K-WANG

GE Multilin MIF series digital feeder relay

MIF-P type: three-phase+grounding protection relay, suitable for comprehensive protection of three-phase distribution circuits;

MIF-N type: single-phase or ground protection relay, focusing on single-phase circuit or ground fault special protection.

GE Multilin MIF series digital feeder relay

Product basic positioning and core applications

1. Product type and positioning

The MIF series belongs to the M Family (M series) digital feeder relay, which is divided into two core models according to the protected object:

MIF-P type: three-phase+grounding protection relay, suitable for comprehensive protection of three-phase distribution circuits;

MIF-N type: single-phase or ground protection relay, focusing on single-phase circuit or ground fault special protection.

2. Core application scenarios

Main protection: Main circuit protection for various voltage levels of distribution networks, covering lines, distribution equipment, etc;

Backup/auxiliary protection: Backup protection for transformers, generators, and motors to compensate for blind spots in main protection;

Control and Monitoring: Cooperate with circuit breakers to achieve remote control, while providing electrical parameter measurement and equipment status monitoring.

Core functions and technical features

1. Protection function (core highlight)

The MIF series focuses on "overcurrent protection" and is equipped with various specialized protections to adapt to different fault scenarios

(1) Overcurrent protection (TOC/IOC)

Protection type applicable model key parameters and characteristics

Phase TOC MIF-P (three-phase), MIF-N (single-phase) - Setting range: 0.1-2.4 times rated current (I n)

-Curve selection: 4 standard curves (corresponding to ANSI/IEC)+1 user-defined curve, supporting time multiplier adjustment

-ANSI corresponds to IEC curves: Normal Inverse Time (ANSI) → IEC A, Extraordinary Inverse Time → IEC B, Extreme Inverse Time → IEC C, Timed Limit → Timed Limit

Ground TOC MIF-P (standard), MIF-N (optional) - Curve and parameter settings for in-phase overcurrent protection

-Grounding signal acquisition: By default, the residual current of three-phase CT is summed up (without the need for additional sensors); Sensitive scenes can be paired with zero sequence grounded CT (surrounding three-phase conductors) to improve detection accuracy

Instantaneous Overcurrent (IOC) Full Model - Independent Configuration: MIF-P includes 2 sets of three-phase IOC+2 sets of grounded IOC, MIF-N includes 2 sets of single-phase/grounded IOC

-Setting range: pickup (0.1-30 times I n), delay (0-100 seconds), supports individual enable/disable

(2) Other special protections

Thermal Image Protection: prevents equipment from being damaged due to overload and overheating, with a constant heating time

T1 (adjustable from 3-600 minutes), cooling time constant T2 (adjustable from 1-6 times T1), suitable for different device heat dissipation characteristics;

Cold Load Pickup (optional): Automatically adjust the overcurrent setting value when powering on again to avoid triggering the protection by overload current;

Breaker Failure Protection (optional): The basic function is to detect that the circuit breaker has not been opened; Complex solutions can be implemented through digital inputs and configurable output logic (logic gates, timers);

Breaker Health Monitoring (optional): Users set a cumulative current threshold, triggering an alarm when the threshold is exceeded, achieving "on-demand maintenance".

2. Control and operation functions

Circuit breaker control: supports circuit breaker opening/closing operations, triggered by programmed output terminals, and verified by digital input terminals to ensure successful operation;

Two Settings Groups: Two sets of protection parameters can be pre-set to adapt to different operating conditions (such as normal load/peak load);

On site upgrade: Designed with Flash Memory, it supports firmware upgrade through communication or software on-site, without the need to disassemble the device.

3. Monitoring and metering functions

Event recording: Store 32 event records, record key events such as faults and operations, for easy fault tracing;

Waveform recording: supports analog/digital waveform recording, captures instantaneous changes in electrical parameters during faults, and assists in fault analysis;

Dual end metering: CT transformation ratio can be set, and the primary and secondary current measurement values can be monitored simultaneously to meet the data requirements of operation and maintenance.

4. Hardware and interface characteristics

Power adaptation: Supports AC/DC universal power supply, covering 24-48V DC/AC, 110-250V DC, 110-230V AC (specific range see ordering parameters);

Communication interface: Front end RS232 port (local debugging), back-end RS485 port (remote communication), both support ModBus ® RTU protocol, with a maximum speed of 19200 bps;

I/O configuration: comes standard with 2 digital inputs and 6 relay outputs (4 programmable), and can customize output logic (OR/NOT combination) through M+PC software;

Mechanical structure: Drawout case for easy maintenance; Compatible with M-series 19 inch half rack/full rack installation, compatible with system integration.

