K-WANG

STOBER POSIDRIVE ® MDS 5000 installation method

STOBER POSIDRIVE ® MDS 5000 installation method

Core Overview

Product positioning: ST Ö BER fifth generation inverter, used for supplying power to servo motors (MDS series) and asynchronous motors (FDS, MDS series), is a restricted sales product and may require anti-interference measures for residential use.

Target audience: Only qualified personnel who have received professional training are allowed to install, debug, and maintain.

Key signs: including 5 levels of safety signs such as DANGER (fatal risk) and Warning (major risk), which must be strictly followed.

Safety points

(1) Hardware security

High voltage protection: Do not open the casing when live. After power failure, wait for ≥ 5 minutes (DC link discharge) before operating the option board.

Grounding and installation: Protective conductors must be connected and installed vertically only in enclosed switchgear (IP20), avoiding installation above heating equipment at ambient temperatures of 0-45 ° C (overheating requires derating).

Circuit limitation: The motor needs to be equipped with temperature monitoring or overload protection, only copper wire is used, and the wire cross-section meets NEC standards. Objects are prohibited from entering the interior of the equipment.

(2) Software specifications

POSITool software: licensed for use only, can adjust parameters, monitor signals, prohibit reverse compilation or subleasing, ST Ö BER only maintains the latest two program versions.

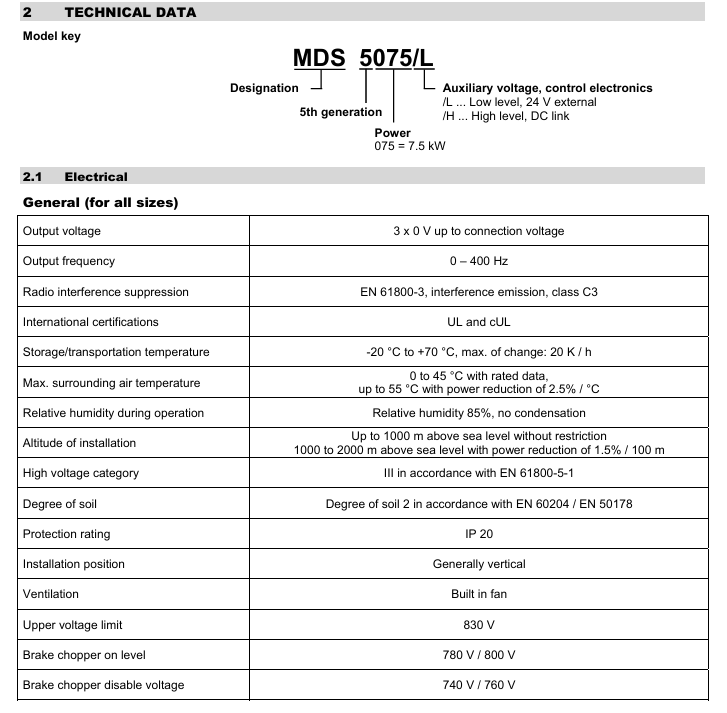

Core technical parameters

(1) General parameters

Parameter Value

Protection level IP20

High voltage category EN 61800-5-1 Class III

Maximum voltage 830V

Brake chopper disabled voltage 740V/760V

Motor cable length ≤ 50m (over 50m requires derating)

(2) Key parameters of specifications (partial)

Recommended specifications: motor power, rated current (servo mode), brake resistor adaptation

BG0 (MDS 5015) 1.5kW 3 × 3.0A 200 Ω (maximum 3.2kW)

BG1 (MDS 5075) 7.5kW 3 × 10A 47 Ω (maximum 13.6kW)

BG3 (MDS 5450) 45kW 3 × 60A 15 Ω (maximum 42kW)

