K-WANG

HIMA HIMatrix MI 24 01 Safety Related Controller Module

HIMA HIMatrix MI 24 01 Safety Related Controller Module

Product core positioning

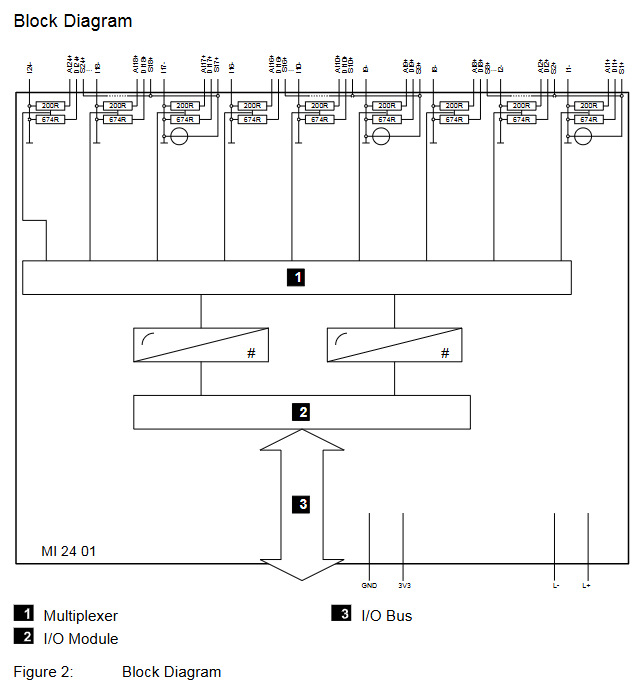

MI 24 01 is a modular safety related input module launched by HIMA (Paul Hildebrandt GmbH+Co KG) in Germany, specifically designed for the HIMatrix F60 modular control system. Its core function is to achieve safe acquisition and fault monitoring of 24 analog or digital signals, suitable for scenarios with high safety requirements such as petrochemical, energy, and process industries (such as SIL 3 safety circuits). The module supports software configuration as analog input (0/4~20 mA current signal) or digital input (proximity switch, safety contact, etc.), with safety features such as fault self diagnosis, signal isolation, overcurrent/overvoltage protection, and complies with international safety standards such as IEC 61508 (SIL 3), EN 954-1 (Cat. 4), and EN ISO 13849-1 (PL e).

Key technical specifications

1. Core input capability

Category specific parameters

The number of input channels is 24, which cannot be used as both analog and digital signals at the same time. It needs to be configured independently for a single channel

Analog Input (AI) - Signal Type: 0/4~20 mA Unidirectional Current Signal

-Input resistance: 200 Ω

-Measurement accuracy: ± 0.2% full range at 25 ℃, ± 0.5% full range over full temperature range

-Resolution: 12 bits

-Sampling time: Approximately 45 μ s per channel, refresh rate synchronized with F60 system cycle

Digital Input (DI) - Compatible with EN 60947-5-6 standard proximity switches, safety proximity switches, contacts with resistance wiring

-Nominal input resistance: 674 Ω

-Short circuit current (proximity switch power supply): 12.2 mA

-Response delay: 2 x F60 cycles in L → H direction, H → L direction needs to be combined with filtering configuration

Power output is divided into 3 independent power supply groups (corresponding to channels 1-8, 9-16, 17-24), with a maximum output current of 200 mA per group. It supports switching between 8.2 VDC/26 VDC and has short-circuit protection (restart after 30 seconds of overload, retry after 60 seconds of continuous overload)

2. Physical and environmental parameters

Range of environmental parameter specifications

Working temperature: 0 ℃~+60 ℃ (normal environment inside industrial control cabinet)

Storage temperature -40 ℃~+85 ℃ (for transportation and inventory scenarios)

Protection level module body IP20 (requires overall protection with F60 cabinet, and additional IP54 enclosure for explosion-proof scenarios)

Altitude limit<2000 meters (no need to downgrade)

Pollution Level II (IEC/EN 61131-2, applicable to minor pollution in industrial environments)

Size and Weight - Size: 6 RU height, 4 HP width (compatible with F60 standard rack)

-Weight: 580 g

The power supply requirement is 24 VDC (-15%~+20% fluctuation), provided by the F60 system power module, with a typical power consumption of 5.5 W (no-load) and a maximum power consumption of 16 W (full load)

3. Safety and Compliance

Specific compliance items of certification standards

Functional Safety Standard - IEC 61508: SIL 3 (Safety Integrity Level)

-EN 954-1: Cat. 4 (safety category)

-EN ISO 13849-1: PL e (performance level)

-ATEX/IECEX: Zone 2 hazardous area adaptation (to meet EN 60079-15 enclosure requirements)

Electromagnetic compatibility (EMC) EN 61000-4-2 (electrostatic discharge), EN 61000-4-5 (surge), EN 55022 (radiated emission Class A)

Electrical Safety IEC/EN 61131-2 (Protection Class III) UL 61010-1、CSA C22.2 No. 61010-1

Core functions and fault handling

1. Signal conditioning and safety monitoring

Filtering and anti-interference: Analog input supports software configuration of low-pass filtering (to suppress high-frequency noise), while digital input can enable "noise blanking" (the signal needs to last for 2 system cycles to be recognized to avoid false triggering by surges, but it will increase response delay);

Fault self diagnosis:

Channel level fault: Monitor open circuit (signal<lower limit value), short circuit (signal>upper limit value), abnormal A/D conversion, measurement value exceeding the safe accuracy range. After triggering, set the corresponding error code and light up the ERR light;

Module level faults: power supply abnormality, data bus fault, temperature exceeding limit (FTT test), triggering to cut off power supply to the fault group and report to the system;

Safety response logic: When there is an analog fault, set AI. Error Code>0. When there is a digital fault, output a low level according to the "power loss trip" principle to ensure that the system enters safe mode in the event of a fault.

