and the position command resolution is<0.001rpm (analog)/0.558rpm (serial)

Feedback resolution: SFD feedback 0.0013 arc minutes per revolution, repeat positioning accuracy<± 0.04 arc minutes RMS

Instruction interface: Analog instruction ± 12.5V, maximum step frequency 1.5MHz, PWM instruction 0.25-250kHz

Protection functions: over temperature, over voltage, under voltage, over current, short circuit, I ² T thermal protection, feedback fault protection

Installation and wiring specifications

Installation Requirements

Installation method: Vertically installed on a conductive grounding surface, remove the paint from the installation area to ensure good grounding

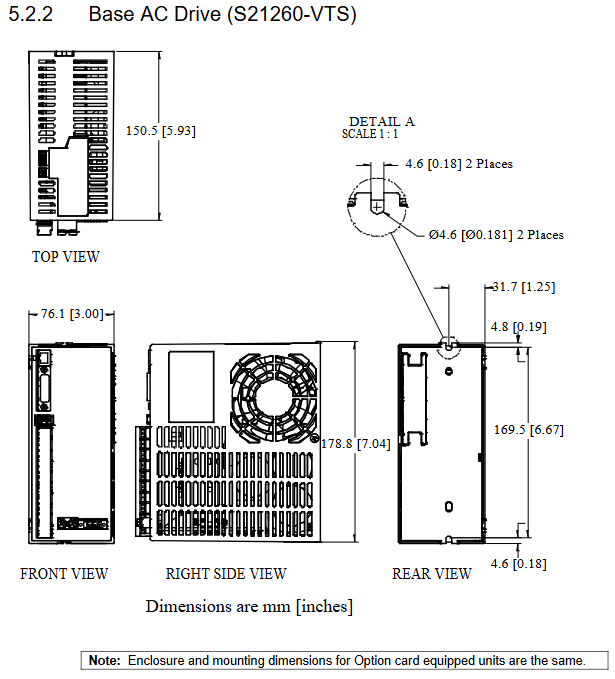

Heat dissipation gap: minimum 12.7mm at the top/bottom (19mm for S21260/S22460), minimum 12.7mm at the sides (19mm for S21260/S22460)

Mechanical dimensions: width 28.7-96.4mm, height 152.4-213mm, depth 100.8-192.4mm, weight 0.4-2.63kg

Environmental restrictions: Operating temperature 0-40 ℃ (50 ℃ requires capacity reduction), storage temperature -35-85 ℃, humidity 10-90% (no condensation), altitude<1500m

Core interface wiring

The manual provides detailed specifications for the wiring definitions of interfaces such as J1 (power supply), J2 (motor), J3 (feedback), J4 (instruction I/O), J5 (serial port), J11/J12 (SynqNet), etc. The core points are:

Power wiring: AC models need to distinguish between control power (C1/C2) and motor power (L1/L2/L3), DC models need to distinguish between+BUS (main power) and+CTRL (control power), and grounding must comply with PE specifications

Motor wiring: The 3-phase motor is connected to the U/V/W phase and needs to match the motor polarity. The motor casing needs to be grounded

Feedback wiring: SFD feedback uses J3 interface (IEEE1394 style), Hall feedback connects CU/CV/CW pins, incremental encoder supports RS422 differential input

Instruction I/O wiring: Analog instructions support differential input, universal input voltage ± 4-30V, universal output maximum 30V/50mA, step direction instructions support differential drive

Parameter Configuration and Control Mode

Basic switch configuration

S2 dip switch (4 positions): S2-1 sets control mode (torque/speed), S2-2 sets feedback type (SFD/6-step Hall), S2-3/4 reserved

S1 rotary switch (10 positions): Set the analog encoder resolution (500-10000 lines/revolution) for SFD feedback, and set the current loop gain KIP for 6-step mode

SynqNet ID switch (S11/S12): Set the network node ID and support reading through Motion Console

Core parameter configuration

Parameter Category Key Parameter Function Description Value Range

Current loop KIP current loop proportional gain 79.226-19014 V/A

Speed loop KVP speed loop proportional gain 221.0e-6-25.09 ARMS/rad/sec

Speed loop KVI speed loop integral gain 0-753.9 Hz

Position Loop KPP Position Loop Proportional Gain 0.379-93.99 Hz

Position loop KVFF position loop feedforward gain 0-199%

Current limit ILmtPlus/ILmtMinus positive and negative direction current limit 0-100% DIpeak

Feedback configuration AuxFBDivisor auxiliary feedback frequency division coefficient 1-2147483647

Command configuration: The gain/offset of the command is adjusted according to the control mode

