K-WANG

ABB FOUNDATION ™ Fieldbus Link Device LD 810HSE Ex V1.0

Physical and power characteristics: Protection level is IP20, supporting DIN rail installation; Powered by 24V DC, compatible with Ethernet transmission rates of 10 Mbit/s or 100 Mbit/s, and supports device redundancy configuration to enhance operational reliability in industrial scenarios.

ABB FOUNDATION ™ Fieldbus Link Device LD 810HSE Ex V1.0

Equipment positioning and core attributes

Product type: LD 810HSE Ex is a foundation launched by ABB ™ The Fieldbus (Foundation Fieldbus) connection device is registered as a 42c class device according to the HSE protocol specification. Its core function is to serve as a gateway between the FF-HSE (Foundation High Speed Ethernet) subnet and the FF-H1 link, enabling data exchange and management between different bus networks.

Physical and power characteristics: Protection level is IP20, supporting DIN rail installation; Powered by 24V DC, compatible with Ethernet transmission rates of 10 Mbit/s or 100 Mbit/s, and supports device redundancy configuration to enhance operational reliability in industrial scenarios.

Core functions

(1) Gateway core capability

LD 810HSE Ex serves as a gateway, responsible for key data exchange and device management between the FF-HSE subnet and the FF-H1 link. Its specific functions are as follows:

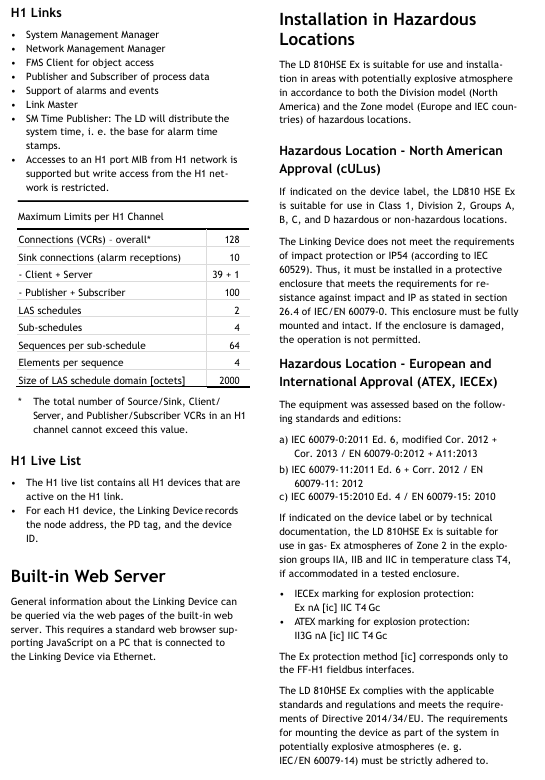

H1 Device Management: Automatically identify all devices connected to the H1 link and configure these H1 devices through the HSE network using System Management and Network Management functions; Simultaneously supporting the access of H1 device function blocks through HSE, enabling remote control and parameter reading of on-site devices.

Data forwarding and synchronization: supports process data forwarding between H1 links, as well as bidirectional process data forwarding between H1 and HSE subnets, ensuring real-time data interoperability at different network levels; As an SM Time Publisher, it distributes system time to H1 devices and provides a unified time reference for alarm timestamps.

Alarm and Event Distribution: Collect alarm and event information sent by H1 devices and distribute it to relevant devices (such as connectivity servers) in the HSE subnet, integrating it into the overall system's alarm management system.

(2) HSE side functional module

Management Agent: Integrate System Management Agent and Network Management Agent to achieve standardized management of HSE subnets and associated H1 links.

Data exchange: Built in FMS server (Fieldbus Message Specification Server) provides object access services for H1 devices; Support the publishing/subscribing mechanism for H1 device process data to meet the real-time data transmission needs in industrial scenarios.

