K-WANG

Welker Bearing Linear Guides and Wedge Components

Linear Slides: Achieve smooth and precise linear reciprocating motion of equipment components, undertaking dual functions of guidance and load-bearing;

Gib Assemblies: Used in conjunction with linear guides to adjust guide clearance, compensate for wear, improve motion accuracy and stability, and some models can be used independently as guide components.

Welker Bearing Linear Guides and Wedge Components

Product basic positioning and core application areas

1. Product category and positioning

The linear guide and wedge components of Welker Bearing are both high-precision linear motion parts, with the core positioning being:

Linear Slides: Achieve smooth and precise linear reciprocating motion of equipment components, undertaking dual functions of guidance and load-bearing;

Gib Assemblies: Used in conjunction with linear guides to adjust guide clearance, compensate for wear, improve motion accuracy and stability, and some models can be used independently as guide components.

2. Core application scenarios

Both types of products focus on the demand for "high-precision linear motion" in the industrial field, and typical application equipment includes:

Machine tools: worktable guidance for lathes, milling machines, grinders, and machining centers;

Automation equipment: robot guide rails, automated production line conveyor mechanisms, precision positioning platforms;

Heavy industrial equipment: linear moving parts of metallurgical machinery, heavy-duty presses, and mining equipment;

Special equipment: precision guide rails for aerospace component processing equipment and medical imaging equipment (such as CT and MRI).

Product details of Linear Slides

1. Product series classification

According to the structure, load-bearing capacity, and accuracy level, linear guides are divided into multiple standard series. The core series and characteristics are as follows:

Series name, structural characteristics, core advantages, applicable scenarios

Standard Linear Slides single/double track structure, using steel guide rails and sliders, with built-in lubrication grooves for strong versatility, moderate cost, easy installation, universal machine tools, and lightweight automation equipment

Heavy Duty Linear Slides: Thickened guide rail walls, reinforced slider materials (high carbon steel/alloy steel), multiple sets of rolling elements (or sliding friction pairs) with strong load-bearing capacity (static load can reach several tons), good impact resistance. Heavy duty machine tools, metallurgical machinery, and press machines

Precision Linear Slides (Precision Series) guide rail surface precision grinding (roughness Ra ≤ 0.8 μ m), adjustable clearance, equipped with position feedback interface (optional), high motion accuracy (positioning error ≤ 0.01mm/m), good repeatability Precision machining equipment, medical equipment, aerospace parts processing

Custom Linear Slides can adjust the length of guide rails, number of sliders, installation hole positions, and material (such as stainless steel) according to customer needs to adapt to special installation spaces and working conditions. Non standard equipment and customized scenarios for special industries can also be used