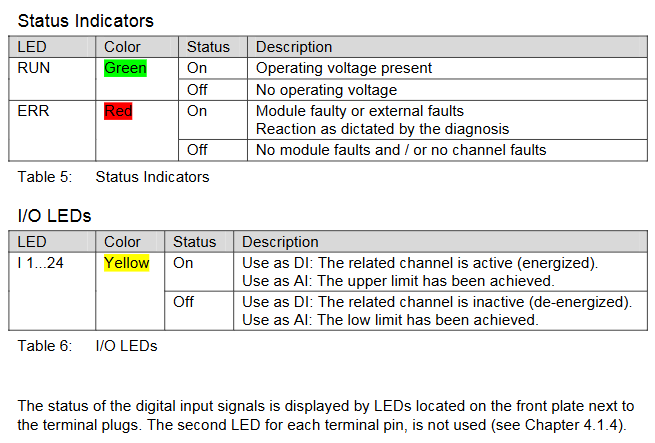

2. Status indication and operation

LED indicator light status and meaning

RUN (green) constantly on: module power supply is normal; Extinguished: No power supply or module failure

ERR (red) constantly on: module or channel failure; Extinguish: No malfunction

I 1-24 (yellow) constantly on (DI mode): channel activated (powered on); Always on (AI mode): Measurement value reaches the upper limit; Extinguished: Channel not activated or reaching lower limit

Installation and Configuration

1. Physical installation

Rack adaptation: Only supports HIMatrix F60 modular rack, installed in slots 3-8 (slot 1 for power module, slot 2 for CPU module);

Installation steps:

Disconnect the system power and remove the cables from the front panel of the rack;

Insert the module along the upper and lower rails of the rack, press the front panel until it clicks into place with the back panel socket;

Fix the upper and lower ends of the module with screws and reconnect the cables;

Explosion proof installation (Zone 2): It needs to be installed in an enclosure with a protection level of IP54 or above, ensuring heat dissipation (maximum power consumption of the module is 16 W), and using PELV/SILV level 24 VDC power supply.

2. Wiring specifications

Cable requirements: Both analog and digital inputs must use shielded twisted pair cables, with the shielding layer grounded at one end (controller side), and a total resistance of ≤ 250 Ω (analog) and ≤ 50 Ω (digital);

Pin allocation: 24 channels are divided into 3 groups, each group of pins including "power supply (Sx+), ground (Ix -), digital input (DIx+), analog input (AIx+)". Example (channels 1-8):

Pin Identification Function Description

A 01 S1+channels 1-8 power output

A 02 I1- Channel 1 Grounding

B 01 DI1+Channel 1 Digital Input

B 02 AI1+Channel 1 Analog Input

3. Software configuration

Tool adaptation:

System firmware<V7: configured using ELOP II Factory;

System firmware ≥ V7: Use SILworX (recommended, supports graphical interface);

Core configuration items:

Channel Type (AI/DI): Single channel independent setting Channel Used [BOOL] (1=enabled, 0=disabled);

Threshold configuration: Limit Value LOW/HIGH (DI mode: effective high and low level range; AI mode: under/over range threshold), Hysteresis LOW/HIGH (DI mode: switching threshold);

Power supply settings: Transmitter Voltage (8.2 V/26 V switching per group), Transmitter Used [BOOL] (whether to use module power supply).

Ordering and matching

1. Core components and spare parts

Component Name Model/Part Number Description

MI 24 01 module 98 2200115 24 channel safety input module (with normal coating, non optional uncoated version)

Two wire transmitter protection module 99 4703202 (H 7032) is compatible with two-wire transmitters and has SIL 3 safety protection

Three wire transmitter protection module 99 4703302 (H 7033) is compatible with three wire transmitters and has SIL 3 safety protection

The terminal plug does not have a clear part number for the module front board wiring terminal, and needs to be ordered separately

2. Documentation and technical support

Essential documents:

《HIMatrix System Manual Compact Systems》(HI 800 141 E);

《HIMatrix Safety Manual》(HI 800 023 E);

SILworX Online Help or ELOP II Factory Online Help;

Technical Support: HIMA Germany Headquarters (Phone+49 6202 709-0, Email) info@hima.com )Or regional agents (such as document provider SDS Automatyka).

Maintenance and lifecycle

Regular maintenance: Conduct precision calibration (analog input) and functional verification (safety circuit proof test) every 10 years;

Fault replacement: After a module failure, it needs to be replaced as a whole (cannot be repaired on site). When replacing, the system power supply needs to be disconnected, and the same model or HIMA certified replacement model should be used;

Scrap disposal: It is necessary to dispose of industrial electronic waste in accordance with the regulations. You can contact HIMA to sign a disposal agreement.

Key precautions

Channel configuration restrictions: 24 channels cannot be mixed into AI/DI mode and must be configured uniformly or grouped;

Power overload protection: Each group can provide a maximum of 200 mA of power. After overload, it will automatically restart within 30 seconds. If the overload persists, it will retry within 60 seconds. It is necessary to avoid connecting too many high-power devices to a single group;

Explosion proof scenario requirements: Zone 2 installation must meet EN 60079-15 enclosure protection (IP54+) and be labeled with "power-off operation only";

Software compatibility: The ELOP II Factory project and SILworX project are non editable, and compatibility needs to be confirmed before upgrading firmware.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923