K-WANG

BENDER Isolated Power Panels

BENDER Isolated Power Panels

Product Overview

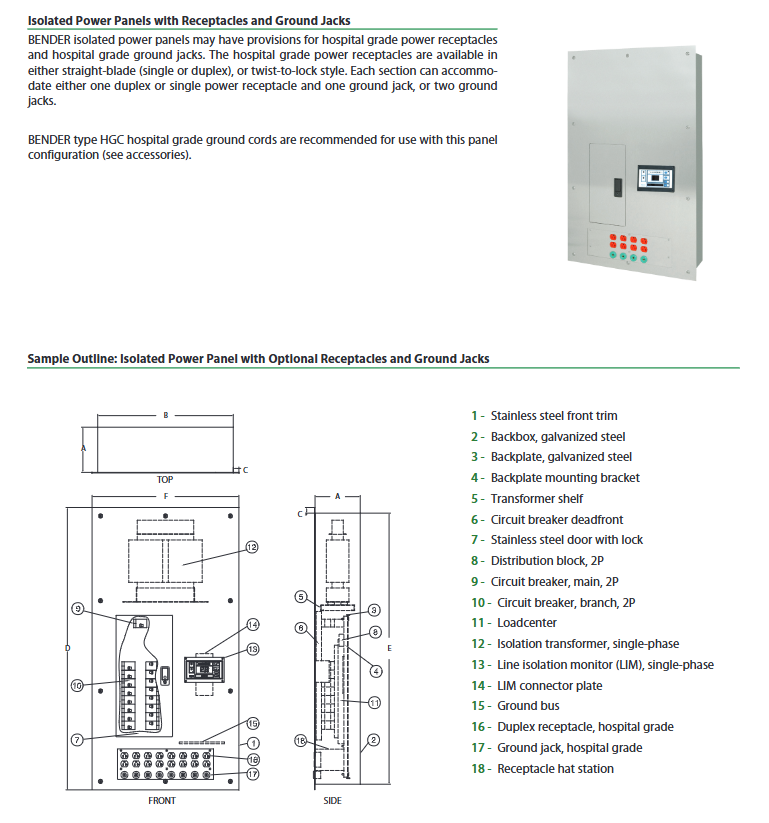

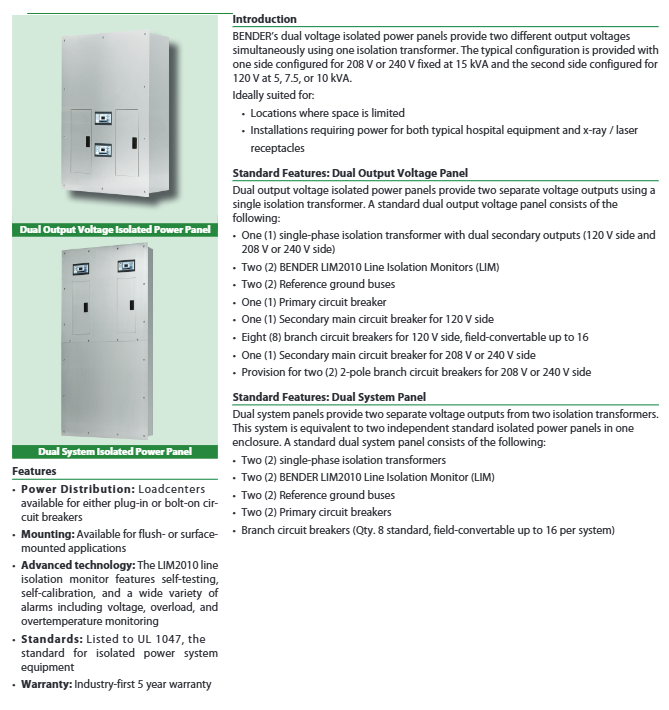

BENDER isolated power panel is a safe power supply solution designed for critical medical areas. The core goal is to achieve equipotential power supply through isolation transformers and precise monitoring technology, avoiding the risk of electric shock caused by grounding faults. The product is divided into three categories: standard type, dual output voltage type, and dual system type. It can expand sockets, grounding components, and fault location systems according to the needs of medical scenarios, and is equipped with communication gateways and remote indicators to form a "power supply monitoring positioning monitoring" full chain safety system. It strictly follows the electrical standards of the medical industry and is suitable for scenarios such as operating rooms and intensive care units that require extremely high reliability and safety of power supply.

Comparison of core models and configurations

Model Series Core Features Power Range Voltage Output Key Configuration Applicable Scenarios

Standard Type (IP) Single Isolation System 3kVA~25kVA Single Voltage (120V/208V/240V, etc.) 1 LIM2010, 8-way Branch Circuit Breaker (expandable 16 ways) General Intensive Care Unit, Diagnosis and Treatment Room

Dual output voltage type (ID) single transformer dual secondary 25kVA 120V+208V/240V 2 LIM2010, dual grounding bars, independent branch circuits with limited space and multiple voltage scenarios required

Dual system type (IX) with two independent isolation systems, each with a voltage output of 3kVA~10kVA. Each system has two independent voltage outputs, including two isolation transformers and two LIM2010 operating rooms with high reliability requirements

