K-WANG

Teknic SSt-6000-U Digital Servo Drive

Teknic SSt-6000-U Digital Servo Drive

Product core positioning

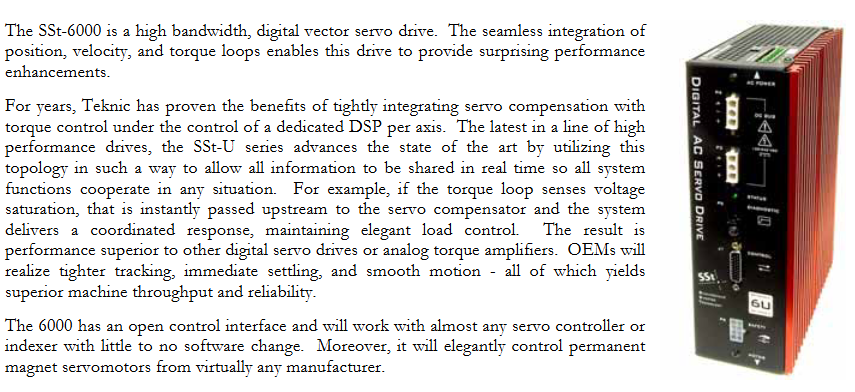

SSt-6000-U is a high bandwidth digital vector servo driver launched by Teknic Corporation in the United States, designed specifically for high-precision motion control scenarios. Its core function is to achieve precise control of the position, speed, and torque of permanent magnet servo motors (including rotary, linear, brushed/brushless, and other types) in three closed loops. It adopts a "dedicated DSP for each axis" architecture, which solves the pain points of traditional servo drives in dynamic response, load adaptation, anti-interference, and other aspects through real-time data sharing and collaborative control algorithms. It is suitable for OEM applications such as machine tools, automated production lines, and precision equipment that require high motion accuracy (such as zero setting time, ultra-low tracking error) and reliability. It can directly replace stepper drives or upgrade traditional servo systems without requiring a large amount of software adaptation.

Key technical specifications

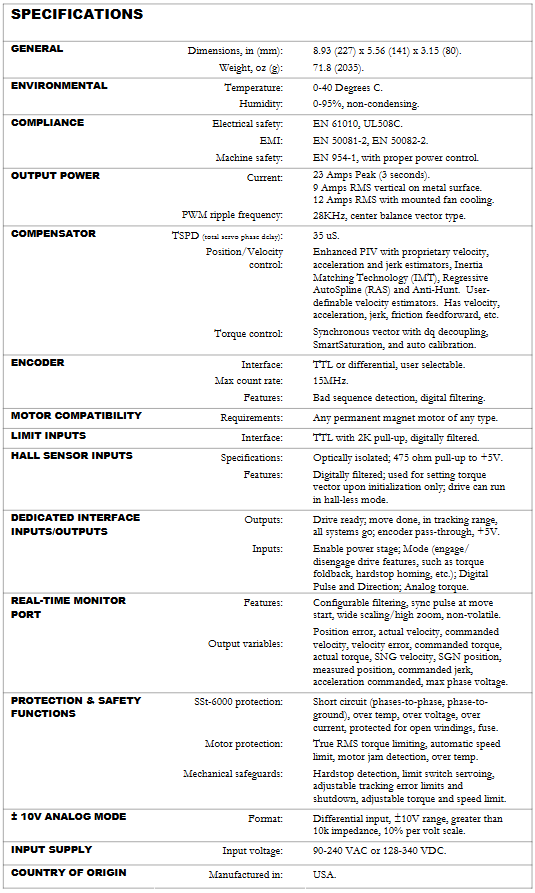

1. Basic and environmental parameters

Physical dimensions and weight - Dimensions: 8.93 x 5.56 x 3.15 inches (227 x 141 x 80 mm)

-Weight: 71.8 ounces (2035 g)

Working environment - Temperature: 0~40 ℃ (no condensation)

-Humidity: 0~95% RH (non condensing)

-Installation: Vertical installation on metal surface (with reserved heat dissipation space)