Time synchronization and maintenance: As an SNTP server (Simple Network Time Protocol Server) that complies with HSE standards, it achieves time synchronization within the HSE network; Provide maintenance functionality through a built-in web server, supporting firmware updates for linked devices and H1 power modules via HTTP or HTTPS protocols.

Function limitation: does not support Simple Network Management Protocol (SNMP); There is a clear resource limit on the HSE side, with specific parameters as shown in the table below:

HSE resource type upper limit value

64 HSE sessions have been configured

400 HSE virtual communication relationships (VCRs) have been configured

Automatic HSE session count 32

128 automatic HSE virtual communication relationships (VCRs)

H1-H1 data forwarding count 64

(3) H1 Link Side Function Module

Management and Data Interaction: Integrate System Management Manager and Network Management Manager to lead the management logic of H1 link; As an FMS client, it implements object access while supporting the publication and subscription of process data, as well as the reception and reporting of alarms and events.

Link Control: Serve as the Link Master in each H1 link, responsible for communication scheduling and resource allocation of the link; Support access to the Management Information Base (MIB) of H1 port from H1 network, but restrict write operations from H1 network to ensure network security.

Resource limit (single H1 channel): There are clear restrictions on the resource configuration of each H1 channel, with specific parameters as shown in the table below (note: the total number of VCRs of source/sink, client/server, and publisher/subscriber types in a single H1 channel must not exceed the "total connections" limit):

H1 channel resource type upper limit value

Total number of connections (VCRs) * 128

Number of overnight connections (alarm reception) 10

Number of client server connections: 39+1

Publisher+subscriber connections 100

LAS scheduling table quantity 2

Number of sub scheduling tables 4

The number of sequences in each sub schedule table is 64

The number of elements in each sequence is 4

LAS scheduling table field size (bytes) 2000

(4) H1 Live List

Record key information of all active H1 devices on the H1 chain, including node addresses, PD tags (Process Data Tags), and device IDs, to provide basic data support for device management and troubleshooting.

(5) Built in web server

Support access through a standard web browser (with JavaScript enabled) to query general information of linked devices (such as device status, configuration parameters, etc.), provided that the PC where the browser is located is connected to LD 810HSE Ex via Ethernet.

Installation and certification in hazardous environments

(1) Applicable environmental model

LD 810HSE Ex is suitable for scenarios with potential explosive environments and complies with the hazardous location classification requirements of the North American "Division model" and the European and IEC national "Zone model".

(2) North American Certification (cULus)

Scope of application: If the equipment label has clear identification, it can be used in Class 1, Division 2, A/B/C/D hazardous or non hazardous locations.

Installation requirements: The equipment itself does not meet the requirements of impact resistance and IP54 (according to IEC 60529), and must be installed in a protective enclosure that complies with section 26.4 of IEC/EN 60079-0 (must meet the requirements of impact resistance and IP rating); The casing must be fully installed and undamaged. If the casing is damaged, the equipment is prohibited from operating.

(3) European and international certifications (ATEX, IECEx)

Certification criteria:

IEC 60079-0:2011 6th edition (including 2012 and 2013 revisions)/EN 60079-0:2012 (including A11:2013 revisions)

IEC 60079-11:2011 6th edition (including 2012 revision)/EN 60079-11:2012

IEC 60079-15:2010 4th edition/EN 60079-15:2010

Scope of application: If the equipment label or technical documentation clearly identifies it, it can be used in Zone 2 gas explosive environments with IIA, IIB, IIC explosive groups, T4 temperature levels after being installed in a tested protective enclosure.

Explosion proof label:

IECEx explosion-proof label: Ex nA [ic] IIC T4 Gc

ATEX explosion-proof label: II3G nA [ic] IIC T4 Gc

Note: [ic] Explosion proof method is only applicable to the FF-H1 fieldbus interface.

Compliance requirements: The equipment complies with relevant standards and regulations, and meets the requirements of Directive 2014/34/EU; When installed as part of a system in potentially explosive environments, it is necessary to strictly comply with the requirements of standards such as IEC/EN 60079-14.