Installation points

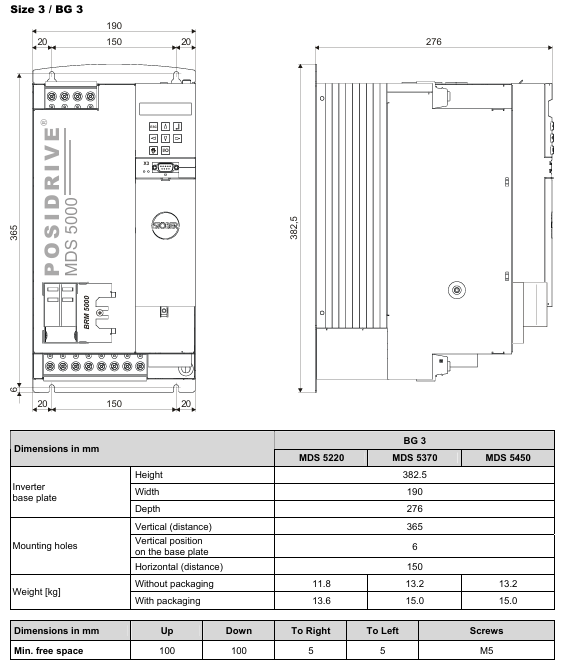

(1) Mechanical installation

Position requirement: Install vertically inside the enclosed switchgear, leaving a minimum free space (100mm up/down, 5mm left/right; 120mm below with EMC shielding board).

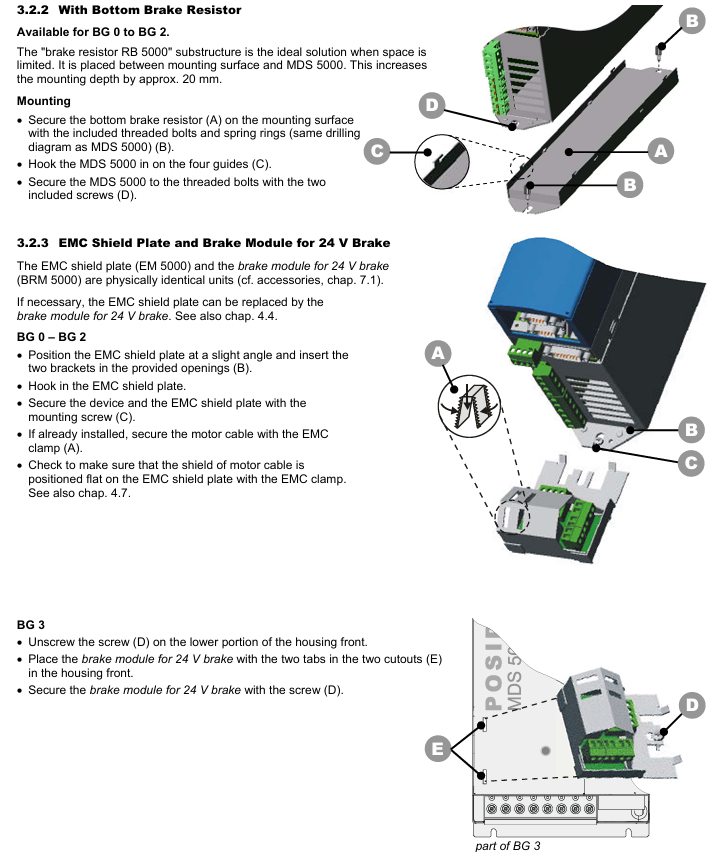

Accessory installation: Before installing the optional modules (fieldbus, I/O terminals), power off and discharge are required, and touching the gold-plated contacts is prohibited; The depth of the bottom braking resistor (RB 5000) is increased by about 20mm, and the EMC shielding board can be replaced with a 24V braking module.

(2) Electrical installation

EMC measures: Separate power lines from signal lines, use shielded wires for motor cables with a large area of shielding layer, and shield brake resistor cables exceeding 30cm.

Power and protection: Use RK1 level fuses (such as Bussmann KTS-R series), and choose 300/500mA or delayed RCD circuit breakers.

DC link coupling: Only three-phase equipment can be coupled, and parameter A38 (set 1 for group 2/3) needs to be set. In case of a fault, the entire power supply needs to be disconnected, and fuses need to be replaced in pairs.

Safe torque shutdown: achieved through the ASP 5001 option, requiring dual shutdown (enable+option), with at least one functional test per month.