Compliance - Electrical Safety: EN 61010, UL 508C

-Electromagnetic compatibility (EMC): EN 50081-2 (emission), EN 50082-2 (anti-interference)

-Mechanical safety: EN 954-1 (requires compliant power control)

2. Power output and motor compatibility

Output current - peak current: 23 A (continuous for 3 seconds)

-Rated current: 9 A RMS (vertically installed on metal surface), 12 A RMS (with fan cooling)

PWM characteristics: 28 kHz center balanced vector PWM ripple frequency, reducing motor operating noise and heat generation

Motor compatibility supports almost all manufacturers' permanent magnet motors (without electrical restrictions), including:

-Rotary/linear servo motor, brushed/brushless motor

-Special types such as galvanometer motors and voice coil motors

3. Control performance and algorithms

Total servo phase delay (TSPD) 35 μ s (industry-leading, fully deterministic delay from position feedback reading to motor torque update)

Control closed-loop three loop collaboration (position+speed+torque), supporting:

-Position mode: Tracking error compensation, zero setting time (≤ 1 ms, requiring mechanical bandwidth matching)

-Speed mode: adaptive load inertia, anti resonance

-Torque mode: synchronous vector control, DQ decoupling, SmartSaturation (maintaining control stability when voltage/current saturates)

Core algorithm - IMT (Inertial Matching Technology): Adaptive control based on neural fuzzy logic, eliminating inertia matching concerns and adapting to large/variable inertia loads

-RAS (Regression Automatic Spline): jerk (Acceleration) restricts trajectory planning to reduce impact, vibration, and wear

-Anti Hunt: Small signal sliding mode automatic gain modulation to avoid axis oscillation under high gain conditions

-Multi order feedforward compensation: improves tracking accuracy without the noise and torque jitter of traditional feedforward

4. Feedback and Interface

Encoder Interface - Type: TTL/Differential (User Optional)

-Maximum count rate: 15 MHz

-Function: Fault sequence detection, digital filtering, support for position recovery

Hall sensor interface - isolation: photoelectric isolation, 475 Ω pull-up to+5V

-Function: Used only for torque vector setting during initialization, supports no Hall mode operation

Dedicated I/O interface - Output: Drive ready, motion completed, within tracking range, encoder pass through,+5V power supply

-Input: power level enable, mode selection (torque return, hard limit return to zero, etc.), digital pulse/direction command, analog torque command

Analog input (± 10V) differential input, impedance>10 k Ω, scaling ratio 10%/V, used for simulating torque command input

The real-time monitoring port can be configured with filtering and synchronization pulses, and the output variables include position error, actual/commanded speed, torque, acceleration, maximum phase voltage, etc. It supports non-volatile storage

5. Power Supply and Protection

Input power supply wide voltage adaptation: 90~240 VAC or 128~340 VDC (no need to manually switch voltage levels)

Driver Protection - Electrical Protection: Short Circuit (Phase to Phase/Relative Ground), Over Temperature, Over Voltage, Over Current, Winding Open Circuit Protection, Fuse

-Motor protection: true RMS torque limit, automatic speed limit, motor stalling detection, over temperature protection

Mechanical safety protection hard limit detection, limit switch servo control, adjustable tracking error limit and shutdown, adjustable torque/speed limit

Core functions and advantages

1. High precision motion control capability

Zero setting time: For point-to-point motion scenarios, under the premise of mechanical bandwidth matching, the setting time is ≤ 1 ms, greatly improving device throughput;

Ultra smooth trajectory: RAS technology generates jerk limited motion curves, which can reduce equipment vibration, noise, and mechanical wear even at high speeds;

Anti interference and stability: The Anti Hunt algorithm eliminates shaft oscillations under high gain, ensuring no drift and no loss of accuracy when the shaft is stationary.

