K-WANG

GE MLJ synchronous inspection relay

GE MLJ synchronous inspection relay

Product Overview

Core functions

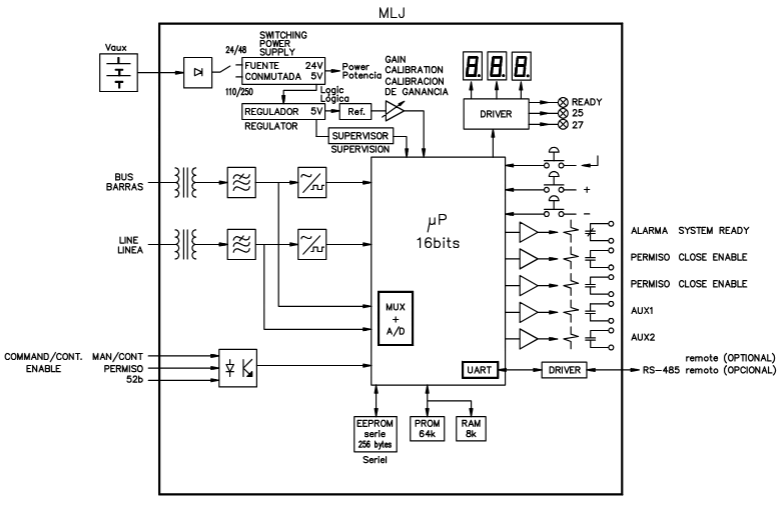

MLJ is a digital synchronous inspection relay mainly used to detect the synchronization conditions of two electrical systems (such as the generator and the power grid, and the two sections of the power grid). By measuring the voltage difference (Δ V), frequency slip (Δ f), and phase angle difference (Δθ) between the bus voltage (VB) and the line voltage (VL), it determines whether the circuit breaker closing conditions are met and outputs a closing permission signal.

Typical application scenarios

Generator and system grid connection

Reconnect the two regions of the system

Manual closing or automatic reclosing of circuit breakers

Verify synchronization conditions to avoid equipment damage caused by asynchronous closing

Core functions and working principles

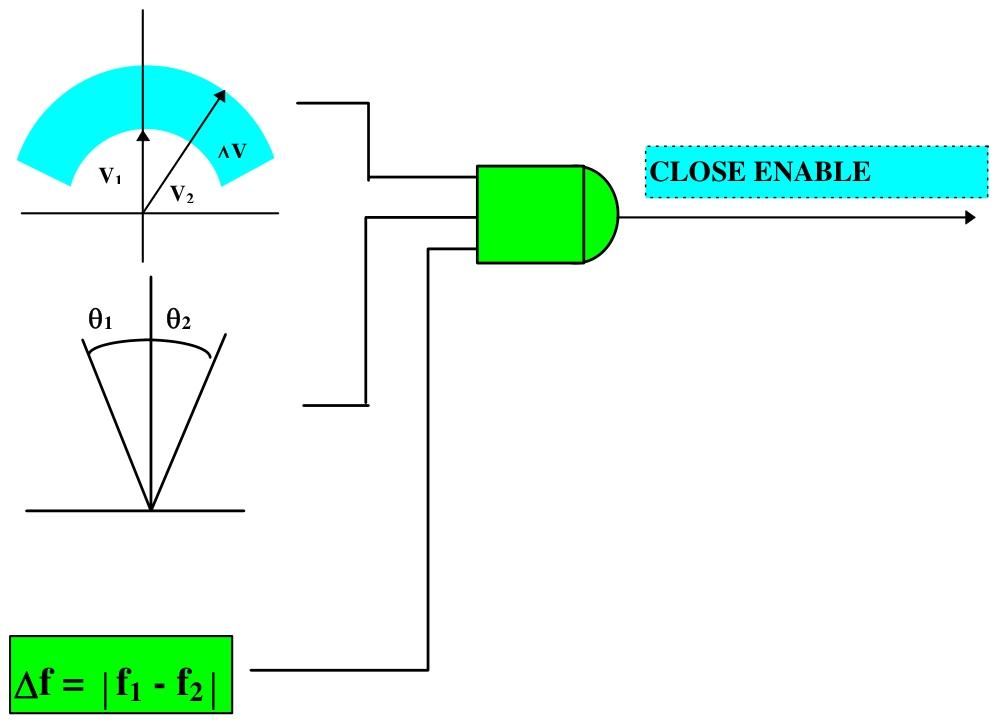

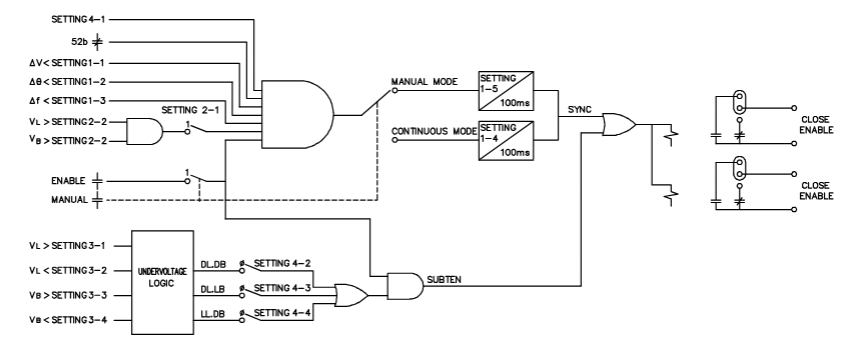

1. Synchronous inspection unit

Measurement parameters:

Voltage difference (Δ V): The absolute difference in voltage between the bus and the line, ranging from 2-90V (default 15V).

Phase angle difference (Δ θ): The phase difference between two voltages, ranging from 2-60 ° (default 10 °).

Frequency slip (Δ f): The frequency difference between two voltages, ranging from 10-500MHz (default 20mHz).

Working mode:

Continuous mode: Continuous monitoring of synchronization conditions, with a delay of 0.1-99.0s (default of 0.1s) before allowing the output to close.

Manual mode: Monitoring is triggered by external signals, and after a delay of 0.1-99.0s (default 10.0s), the output allows for closing.

Allowable conditions for closing: Δ V, Δ θ, and Δ f are all less than the set values and continuously meet the set delay.

2. Undervoltage unit

Independently monitor the voltage status (live/dead) of lines and busbars, supporting three combination modes:

DLDB (Loss of Line - Loss of Power Bus)

DLLB (Lost Line - Live Bus)

LLDB (Live Line - Dead Bus)

Voltage thresholds can be set: line/bus live threshold (VL ↑/VB ↑, 40-245V), and power-off threshold (VL ↓/VB ↓, 10-180V).

3. Input/output unit

Digital input: 3-channel DC input, including circuit breaker status (allowing synchronous check when open), manual mode trigger, and enable signal.

Output contacts: 5-way relay contacts, including 2-channel closing permission (default normally open), 1-channel alarm (default normally closed), and 2-channel configurable auxiliary contacts (supporting signal outputs such as synchronization, undervoltage, and power loss).

4. Self check and Communication

Continuously monitor memory (ROM/RAM/EEPROM), analog circuits, etc., output alarms and display error codes when faults occur (e.g. 8.0 indicates ROM failure).

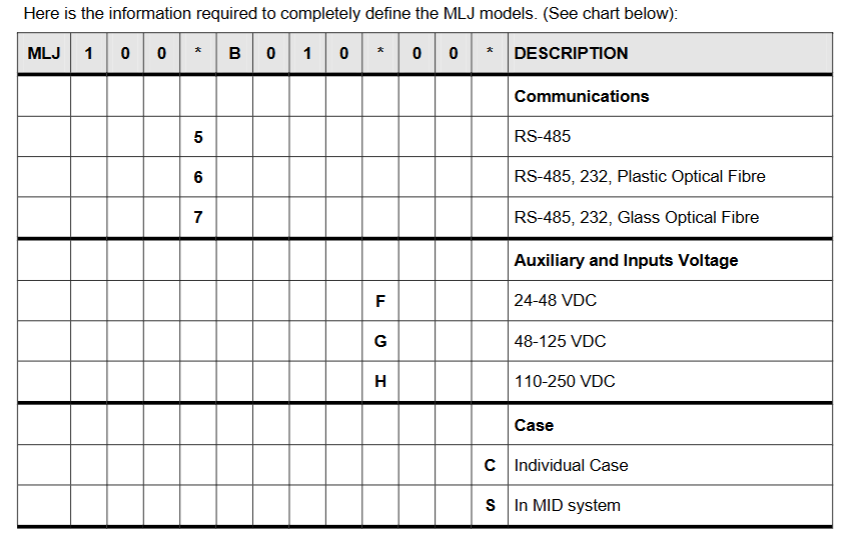

Supports RS-485 communication (optional fiber optic interface), baud rate 0.3-38.4kbaud (default 9.6kbaud), and supports Modbus protocol.

Technical specifications

Electrical parameters

Rated voltage: 63-220Vac (continuous withstand 440Vac).

Auxiliary power supply: 24-48Vdc, 48-125VDC, 110-250Vdc (± 20% fluctuation).

Measurement accuracy: Voltage ± 2% or 0.5V; Angle ± 1 ° (at 20-220Vac); Frequency slip ± 5mHz.

Contact capacity: Closing allows contact 4000VA (maximum 440Vac/300Vdc), auxiliary contact 1760VA.

Environmental and Physical Characteristics

Working temperature: -25 ° C to+55 ° C, storage temperature: -40 ° C to+70 ° C.

Humidity: ≤ 95% (no condensation).