2. Key technical parameters (general standards)

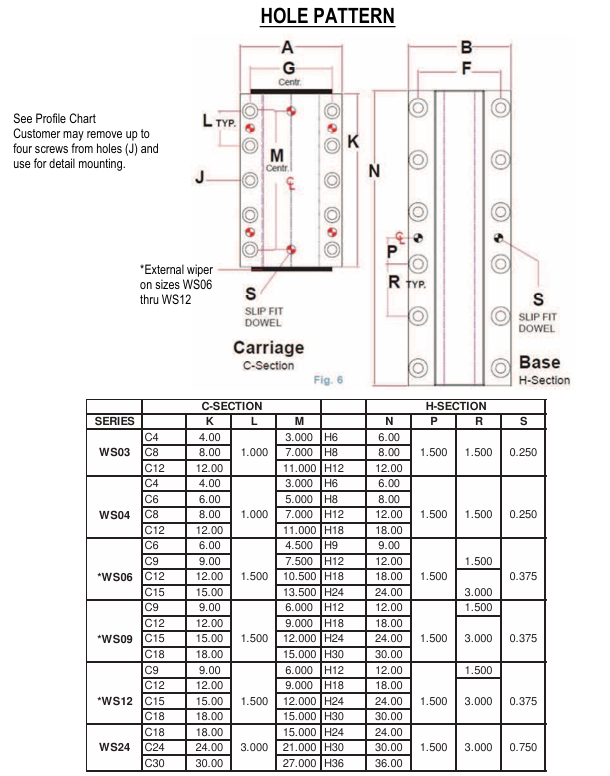

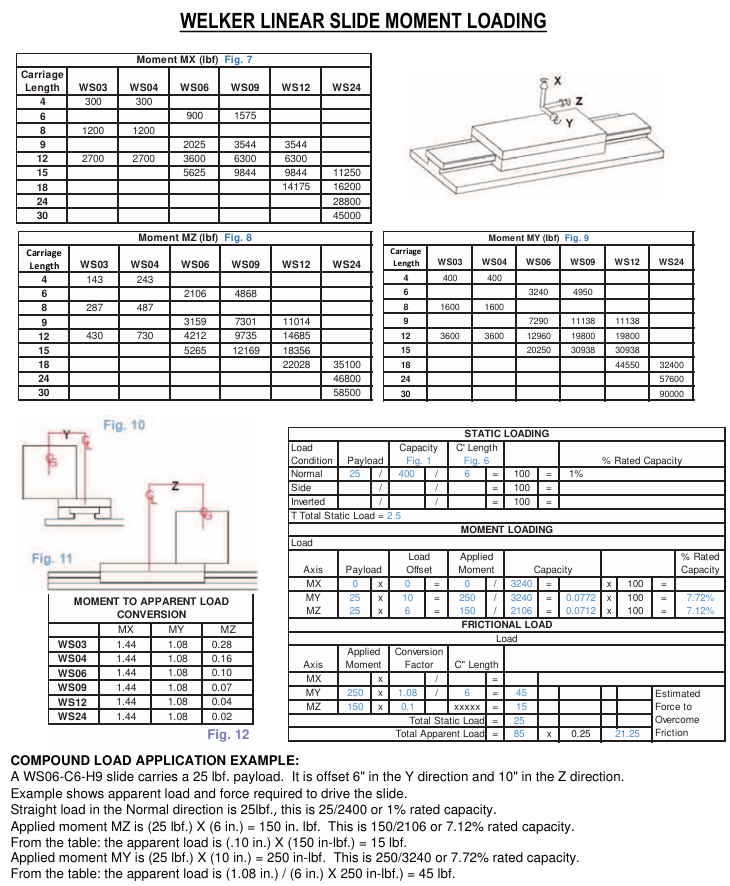

(1) Dimensions and installation parameters

Guide rail length: Standard series 6 inches (152.4mm) -10 feet (3048mm), custom series can be extended to 20 feet (6096mm) or more;

Guide rail cross-sectional dimensions: standard width of 1.5 inches (38.1mm) -6 inches (152.4mm), height adapted to load-bearing capacity (1 inch -4 inches);

Installation method: Bottom/side bolt fixation, standard installation hole spacing of 12 inches (304.8mm), customizable hole distribution.

(2) Performance parameters

Performance Index Standard Series Heavy duty Series Precision Series

Maximum Static Load Capacity: 500-2000 lbf (2.22-8.89 kN) 2000-10000 lbf (8.89-44.48 kN) 800-3000 lbf (3.56-13.34 kN)

Maximum rated dynamic load capacity: 300-1500 lbf (1.33-6.67 kN) 1500-8000 lbf (6.67-35.59 kN) 500-2500 lbf (2.22-11.12 kN)

Position Accuracy ± 0.005 inches/foot (± 0.42mm/m) ± 0.01 inches/foot (± 0.84mm/m) ± 0.001 inches/foot (± 0.084mm/m)

Maximum Speed: 500 inches/minute (12.7m/min), 300 inches/minute (7.62m/min), 800 inches/minute (20.32m/min) (compatible with precision drives)

(3) Material and Protection

Material of guide rail/slider: Standard material is 1045 high carbon steel (quenched hardness HRC 58-62), precision series can choose 440C stainless steel (rust proof), heavy-duty series can choose alloy structural steel;

Surface treatment: The standard is blackening treatment (rust prevention), optional chrome plating (enhanced wear resistance), zinc plating (corrosion resistance, suitable for humid environments);

Lubrication: Built in lubrication groove, supports regular lubrication grease (lithium based grease is recommended), and some models can choose automatic lubrication interface.

Gib Assemblies Product Details

1. Product type and structure

Wedge components, as the "precision compensation and clearance control components" of linear guides, are mainly divided into two categories:

Type Name Structure Composition Core Functions

Solid Gibbs integrated wedge block (inclined angle 3 ° -10 °), fixing bolt, and locating pin are used to fix the guide rail clearance, suitable for scenarios with low wear and stable working conditions

Adjustable Gibs: Split wedge block (active wedge+passive wedge), adjusting bolt (top screw/pull rod), locking nut can adjust the gap in real time (compensating for wear or assembly errors), suitable for high-precision or high wear working conditions

2. Key technical parameters

Material: Same linear guide rail, mainly made of 1045 high carbon steel (quenched HRC 55-60), optional stainless steel;

Slope accuracy: Slope angle tolerance ± 0.5 °, surface roughness Ra ≤ 1.6 μ m;

Adjustment range: The gap adjustment of the adjustable wedge block is 0.001-0.01 inches (0.025-0.254mm), meeting different precision compensation requirements;

Adaptive guide rail: It can be matched with Welker's full range of linear guides, and can also be customized according to the customer's existing guide rail size (a cross-sectional view of the guide rail is required).

Customized services and design support

1. Customized service scope

Welker Bearing provides comprehensive customized solutions, with core customization content including:

Customization of dimensions: rail length, cross-sectional dimensions, installation hole positions/quantities;

Material and surface treatment customization: stainless steel material (rust proof), special alloy (high temperature/corrosion resistance), customized surface coating (such as PTFE coating for friction reduction);

Function customization: Add position sensor interface (such as grating ruler installation slot), integrate dust cover (anti debris/dust), design special lubrication system (automatic lubrication);

Adaptability customization: Design non-standard wedge components or rail structures based on the installation space and load-bearing requirements of the customer's existing equipment rails.

2. Design support services

Technical consultation: Provide linear motion scheme evaluation to assist customers in selecting suitable product series;

Drawing support: Provide 2D (CAD)/3D (SolidWorks) model drawings for customers to integrate into equipment design;

Sample production: Customized products can provide sample testing (sample fee required, refundable after bulk order);

Installation guidance: Provide installation manuals and videos, and if necessary, dispatch engineers to provide on-site guidance for installation.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923