K-WANG

YOKOGAWA LS3300 AC Power Calibrator

YOKOGAWA LS3300 AC Power Calibrator

Product basic information

1. Product positioning and core functions

LS3300 is an AC power calibrator that uses the "phantom load method" to generate AC voltage, current, and power signals. It is mainly used for calibrating power meters and other equipment, supporting multiple wiring systems and synchronous operations to meet calibration needs in different scenarios.

2. Manual system and language version

Supporting manual: In addition to this manual, it also includes Chinese specific documents (IM LS3300-92Z1), European language safety manual (IM 00C01C01-01Z1), and global contact list (PIM 113-01Z2).

Language code: The "EN" in the manual number represents English, and "Z1" represents other languages such as Chinese. Users can obtain the corresponding version according to their needs.

Manual update: The content may change without prior notice due to product performance/feature upgrades. The latest version should refer to the official website; As of April 2025, it is the 8th edition, and the historical version gradually iterates from the 1st edition in August 2017.

Preparation before use

1. Packaging content inspection

Host and identification: Confirm that the host model is LS3300 (specification 1200V, 60A), and verify the model and suffix code through the side panel nameplate to avoid misdelivery.

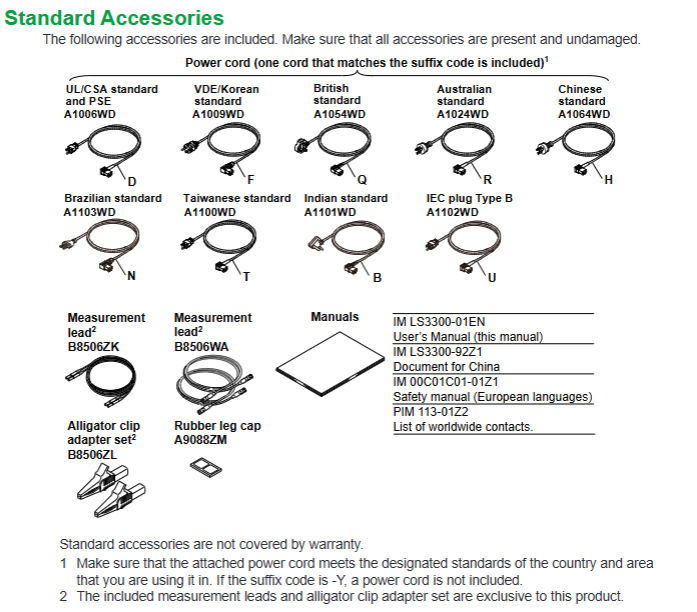

Standard accessories: including 1 power cord with matching suffix code (such as - H for Chinese standard, - Q for British standard, etc., - Y without power cord needs to be provided), measuring wire (B8506ZK/B8506WA), crocodile clip adapter set, rubber foot cap, and complete manual. Confirm that the accessories are intact.

Optional accessories: Measurement wire, crocodile clip adapter, BNC cable, rack installation kit, etc. need to be purchased separately, and the selection needs to match the rated parameters of the equipment (such as 758917 measurement wire rated 1000V, 32A).

2. Installation and power connection

Installation requirements: It should be installed in a well ventilated area, with sufficient space reserved for the top/bottom air outlet and rear air inlet (top/bottom ≥ 20cm), avoiding direct sunlight, humidity, strong magnetic fields, and other environments; Supports desktop placement (adjustable movable feet) or rack installation (requires specialized kit), and is prohibited for outdoor or water environments.

Power specifications:

Rated voltage: 100-120VAC or 200-240VAC, allowable fluctuation range 90-132VAC, 180-264VAC, frequency 50/60Hz (allowable fluctuation range 48-63Hz).

The power cord must be designed specifically for the device and comply with local standards (such as the - H type used in China, rated at 250V). It must be plugged into a three hole socket with protective grounding. It is prohibited to cut off the grounding wire or use ungrounded extension cords.