2. Flexible integration and ease of use

Plug and play compatibility: The digital trajectory command interface is compatible with most indexes/servo controllers, requiring no or only a small amount of software modification, and can directly replace stepper drivers;

Universal motor control: No manufacturer/type restrictions, supports brushed/brushless, rotary/linear motors, reducing OEM stocking and adaptation costs;

Simplify debugging and maintenance:

Collaborate with Teknic QuickSet ™ Tools that provide mechanical system diagnosis and reduce early failures caused by assembly errors;

Logical power backup (DSP still works when the main power is disconnected), power failure location recovery (no need to reset to zero), to improve equipment fault tolerance and operation efficiency;

Built in cable/sensor fault detection (including intermittent problem capture) simplifies troubleshooting.

3. Safety and reliability

Full scenario protection: multi-layer protection from electrical (overcurrent/overvoltage), motor (stalling/overheating) to mechanical (hard limit/tracking error) to avoid equipment damage;

True RMS torque limit: Compared to traditional I ² t or temperature controllers, it is more precise in preventing motor burnout and does not require additional wiring or sensors;

EMI optimization: QuietDesign ™ The electromagnetic interference suppression system can meet CE certification without the need for shielding clamps or ferrite cores, reducing wiring complexity.

Typical application scenarios

Precision machine tools: zero setting time and high tracking accuracy, suitable for precise control of tool paths;

Automated assembly line: with torque reversal and force control functions, suitable for contact operations such as part insertion and pressing;

Semiconductor equipment: low latency and anti vibration characteristics, meeting high-precision motion requirements such as wafer handling and photolithography;

Alternative stepper system: Directly replace the stepper driver to improve motion smoothness and positioning accuracy without modifying the original controller software.

Product core positioning

SSt-6000-U is a high bandwidth digital vector servo driver launched by Teknic Corporation in the United States, designed specifically for high-precision motion control scenarios. Its core function is to achieve precise control of the position, speed, and torque of permanent magnet servo motors (including rotary, linear, brushed/brushless, and other types) in three closed loops. It adopts a "dedicated DSP for each axis" architecture, which solves the pain points of traditional servo drives in dynamic response, load adaptation, anti-interference, and other aspects through real-time data sharing and collaborative control algorithms. It is suitable for OEM applications such as machine tools, automated production lines, and precision equipment that require high motion accuracy (such as zero setting time, ultra-low tracking error) and reliability. It can directly replace stepper drives or upgrade traditional servo systems without requiring a large amount of software adaptation.

Key technical specifications

1. Basic and environmental parameters

Physical dimensions and weight - Dimensions: 8.93 x 5.56 x 3.15 inches (227 x 141 x 80 mm)

-Weight: 71.8 ounces (2035 g)

Working environment - Temperature: 0~40 ℃ (no condensation)

-Humidity: 0~95% RH (non condensing)

-Installation: Vertical installation on metal surface (with reserved heat dissipation space)

Compliance - Electrical Safety: EN 61010, UL 508C

-Electromagnetic compatibility (EMC): EN 50081-2 (emission), EN 50082-2 (anti-interference)

-Mechanical safety: EN 954-1 (requires compliant power control)

2. Power output and motor compatibility

Output current - peak current: 23 A (continuous for 3 seconds)

-Rated current: 9 A RMS (vertically installed on metal surface), 12 A RMS (with fan cooling)

PWM characteristics: 28 kHz center balanced vector PWM ripple frequency, reducing motor operating noise and heat generation

Motor compatibility supports almost all manufacturers' permanent magnet motors (without electrical restrictions), including:

-Rotary/linear servo motor, brushed/brushless motor

-Special types such as galvanometer motors and voice coil motors

3. Control performance and algorithms

Total servo phase delay (TSPD) 35 μ s (industry-leading, fully deterministic delay from position feedback reading to motor torque update)

Control closed-loop three loop collaboration (position+speed+torque), supporting:

-Position mode: Tracking error compensation, zero setting time (≤ 1 ms, requiring mechanical bandwidth matching)

-Speed mode: adaptive load inertia, anti resonance

-Torque mode: synchronous vector control, DQ decoupling, SmartSaturation (maintaining control stability when voltage/current saturates)

Core algorithm - IMT (Inertial Matching Technology): Adaptive control based on neural fuzzy logic, eliminating inertia matching concerns and adapting to large/variable inertia loads