Wiring and Connection

Key terminals: X1 (enable), X4 (encoder, no live plugging), X10 (power supply), X20 (motor), X22 (DC link), need to be wired according to pin definitions (such as X4 encoder compatible with EnDat) ®/ HTL/TTL/SSI)。

Example: The BRM 5000 module is used to connect the X300-X302230V brake with a 24V brake, and an interface relay needs to be added. The motor cable should be shielded if it exceeds 300mm.

accessories

(1) Accessories Overview

Accessory Name Part Number Description Remarks

Standard I/O terminal module (SEA 5001) 49576 2 analog inputs (11 bits+symbol), 2 analog outputs (± 10 bits), 5 binary inputs, 2 binary outputs Chapter 3.3.2 of this manual

Extended I/O Terminal Module (XEA 5001) 49015 3 analog inputs (1 15 bit+symbol, 2 11 bit+symbol resolution), 2 analog outputs (± 10 bits), 13 binary inputs, 10 binary outputs, 2 D-SUB 9: Incremental Encoder (TTL) or SSI Input/Output Interface (X20- compatible with SDS 4000) (2 D-SUB 9 with the same function, simplified signal transmission) Chapter 3.3.2 of this manual

X120 SSI connection cable 49482 is used to connect the X120 SSI interface to XEA 5001, Chapter 5.3

Rotary Transformer I/O Terminal Module (REA 5000) 44570 2 analog inputs (1 15 bit+symbol, 1 11 bit+symbol resolution), 2 analog outputs (± 10 bits), 5 binary inputs, 2 binary outputs, 1 D-SUB 9: Rotary Transformer Connection (16 bits), 1 D-SUB 9: Incremental Encoder Simulation (TTL) Chapter 3.3.2 of this manual

EMC shielding board (EM 5000) 44959 motor line shielding connection module, can be added to the basic shell in Chapters 2.2 and 3.2.3 of this manual

The 24V brake module (BRM 5000) 44571 is used to activate the 24V motor holding brake and is delivered together with the EMC shielding board. It can be added to the basic housing in chapters 3.2.3 and 4.4 of this manual

POSISwitch ® Connecting cable (0.5m) 45405-45386 POSISwitch ® To POSIDRIVE ® Connecting cable for AX 5000/MDS 5000 (0.5m, prefabricated)-

POSISwitch ® Connecting cable (2.5m) 44574 POSISwitch ® To POSIDRIVE ® Connection cable for AX 5000/MDS 5000 (2.5m, prefabricated) (DSP402 in preparation)

CANopen DS-301 fieldbus module (CAN5000) 44575 CAN bus coupling Chapter 3.3.1 of this manual, supplementary document: fieldbus/CANopen, document numbers 441684 (German), 441686 (English)

PROFIBUS DP-V1 fieldbus module (DP5000) 49014 PROFIBUS DP-V1 coupling Chapter 3.3.1 of this manual, supplementary document: Fieldbus/PROFIBUS, document numbers 441685 (German), 441687 (English)

EtherCAT Option Module (ECS5000) - Real time Ethernet Link EtherCAT, implemented through CANopen in Chapter 3.3.1 of this manual, supplementary document: Fieldbus/EtherCAT, document numbers 441895 (German), 441896 (English)

EtherCAT cable (0.21m) 49313 CAT5e Ethernet jumper, yellow Chapter 5.3

EtherCAT cable (0.38m) 49314 CAT5e Ethernet jumper, yellow Chapter 5.3

Startup Lock ASP 5001- Only available for installation by ST Ö BER ANTRIEBSTECHNIK, please select Chapter 4.6 at the time of ordering

The product CD "ST Ö BER ELECTRIC 5000" 44989 includes POSITool (PC program for inverter programming, operation, and monitoring), documentation, and fieldbus files that can be accessed from http://www.stoeber.de Download POSITool

G3 connection cable 41488, connecting cable between PC and MDS, with 9-pin sub D plug, socket/plug Chapter 5 (X3- Serial Interface)

USB to RS232 adapter 45616--

The external operator ControlBOX 42224 is an operation unit used for setting and operating inverter parameters, including a 1.5m connection line supported by SV 5.1 and above versions. The ControlBOX documents are numbered 441445 (German), 441479 (English), and 441651 (French); Extra cables: 5m (part number 43216), 10m (part number 43217)