Core functions and operations

1. Output parameter settings

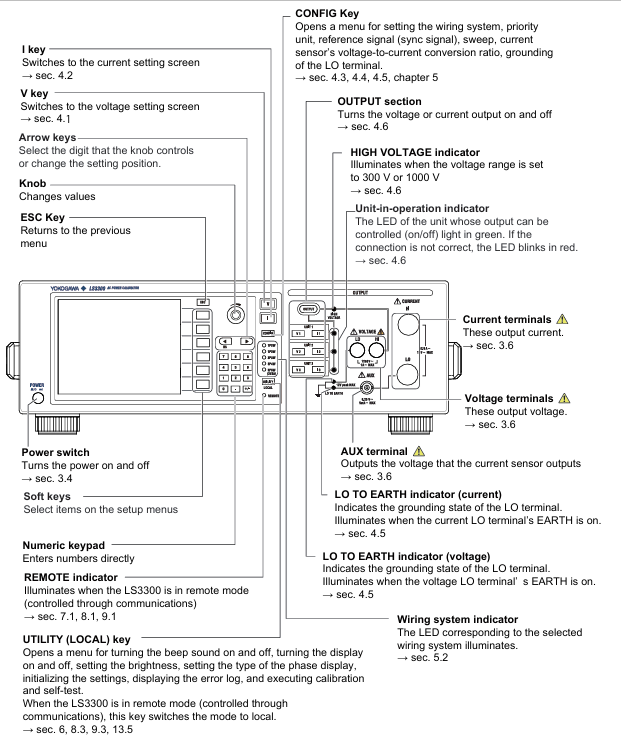

(1) Voltage output setting

Range and Range: Supports ranges of 1V, 10V, 30V, 100V, 300V, and 1000V, with an output range of 0-125% of each range (set by "output level x level ratio", level ratio 0-120%). For example, a 10V range can output a maximum of 12.5V.

Key parameters: frequency 40-1200Hz, phase -180 ° to+359.999 °, power factor -1.0 to 1.0 (lead/lag can be set); When the voltage is ≥ 150V, a buzzing warning will be issued, and when the range is ≥ 300V, the "high voltage indicator light" will light up.

(2) Current output setting

Range and Range: The basic range is 30mA, 100mA, 1A, 10A, 50A, and can be extended to 20A, 30A, 100A, 150A when synchronizing multiple devices; Supports "external sensor mode" (500mV/5V output, voltage current conversion ratio needs to be set), with the same output range as the voltage logic (0-125% range).

Key parameters: Frequency, phase, power factor settings should be consistent with voltage. For high current outputs (such as 20A and above), the wiring system should be set to "1P2W (HI Current)" and multiple devices should be synchronized.

(3) Scanning function (Sweep)

Function purpose: By linearly adjusting the level ratio, the output can smoothly change within a specified range (such as checking for meter pointer sticking), supporting separate scanning of voltage/current.

Parameter settings: Scanning range 0-100%/105%/110%/120% (relative to output level), scanning time 8s/16s/32s/64s (time from 0% to 100%), can be set to "UP" or "DOWN", and will automatically hold when reaching the limit value.

2. Synchronous operation and wiring system

(1) Synchronization function

Multi device synchronization: Supports up to 3 LS3300 devices for synchronization, or synchronization with external devices such as 2558A; The master device is connected to the slave device's "OSC INPUT" terminal through the rear "OSC OUTPUT" terminal, synchronizing frequency and phase (external device synchronization only ensures frequency consistency, phase needs to be manually adjusted).

Synchronization settings: Set the master device to "INTernal" and the slave device to "EXTernal"; The "LINE" mode can also be set to synchronize the output with the power frequency.

(2) Wiring system

Supports 6 types of wiring systems, which need to be selected according to the calibration scenario. Different systems correspond to different device connection methods:

The number of devices required for the applicable scenarios of the wiring system

Single phase two-wire (1P2W) independent calibration of one device

Single phase two-wire (1P2W HI Current) high current output (20A and above) 2-3 units

Calibration of 2 single-phase three wire (1P3W) single-phase three wire systems

Three phase three wire (3P3W) calibration of two three-phase three wire systems

Three phase three wire (3V3A) three-phase three wire (three voltage three current method) calibration for 3 units

Three sets of three-phase four wire (3P4W) three-phase four wire system calibration

3. Other functions

Beeming control: Beeming can be turned on/off (such as voltage ≥ 150V, scan hold, etc.), but it cannot be turned off due to equipment failure (such as fan stoppage, overheating).

Display settings: Supports LCD screen off (wake up by pressing any key), brightness adjustment (0-10 levels), phase display is divided into Type1 (0 ° to the right) and Type2 (0 ° to the top).

