K-WANG

Bender LifeGuard® LG2-Series Protection Panels

Bender LifeGuard ® LG2-Series Protection Panels

Product Overview

Bender LifeGuard ® The LG2 series is an industrial grade ground fault protection panel launched by Bender. Its core mission is to monitor the ground fault current in the circuit in real time, and quickly cut off the load power supply when the current reaches the preset trip threshold, avoiding safety risks such as electric shock and arc flashover. The product is suitable for industrial circuits with multiple voltages and phases, providing flexible installation forms and trip level selection. It strictly follows the UL 508A industrial control panel standard and is widely used in factory equipment, industrial control systems, and other scenarios that require extremely high electrical safety.

Core parameters and specifications

Category specific parameters

Adaptation voltage 120VAC、208VAC、208/120VAC、240/120VAC、480VAC、480/277VAC、600VAC、600/347VAC

Circuit phase 1ph (2w/3w), 3ph (3w/4w)

Rated current < 100A, 100A

Release level F: Fixed 6mA; Level A: Adjustable on-site (default 30mA)

Shell type NEMA 4X polycarbonate, NEMA 4X stainless steel, backplate only (requires self provided cabinet)

Dimensions (length × width × depth) < 100A: 305 × 254 × 152mm (12 "× 10" × 6 "); 100A: 406 × 356 × 203mm (16" × 14 "× 8")

The wire requirement is only copper wire; <100A requires ≥ 60 ℃ (140 ℉) rating; 100A needs to be rated at ≥ 75 ℃ (167 ℉)

Installation and wiring specifications

(1) Installation requirements

Installation of shell:

NEMA 4X polycarbonate/stainless steel casing with wall mounting feet, separate wall mounting instructions must be followed;

It is recommended to use NEMA 4X or higher grade connectors at the bottom of the casing for cable perforation to maintain the protection level.

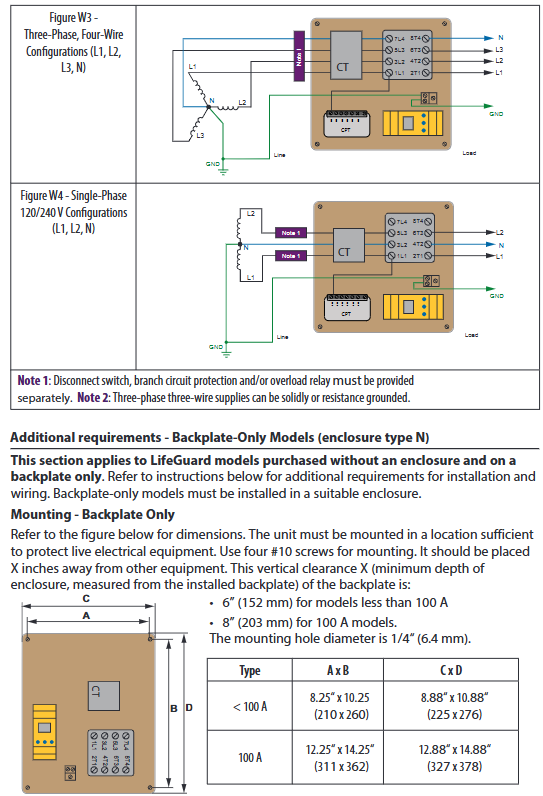

Only for backplate installation:

It needs to be installed in a compliant cabinet, with vertical clearance requirements of 152mm (6 ") for<100A and 203mm (8") for 100A;

Fix with 4 # 10 screws, with a mounting hole diameter of 6.4mm (1/4 ").