At ABB Ability ™ Integration in IT system (800xA system)

(1) System Architecture Role

In a typical 800xA system architecture, FOUNDATION ™ The Fieldbus subsystem is connected to the control system (such as the AC 800M controller) through the HSE subnet, with LD 810HSE Ex serving as the gateway to establish a communication bridge between the field devices on the H1 link and the HSE subnet. The specific architecture is as follows:

Upper level system: including engineering workstation (Control Builder M workstation), operator maintenance workstation, Fieldbus Builder FF client/server network, and connectivity server with OPC server (FF Connectivity Server).

Control layer: The AC 800M controller is connected to the HSE subnet through the communication interface module CI860 (as the HSE host) to achieve control and data exchange of the Fieldbus subsystem.

Fieldbus subsystem: composed of multiple LD 810HSE Ex linked devices and H1 field devices, the linked devices communicate through HSE protocol and manage the H1 links under them, realizing the forwarding of process data and device management.

(2) Key integration capabilities

Data exchange: With the help of HSE data forwarding function, periodic communication between different H1 link on-site devices and HSE subnet devices can be configured to meet real-time control requirements.

Alarm integration: The alarms and events of H1 devices are transmitted to the FF connectivity server through linked devices, seamlessly integrated into the alarm management system of the 800xA system for unified monitoring and processing.

Redundant configuration: Supports LD 810HSE Ex redundant deployment, where the corresponding H1 ports of two physically linked devices in the redundant group are connected to the same H1 link, and redundant control information is exchanged through redundant link wiring to enhance system reliability.

Technical specifications and parameters

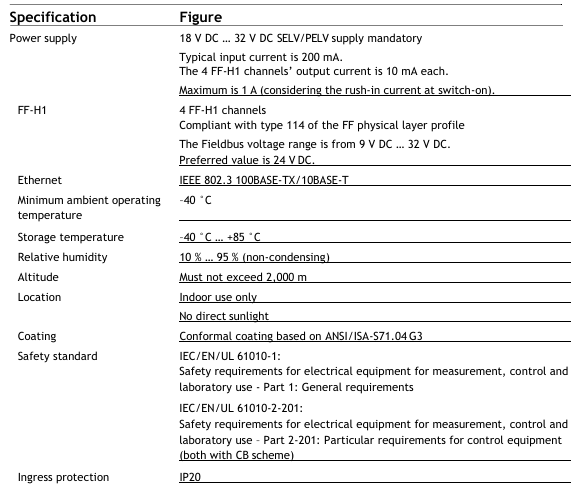

Technical parameter category specific parameters

Power supply input voltage: 18 V DC~32 V DC (mandatory requirement for SELV/PELV power supply); Typical input current: 200 mA; 4 FF-H1 channels output current: 10 mA each; maximum input current: 1 A (including startup surge current)

FF-H1 channel quantity: 4; Compliant with FF physical layer protocol specification Class 114; Fieldbus voltage range: 9 V DC~32 V DC (recommended value 24 V DC)

Ethernet complies with the IEEE 802.3 standard; Supports 100BASE-TX (100 Mbit/s) and 10BASE-T (10 Mbit/s)

Environmental temperature: Operating temperature: -40 ° C~+70 ° C; Storage temperature: -40 ° C~+85 ° C

Relative humidity 10%~95% (non condensing)

The highest altitude shall not exceed 2000 meters

Installation location for indoor use only; Avoid direct sunlight

The coating complies with the ANSI/ISA-S71.04 G3 standard and is a three proof coating (moisture-proof, salt spray resistant, and mold resistant)

The safety standards comply with IEC/EN/UL 61010-1 (Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use - Part 1: General Requirements) and IEC/EN/UL 61010-2-201 (Part 2-201: Special Requirements for Control Equipment), both of which have passed the CB certification system

Protection level IP20

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923