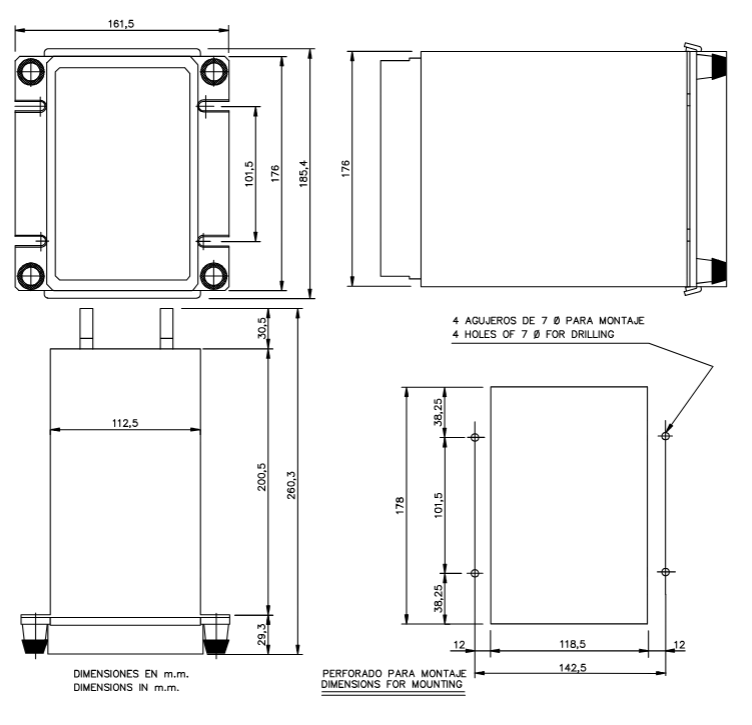

Shell: Made of steel plate material, supporting panel installation or MID system integration, weighing approximately 3kg.

Operation interface and navigation

1. Front end devices

Button: Three vertically arranged buttons, from top to bottom, are ENTER (confirm/enter),+(add/next), and - (decrease/previous).

Display: A 3-digit 7-segment LED display screen used to show parameter values, status codes, and settings.

Indicator lights: 3 LED indicator lights, namely:

READY (green): The relay is ready and the protection function is enabled.

52 (red): The conditions for closing are met.

27 (red): The undervoltage condition is met.

2. Switching between working modes

Reading mode: default power on mode, displaying real-time data and status. Press ENTER to cycle through the various functional items (F0-F12).

Setting mode: In read mode, press ENTER and - simultaneously to enter and modify parameters. After setting up, press+and - simultaneously to return to read mode; If there is no operation for 2 minutes, it will automatically return.

Calibration mode: In reading mode, press ENTER and+simultaneously to enter and display the average values of line voltage and bus voltage for calibration.

Read mode function (F0-F12)

The main functions of cycling through the ENTER key include:

Functional code description

The F0 relay status displays a two digit error code (such as 0.0 indicating normal, 8.0 indicating ROM fault), with the decimal point constantly lit to distinguish the status from the numerical value.

Real time display of RMS voltage value in V for F1-F2 line voltage (VL)/bus voltage (VB).

F3 voltage difference (Δ V) displays the absolute difference between VL and VB, measured in V.

F4 phase angle difference (Δ θ) displays the phase difference between two voltages (0-180 °), and overflow (three horizontal lines) is displayed when the voltage is less than 9V.

F5 frequency slip (Δ f) displays the frequency difference in mHz, and overflow is displayed when the voltage is less than 9V.

Record and store the VL, VB, Δ V, Δ θ, and Δ f values when the last closing condition is met for F6-F10.

The F11 test function display screen is fully lit and flashing, and the LED lights up simultaneously to verify the hardware's normal operation; When the digital input is activated, the corresponding LED flashes.

The F12 line/bus status is indicated by the upper and lower segments of the display screen: the upper segment is lit up to indicate "live", the lower segment is lit up to indicate "power-off", and the middle segment is lit up to indicate that the voltage is between the threshold values.

Set mode parameter configuration

After entering the setting mode, switch the setting items with the+/- keys, press ENTER to enter the modification, and press ENTER again to confirm after adjustment. The main settings are as follows:

1. Basic configuration (0-1, 6-1, 6-2)

0-1 frequency: Choose 50Hz or 60Hz (default 50Hz).

6-1 Communication Address: Set Modbus address (1-255, default 1).

6-2 baud rate: Select the communication rate (0.3-38.4kbaud, default 9.6kbaud).

2. Synchronize check parameters (1-1 to 2-2)

1-1 voltage difference (Δ V): 2-90V (step size 0.5V, default 15V).

1-2 phase angle difference (Δ θ): 2-60 ° (step size 1 °, default 10 °).

1-3 frequency slip (Δ f): 10-500MHz (step size 10mHz, default 20mHz).

1-4 continuous mode delay: 0.1-99.0s (step size 0.1s, default 0.1s).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923