(2) Wiring rules

Installation must be carried out by licensed electricians, following local, state, and national electrical regulations;

All active conductors (including neutral wire N) need to pass through a current transformer and be connected to the incoming side of the contactor;

Connect the load or protected branch to the outgoing side of the contactor;

The incoming and load grounding wires must be connected to the backplane grounding terminal and must not pass through the current transformer;

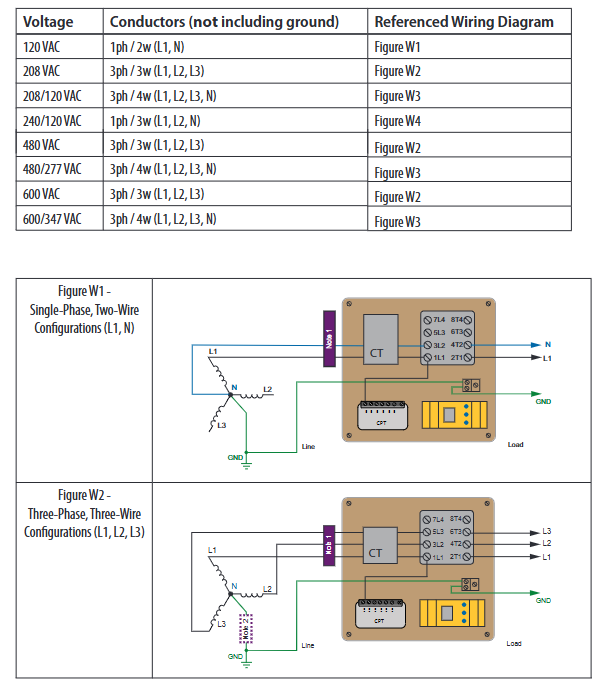

The number of conductors and wiring diagrams corresponding to different voltages are as follows:

Reference wiring diagram for voltage specification, number of conductors (excluding grounding)

120 VAC 1ph/2w(L1、N) Figure W1

208 VAC 3ph/3w(L1、L2、L3) Figure W2

208/120 VAC 3ph/4w(L1、L2、L3、N) Figure W3

240/120 VAC 1ph/3w(L1、L2、N) Figure W4

480 VAC 3ph/3w(L1、L2、L3) Figure W2

480/277 VAC 3ph/4w(L1、L2、L3、N) Figure W3

600 VAC 3ph/3w(L1、L2、L3) Figure W2

600/347 VAC 3ph/4w(L1、L2、L3、N) Figure W3

Core functions and operating procedures

(1) Release level and range adjustment

Release level, release current adjustment method, current sensor range setting (potentiometer)

F-class fixed 6mA non adjustable --

A-level on-site adjustable (default 30mA) potentiometer adjustment CTUB101-CTBC35P ≤ 100mA: left position (8 o'clock direction); >100mA: median (12 o'clock direction)

(2) Basic operations

Power on: Close the circuit breaker/isolation switch on the incoming side, and the green POWER ON LED will light up when there is no ground fault;

Test (F level, fixed 6mA):

Press and hold the TEST button for ≥ 2 seconds, the device will trip, the red CIRCUIT TRIPPED LED will light up, and the load will be powered off;

After internal self check for about 10 seconds, press and hold the RESET button for ≥ 1 second to reset the device and restore power supply;

Test (Grade A, adjustable on site):

Press and hold the TEST button for ≥ 2 seconds, the device will trip, and the red LED will light up;

Press and hold the RESET button for at least 1 second to reset the device and restore power supply;

Range adjustment (Class A only):

Adjust the potentiometer according to the trip setting of RCMA420-D-2, with the corresponding range as follows:

Release current range, effective value measurement range, peak measurement range

I∆n ≤0.1A 0~450mA 0~900mA

0.1A<I∆n ≤0.5A 0~0.75A 0~3.5A

Safety and Compliance

Before installation, all power sources must be disconnected to avoid the risk of electric shock and arc flashover;

Separate isolation switches, branch protections, and/or overload relays need to be configured;

The three-phase three wire system can adopt direct grounding or resistance grounding methods;

Equipment troubleshooting and parameter adjustment should refer to the technical manual for protective relays (available online).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923