Control mode configuration

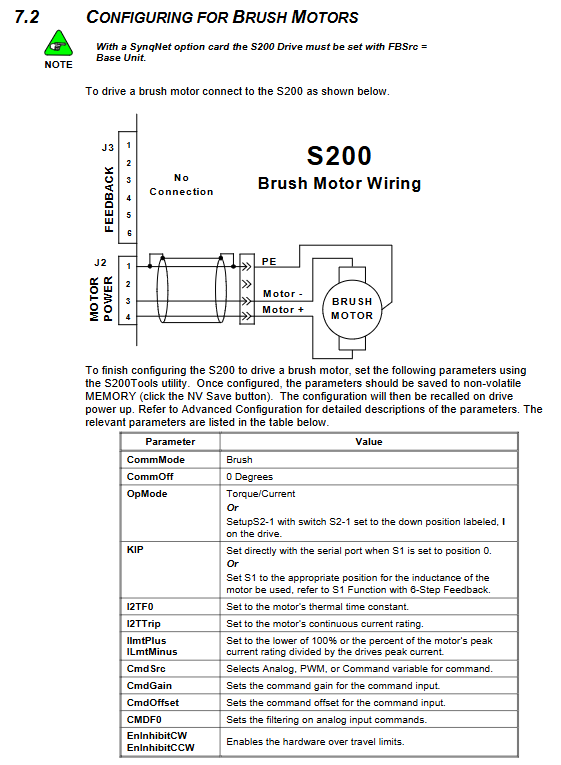

Torque/current mode: supports analog/PWM/software commands, requires setting KIP, I2TF0 (thermal time constant), I2TTrip (thermal protection threshold)

Speed mode: Supports simulation/PWM/software instructions, requires setting KVP, KVI, ARF0/ARF1 (anti resonance filter)

Position mode: Supports step direction or AquadB commands, requires setting GearIn/GearOut (electronic gear ratio), PosCMDSrc (command source)

Feedback adaptation: SFD feedback can automatically load motor parameters, Hall feedback requires setting KIP, EnDat feedback requires configuring AuxFBType

Troubleshooting and Maintenance

Core fault codes and troubleshooting

Fault code (LED flashing frequency), common fault types, troubleshooting methods

2. Check the ambient temperature for motor overheating, motor overload, and poor heat dissipation, reduce the load, and improve heat dissipation

3. Insufficient heat dissipation gap for over/under temperature of the drive, overload operation, and excessive ambient temperature. Clean the heat dissipation channel, reserve sufficient gap, and operate at reduced capacity

7 Bus overvoltage input voltage too high, excessive regenerative energy check input voltage, install regenerative resistor, increase bus capacitance

8 bus undervoltage, DC input voltage below 20VDC, AC input abnormal. Check the power supply voltage and troubleshoot loose wiring

9. Motor short circuit, motor winding short circuit, cable damage detection, motor winding resistance, cable replacement

17 SFD communication fault feedback cable not connected, poor shielding, interference check feedback wiring, ensure shielding grounding, away from interference sources

Key points of daily maintenance

Regular inspection: cleaning of heat dissipation channels, fastening of wiring, connector status, motor temperature

Parameter maintenance: Regularly backup parameter configuration files (in. S2C format) to avoid accidental modification of key parameters

Cable maintenance: Avoid excessive bending of cables, check the integrity of the shielding layer, and pay attention to voltage drop for long cables

Regenerative resistor maintenance: In high regeneration scenarios, it is necessary to check the temperature of the resistor to ensure good heat dissipation and that the cable meets the withstand voltage requirements (300VAC)

Accessory Selection and Compliance Certification

Core Accessories

Accessory Type Model Example Function Description

Communication cable P7S2-232-9D RS232 serial port cable (DB9 to Mod Jack, 6 feet)

Connector kit CK-S200-MF motor power supply+feedback connector kit

Feedback cable CF-DA0111N-XX-X SFD feedback cable (motor end Euro interface, driver end IEEE1394)

Power cable CP-102AAAN-XX-X motor power cable (Euro interface)

Composite cable CC-D01CO2N-XX-X integrated power supply+feedback composite cable

Regenerative resistor 36 Ω/25 Ω/15 Ω absorbs regenerative energy to avoid bus overvoltage

Compliance Certification

Electrical safety: UL508C, cUL certification, compliant with EN50178 standard

EMC compliance: CE certification, compliant with EN61800-3 standard, requiring external filters (such as MTE RF30006-4)

Environmental compliance: RoHS compliance (products produced after November 2007)

Mechanical safety: protection level IP2X (after installation), pollution level 2

SynqNet Exclusive Configuration

SynqNet models (- SRS/- SDS) support SynqNet motion networks, with core features:

Interface type: - SRS is an RJ45 interface, - SDS is a Micro-D interface

Network configuration: Supports multi node cascading, with node IDs set through S11/S12 switches

Feedback support: Aux feedback (Sin Cos, EnDat2.1/2.2) supported through J14 interface

Parameter access: Supports accessing parameters through MPI library or sqDriveParam/sqDriveConfig tool

Real time monitoring: supports monitoring real-time data such as motor current, position, speed, etc

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923