-RAS (Regression Automatic Spline): jerk (Acceleration) restricts trajectory planning to reduce impact, vibration, and wear

-Anti Hunt: Small signal sliding mode automatic gain modulation to avoid axis oscillation under high gain conditions

-Multi order feedforward compensation: improves tracking accuracy without the noise and torque jitter of traditional feedforward

4. Feedback and Interface

Encoder Interface - Type: TTL/Differential (User Optional)

-Maximum count rate: 15 MHz

-Function: Fault sequence detection, digital filtering, support for position recovery

Hall sensor interface - isolation: photoelectric isolation, 475 Ω pull-up to+5V

-Function: Used only for torque vector setting during initialization, supports no Hall mode operation

Dedicated I/O interface - Output: Drive ready, motion completed, within tracking range, encoder pass through,+5V power supply

-Input: power level enable, mode selection (torque return, hard limit return to zero, etc.), digital pulse/direction command, analog torque command

Analog input (± 10V) differential input, impedance>10 k Ω, scaling ratio 10%/V, used for simulating torque command input

The real-time monitoring port can be configured with filtering and synchronization pulses, and the output variables include position error, actual/commanded speed, torque, acceleration, maximum phase voltage, etc. It supports non-volatile storage

5. Power Supply and Protection

Input power supply wide voltage adaptation: 90~240 VAC or 128~340 VDC (no need to manually switch voltage levels)

Driver Protection - Electrical Protection: Short Circuit (Phase to Phase/Relative Ground), Over Temperature, Over Voltage, Over Current, Winding Open Circuit Protection, Fuse

-Motor protection: true RMS torque limit, automatic speed limit, motor stalling detection, over temperature protection

Mechanical safety protection hard limit detection, limit switch servo control, adjustable tracking error limit and shutdown, adjustable torque/speed limit

Core functions and advantages

1. High precision motion control capability

Zero setting time: For point-to-point motion scenarios, under the premise of mechanical bandwidth matching, the setting time is ≤ 1 ms, greatly improving device throughput;

Ultra smooth trajectory: RAS technology generates jerk limited motion curves, which can reduce equipment vibration, noise, and mechanical wear even at high speeds;

Anti interference and stability: The Anti Hunt algorithm eliminates shaft oscillations under high gain, ensuring no drift and no loss of accuracy when the shaft is stationary.

2. Flexible integration and ease of use

Plug and play compatibility: The digital trajectory command interface is compatible with most indexes/servo controllers, requiring no or only a small amount of software modification, and can directly replace stepper drivers;

Universal motor control: No manufacturer/type restrictions, supports brushed/brushless, rotary/linear motors, reducing OEM stocking and adaptation costs;

Simplify debugging and maintenance:

Collaborate with Teknic QuickSet ™ Tools that provide mechanical system diagnosis and reduce early failures caused by assembly errors;

Logical power backup (DSP still works when the main power is disconnected), power failure location recovery (no need to reset to zero), to improve equipment fault tolerance and operation efficiency;

Built in cable/sensor fault detection (including intermittent problem capture) simplifies troubleshooting.

3. Safety and reliability

Full scenario protection: multi-layer protection from electrical (overcurrent/overvoltage), motor (stalling/overheating) to mechanical (hard limit/tracking error) to avoid equipment damage;

True RMS torque limit: Compared to traditional I ² t or temperature controllers, it is more precise in preventing motor burnout and does not require additional wiring or sensors;

EMI optimization: QuietDesign ™ The electromagnetic interference suppression system can meet CE certification without the need for shielding clamps or ferrite cores, reducing wiring complexity.

Typical application scenarios

Precision machine tools: zero setting time and high tracking accuracy, suitable for precise control of tool paths;

Automated assembly line: with torque reversal and force control functions, suitable for contact operations such as part insertion and pressing;

Semiconductor equipment: low latency and anti vibration characteristics, meeting high-precision motion requirements such as wafer handling and photolithography;

Alternative stepper system: Directly replace the stepper driver to improve motion smoothness and positioning accuracy without modifying the original controller software.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923