5. Software and user interaction

Configuration software: supports M+PC software (parameter settings, status monitoring), enerVista.com platform (remote management, see page 275 of the document for details);

Local operation: Front panel buttons for direct parameter adjustment and status viewing;

Indicator lights (LEDs): LED indicator lights can be configured to visually display the device's operating status and fault type.

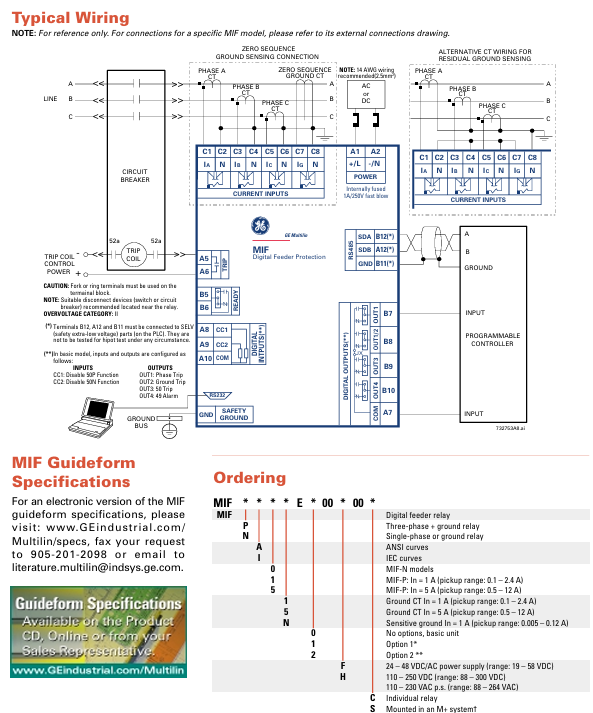

Wiring and safety regulations

1. Typical wiring reference

Grounding detection wiring: Two options are available - ① Three phase CT residual current summation (no additional sensors required); ② Zero sequence grounding CT (sensitive detection scenario);

Current input: It is recommended to use a 14 AWG (2.5mm ²) wire, and the terminal should be a fork or ring terminal;

Safe grounding: It is necessary to connect to a safe ground. Terminals B12, A12, and B11 are only for connecting SELV (safety extra low voltage) components (such as PLC), and withstand voltage testing is prohibited.

2. Safety Tips

Overvoltage category: Class II, suitable disconnect devices (switches or circuit breakers) need to be installed near the relay;

Internal fuse: The power circuit is equipped with a 1A/250V fast fuse to protect the equipment in case of malfunction.

Ordering information (model coding rules)

The MIF series model code format is * * MIF * * * * E * 00 * 00 * * *, and the meanings of the characters in each position are as follows, which need to be combined according to actual needs:

Encoding Position Optional Character Meaning Explanation

1st to 3rd digit MIF product identification (digital feeder relay)

The 4th P/N P=three-phase+grounding relay; N=single-phase or grounded relay

5th A/I A=ANSI standard curve; I=IEC standard curve

6th position 0/1/5=MIF-N type; 1=MIF-P type (I n=1A, setting range 0.1-2.4A); 5=MIF-P type (I n=5A, setting range 0.5-12A)

7th position 1/5/N grounding CT rated current: 1=1A (0.1-2.4A); 5=5A(0.5-12A); N=sensitive grounding (1A, 0.005-0.12A)

8th position (empty)/1/2 empty=base model (no options); 1=Option 1 (configurable I/O, event logging, recording); 2=Option 2 (including option 1 function+cold load input, circuit breaker failure/health monitoring, configurable logic)

The power specifications for positions 9-10 are 24-48V DC/AC (19-58V DC); 110-250V DC(88-300V DC); 110-230V AC(88-264V AC)

The installation method for positions 11-12 is empty=independent relay; M+=Installed on M+system (requires additional order of M050 half 19 inch rack or M100 full 19 inch rack, provided free of charge according to the number of relays)

Example

MIF P A 1 1 2 110: Three phase+grounding relay (P), ANSI curve (A), phase CT I n=1A (1), grounding CT I n=1A (1), including option 2 function (2), 110-250V DC power supply (110).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923