Error log: Record error codes that occur during device operation (such as E.030 amplitude control error), clear after power failure, and can be viewed or cleared through the "UTILITY" menu.

Initialization: The device settings can be restored to factory default (except GP-IB and Ethernet settings), and in synchronous mode, the master device initialization will synchronize with the slave devices.

Communication interface

1. Interface type and specifications

The device supports three interfaces: USB, Ethernet, and GP-IB, which cannot be used simultaneously. Configuration needs to be switched through the "CONFIG" menu:

Interface type, specification parameters, purpose

USB 2.0 (HS/FS mode), supports USB-TMC protocol, connects to PC via Type B interface, and controls devices through USB-TMC commands

Ethernet 10BASE-T/100BASE-TX, RJ-45 interface, supports TCP/IP (VXI-11), DHCP network control, up to 3 devices can be connected simultaneously

GP-IB complies with IEEE 488.2 standard, addresses 0-30, supports NI GP-IB card traditional instrument control, and is suitable for GP-IB compatible systems

2. Remote/Local Mode Switching

Remote mode: After receiving a PC command, enter and the "REMOTE" indicator light will turn on. Only the "UTILITY" key can switch back to local mode, and other panel operations are invalid.

Local mode: Press the "UTILITY" key or receive a PC local switch command to enter, and the panel operation will return to normal.

Safety and Maintenance

1. Safety regulations

High voltage protection: The maximum output of the equipment is 1250Vrms. Before operation, remove metal jewelry and do not touch the output terminals or wires (even if the output is turned off, residual voltage may still cause electric shock).

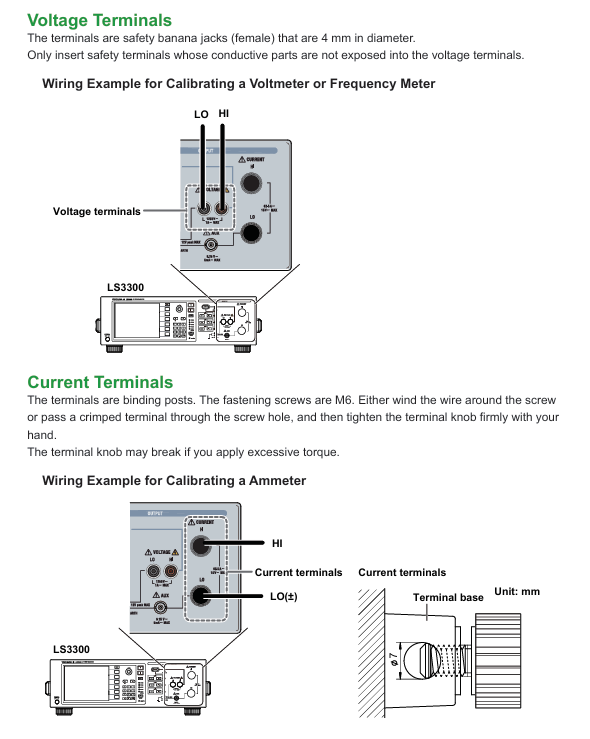

Wiring safety: Before outputting, it is necessary to confirm that the wiring is correct (voltage wire connected to voltage terminal, current wire connected to current terminal, without short circuit/looseness); Do not touch the terminals during output, regularly check if the terminals are overheated or loose.

Fault handling: If there is smoke, odor, or abnormal noise, immediately cut off the power and disconnect the load; When the output automatically shuts off (such as overload protection), the fault needs to be eliminated (such as replacing the load) and then restarted.

2. Maintenance and repair

Filter cleaning: The rear air inlet filter needs to be checked and cleaned every 3 months. If it is dirty, clean it with neutral detergent and let it dry naturally. Blocking can cause the equipment to overheat; The filter screen is damaged and needs to be replaced by contacting a Yokogawa dealer.

Self check function: Automatically perform self check (check fan, voltage/current range, internal circuit) when turned on, or manually through the "UTILITY" menu. If the self check fails, an error code will be displayed (such as E.901 indicating fan failure).

Calibration and replacement: It is recommended to calibrate once a year to ensure accuracy. Cooling fans (3 years), filters (1 year), and LCDs (approximately 40000 hours) should be replaced according to the recommended cycle, and maintenance should be carried out by Yokogawa certified personnel.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923