K-WANG

GE Grid Solutions Hydran M2-X Enhanced Monitoring with Extended Sensor Life

GE Grid Solutions Hydran M2-X Enhanced Monitoring with Extended Sensor Life

Product basic information

Key content of the project

Product Name: Hydran M2-X

Brand owner GE Grid Solutions

Product positioning: A new generation DGA (Dissolved Gas Analysis) monitoring solution that has been validated on-site

Core mission: Monitor the gas and moisture content in transformer insulation oil, warn of faults, extend equipment life, and reduce unplanned shutdowns

With 40 years of experience in online DGA solutions, we have sold over 50000 units worldwide

Warranty and 7-year product warranty; The sensor has a lifespan of over 10 years (based on accelerated aging testing, MTTF is 11.5 years)

Core advantages

Wide adaptability: supports mineral insulating oil, natural and synthetic ester insulating oil transformers

Low maintenance and convenience: miniaturized design, no moving parts; Can be installed through existing transformer valves, usually without the need for shutdown

Functional scalability:

Sensor options: Traditional composite gas sensors (H ₂, CO, C ₂ H ₄) or single H ₂ sensor (mineral oil only)

Scalable monitoring: Connect sensors to monitor top oil temperature and load current, support IEEE transformer model calculation (such as winding hotspot temperature)

On site upgrade: can add analog signal input to monitor more key parameters

Powerful Integration: Supports multiple communication methods and protocols, seamlessly integrates with GE Perception ™、 PREDIX ™ Waiting for digital platforms and SCADA systems

Intuitive operating experience: Built in backlit LCD display (128 × 64 pixels) and keyboard, supporting local data visualization and device configuration

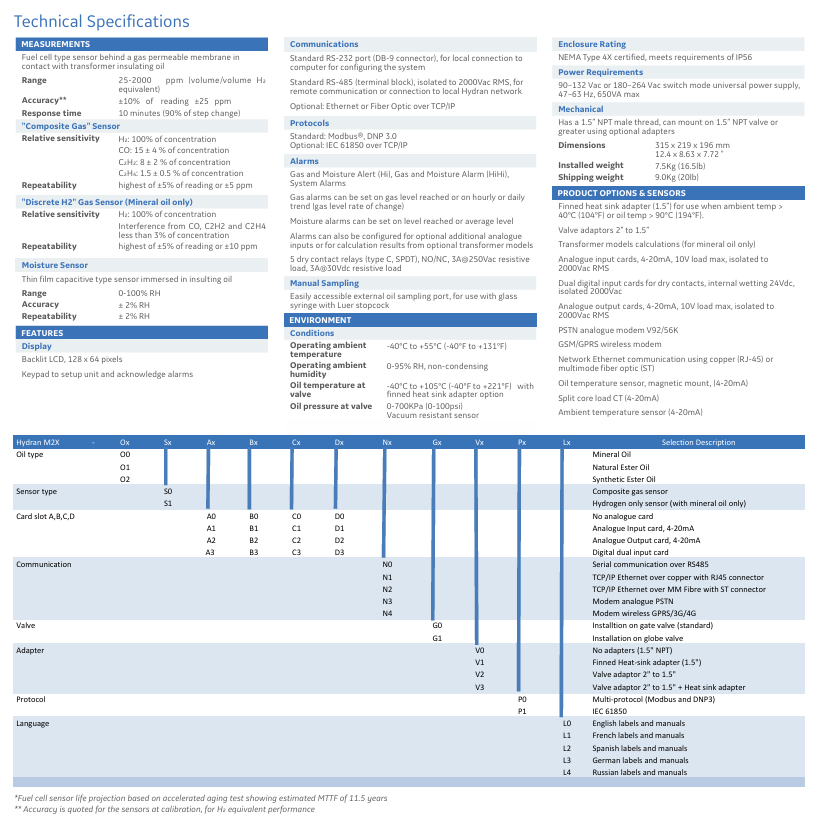

Key technical parameters

(1) Monitoring sensor parameters

Specific parameters of core indicators for sensor types

Composite gas sensor measurement range 25-2000 ppm (volume/volume H ₂ equivalent)

Accuracy ± 10% Reading ± 25 ppm

Response time of 10 minutes (90% of step change)

Relative sensitivity H ₂: 100% concentration; CO: 15 ± 4% concentration; C ₂ H ₄: 1.5 ± 0.5% concentration

Repeatability ± 5% reading or ± 5 ppm (whichever is greater)

Single H ₂ sensor (mineral oil only) relative sensitivity H ₂: 100% concentration; Affected by CO, C ₂ H ₂, C ₂ H ₄ interference