96x96mm DIN housing with built-in external operator 42225 protection level IP54, other functions are the same as above-

(2) Braking resistor

1. FZM (U), FZZM, and VHPR series

Listed are the part numbers, thermal time constants, compatibility with various MDS 5000 models for different types of braking resistors (such as FZM 330x35 250W 300 Ω, FZMU 400x65 600W 100 Ω, etc.), as well as the size parameters (length, diameter, height, mounting hole size, etc.) and weight of the FZM (U)/FZZM (IP20 protection level) and VHPR (IP54 protection level) series.

2. FZT, FZZT, FZDT, and FGFT series

Includes part numbers, thermal time constants, compatibility with MDS 5000 (MDS 5220, MDS 5370, MDS 5450) for various models (such as FZT 400x65 600W 22 Ω, FZZT 400x65 1200W 20 Ω, etc.), as well as size parameters and weights for FZT/FZZT/FZDT and FGFT series.

3. Bottom brake resistor RB 5000

The part numbers, thermal time constants, compatibility with various MDS 5000 models (RB 5022 100W 22 Ω, RB 5047 60W 47 Ω, etc.), dimensional parameters (height x width x depth), drilling drawings (the same as MDS 5000), weight and power cord length, protection level IP54, refer to Chapter 2.2 Dimensional Drawings and Chapter 3.2.2 Mechanical Installation.

(3) Output derating device

1. Technical parameters

Safety warning: Using an output derater beyond the rated data (cable length, current, frequency, etc.) may cause overheating and fire, and should be operated within the rated data range; When the cable length exceeds 50m and ST Ö BER ANTRIEBSTECHNIK cable is not used, the fault assessment of the motor temperature sensor may be affected by the cable capacitance. The wire cores of the motor temperature sensor and the brake need to be separated (with a maximum length of 100m), otherwise it may cause the machine to stop.

|Model | MDB-G0 3x4-3000 (part number 49582) | MDB-G1 3x16-900 (part number 49583) | MDB-G2 3x32-500 (part number 49584)|

|Specifications | BG0 | BG1 | BG2|

|Voltage Range | 3 × 0-500V | Same Left | Same Left|

|Frequency range | 0-150Hz | Same left | Same left|

|Servo motor operation (servo control mode) -8kHz rated current | 3A | 10A | 20A|

|Servo motor operation (servo control mode) -8kHz maximum overload | 250%/2 seconds, 200%/5 seconds | Same left | Same left|

|Servo motor operation (servo control mode) - maximum motor voltage | 1.0kV | same left | same left|

|Servo motor operation (servo control mode) - maximum dU/dt | 3.5kV/μ sec | same left | same left|

|Three phase current motor operation (V/f, VC, SLVC control mode) -4kHz rated current | 4A | 16A | 32A|

|Three phase current motor operation (V/f, VC, SLVC control mode) -4kHz maximum overload | 180%/5s, 150%/30s | Same left | Same left|

|Three phase current motor operation (V/f, VC, SLVC control mode) - maximum motor voltage | 1.4kV | same left | same left|

|Three phase current motor operation (V/f, VC, SLVC control mode) - maximum dU/dt | 3.0kV/μ sec | same left | same left|

|Maximum allowable cable length | 100m | Same left | Same left|

|Output derating temperature | 45 ° C | Same left | Same left|

|Design | Open | Same Left | Same Left|

|Power consumption | 40W | 80W | -|

|Connection method | Screw terminal | Same left | Same left|

|Maximum output derating/mm ² | 4.0 | 6.0 | -|

|Certification | (in preparation) | Same left | Same left|

2. Dimensional parameters

Model L (mm) H (mm) B (mm) N1 (mm) N2 (mm) Ø D (mm) Threaded joint connection (mm ²) Weight [kg]

MDB-G0 3x4-3000 95 110 66 62.5 40 5.8 M5 4 2

MDB-G1 3x16-900 125 160 71 100 55 5 M4 4 3

MDB-G2 3x32-500 155 185 91 130 71 8 M7 16 6

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923