Core component specifications

(1) Isolation transformer

Power specifications support voltage (primary/secondary) adaptation model series

3kVA/5kVA 120V~480V/120V~240V IP series

7.5kVA/10kVA 120V~480V/120V~240V IP/IX series

15kVA/25kVA 120V~480V/120V~240V IP/ID series

(2) LIM2010 Line Isolation Monitor

Display mode: digital+analog dual display

Response value options: 2mA, 5mA

Alarm function: overvoltage/undervoltage, overload, overheating, grounding fault

Core features: self checking and self calibration, support for EDS fault location expansion

Communication interface: compatible with RS-485, can be connected to centralized monitoring system

(3) Fault location system (EDS461 series)

Module model, display type, output interface, core parameters

EDS461-D LCD displays 1 DPDT contact supporting 12 current transformers, RS-485 interconnection

EDS461-L LED indicates 1 DPDT contact supporting 12 current transformers, RS-485 interconnection

Scalability: up to 90 EDS modules interconnected, supporting 708 sub loop monitoring

Positioning method: Receive LIM2010 test pulses and identify faulty circuits through current transformers

Installation and Extension Options

(1) Installation method and size

Installation type, bottom box material, size example (height x width x depth), compatible model

Embedded 14GA galvanized steel 43 "× 24" × 6 "(3/5kVA) IP/ID/IX series

Surface mounted 14GA galvanized steel (ivory white baked paint) 43 "× 24" × 6 "(3/5kVA) IP/ID/IX series

Panel Material: 14GA 304 Stainless Steel (# 4 brushed) Embedded Panel 1 "Larger than Bottom Box, Full Series

(2) Extension function options

Distribution Expansion:

Circuit breaker types: Plug On (Square D/Cutler Hammer/GE), Bolt On

Current specifications: 20A/30A/50A/60A, supports 2P configuration

Socket and grounding:

Socket type: direct insertion single/double (red/ivory white), twist lock type (black)

Grounding components: Hospital grade grounding socket, HGC series grounding cable (10/12/15 feet)

Control extension:

PLC control module: supports 12 channels of X-ray/laser equipment power supply, including threshold switch and "in use" indicator light

Load monitoring: STW series current transformers achieve transformer overload monitoring

Communication and Remote Monitoring

(1) Communication gateway

Model Communication Protocol Core Functions

COM460IP Ethernet, Modbus/TCP web monitoring, email/SMS alarm, remote access

FTC470XMB Modbus/RTU connects 10 BENDER devices and integrates them into the building management system

FTC470XDP Profibus/DP is compatible with industrial bus systems and supports device control

(2) Remote indicator

Series Core Features Featured Models

MK2000 sound and light alarm, mute function MK2000CBM (with digital display and overload indication)

MK2430/MK800 LCD displays fault location and testing function MK2430-11 (12 channel digital input)

RAS series multi-channel centralized indicator RAS-04B (integrated with 4 indicators)

Key issues

Question 1: What are the core differences among the three core models of BENDER isolated power panels (standard type, dual output voltage type, dual system type)? How to choose based on the scenario?

Answer: The core differences are concentrated in the power supply system architecture and voltage output capability. The selection logic is as follows: ① Standard type (IP series): single isolation system+single voltage output, power 3kVA~25kVA, suitable for most intensive care units, diagnosis and treatment rooms and other single voltage demand scenarios; ② Dual output voltage type (ID series): single 25kVA transformer+dual secondary winding, simultaneously outputting 120V and 208/240V, equipped with dual LIM2010 monitors, suitable for space limited scenarios that require power supply for both ordinary medical equipment (120V) and high-power equipment (208/240V); ③ Dual system type (IX series): Two independent isolation systems, each equipped with transformers and monitors, supporting seamless switching in case of faults, suitable for critical scenarios such as operating rooms that require extremely high power supply reliability.

Question 2: What is the core function of LIM2010 line isolation monitor? How to quickly locate grounding faults?

Answer: The core function of LIM2010 is: ① Real time monitoring of the insulation status of the isolated power supply system, supporting 2mA/5mA response value setting, with digital and analog display; ② Equipped with self checking and self calibration functions, it can monitor faults such as overvoltage, undervoltage, overload, and overheating and trigger sound and light alarms; ③ Support linkage with EDS461 series fault location module. Rapid positioning process for grounding faults: ① LIM2010 triggers an alarm after detecting a grounding fault; ② EDS461 module automatically activates and receives test pulses sent by LIM2010; ③ The current transformers distributed in each branch circuit capture pulse signals; ④ EDS461 analyzes signals through RS-485 interconnection and displays the fault circuit location on LCD/LED; ⑤ Remote indicator synchronous alarm, supporting up to 708 sub loop monitoring.

Question 3: What are the expansion capabilities of BENDER isolated power panels reflected in? How to achieve centralized management of communication monitoring system?

Answer: The expansion capability is mainly reflected in three aspects: ① Distribution expansion: Standard 8-way branch circuit breakers can be expanded to 16 ways, supporting Plug On/Bolt On two types, with current specifications covering 20A-60A; ② Function extension: Can add hospital level sockets, grounding sockets, PLC control modules (up to 12 device controls), EDS461 fault location system; ③ Monitoring Expansion: Supports MK series remote indicators and sound and light alarms, and connects to a communication gateway for centralized management. Centralized communication management method: ① Hardware level: Connect all devices through COM460IP (Ethernet/Modbus/TCP) or FTC470XMB (Modbus/RTU) gateway; ② Functional aspect: Real time viewing of device status and fault location on the web page, supporting email/SMS alarm push; ③ System integration: Compatible with OPC servers and SCADA/BMS building management systems, achieving unified monitoring of medical area power supply systems.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923