Repeatability ± 5% reading or ± 10 ppm (whichever is greater); Concentration error<3%

Moisture sensor (thin film capacitive) measuring range 0-100% RH

Accuracy ± 2% RH

Repeatability ± 2% RH

(2) Environmental and physical parameters

Category specific parameters

Working environment temperature -40 ° C~+55 ° C (-40 ° F~+131 ° F)

Working environment humidity 0-95% RH (non condensing)

Oil temperature at valve -40 ° C~+105 ° C (-40 ° F~+221 ° F) (optional fin heat dissipation adapter)

The oil pressure at the valve is 0-700KPa (0-100psi), and the sensor is resistant to vacuum

Protection level NEMA Type 4X, compliant with IP56 requirements

Size 315 × 219 × 196 mm (12.4 × 8.63 × 7.72 inches)

Installation weight 7.5Kg (16.5lb)

Transport weight 9.0Kg (20lb)

Installation interface with 1.5 "NPT external thread, can be installed on ≥ 1.5" NPT valves through an adapter

(3) Communication and power parameters

Category specific parameters

Communication interface standards: RS-232 (DB-9 connector), RS-485 (terminal block, 2000Vac RMS isolation); Optional: Ethernet/Fiber (TCP/IP)

Supporting protocol standard: Modbus ®、 DNP 3.0; Optional: IEC 61850 (TCP/IP)

Power requirements: 90-132 Vac or 180-264 Vac switch mode universal power supply, 47-63 Hz, maximum 650VA

Functional characteristics

Alarm function:

Alarm types: gas/moisture warning (Hi), gas/moisture alarm (HiHi), system alarm

Alarm triggering: Gas alarm can be based on concentration, hourly/daily trend (rate of change); Moisture alarm can be based on concentration and average concentration; Support optional simulation input or model calculation result alarm

Hardware support: 5 dry contact relays (C-type SPDT), 3A@250Vac /30Vdc resistive load

Additional features:

Manual sampling: external oil sampling port, compatible with Ruhr stopcock glass syringe

Data management: compatible with GE Perception ™ Software that supports data download and trend analysis

Insulation monitoring: Built in moisture sensor to monitor moisture in oil, identify paper aging and gasket leakage

Application scenarios

Applicable objects: Transformers in the power industry and industrial sector

Integrated configuration: Can be integrated with Kelman multi gas DGA equipment and Multilin 845 protection and control relays to achieve synchronization of chemical and electrical measurements

Core Value: Providing key data for Asset Performance Management (APM), assisting in maintenance plan development, and avoiding catastrophic transformer failures

key issue

Question 1: What is the core monitoring capability of Hydran M2-X? What types of transformer insulation oil are supported?

Answer: The core monitoring capability is to continuously monitor the gases (composite gases: H ₂, CO, C ₂ H ₄) in the insulation oil of transformers; Or single H ₂ and moisture content, with a gas measurement range of 25-2000 ppm (H ₂ equivalent) and a moisture measurement range of 0-100% RH; supported insulation oil types include mineral insulation oil, natural ester insulation oil, and synthetic ester insulation oil (single H ₂ sensor only supports mineral oil).

Question 2: What are the advantages of Hydran M2-X in communication and integration? Which systems/software are compatible?

Answer: Communication advantages include support for multiple interfaces (RS-232, RS-485, optional Ethernet/fiber) and protocols (standard Modbus) ®、 DNP 3.0; Optional IEC 61850, capable of local configuration and remote communication; In terms of integration compatibility, it can be compatible with the GE digital platform (Perception) ™ Transformer Fleet Management Software PREDIX ™、 The DS Agile substation HMI, SCADA system, historians, and APM software tools seamlessly integrate, and can also synchronize data with Kelman multi gas DGA equipment and Multilin 845 protection control relays.

Question 3: In what aspects is the reliability and maintenance convenience of Hydran M2-X reflected? What are the relevant key indicators?

Answer: Reliability is reflected in 40 years of on-site verification, global sales of over 50000 units, 7-year product warranty, sensor lifespan of over 10 years (MTTF 11.5 years), and protection level of IP56, suitable for wide temperature working environments ranging from -40 ° C to+55 ° C; The convenience of maintenance is reflected in the design of no moving parts, low maintenance requirements, on-site upgradability and expansion. During installation, existing transformer valves can be utilized (usually without shutdown), equipped with intuitive LCD display screens and keyboards, supporting local operation and manual sampling, reducing maintenance costs and downtime.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923