K-WANG

Watlow MLS300 Series Controller

Watlow MLS300 Series Controller

Product basic positioning and core features

1. Product positioning

The MLS300 series is a multi loop PID controller, available in two versions: 16 loop (MLS316) and 32 loop (MLS332), supporting thermocouples RTD、 Multiple sensor inputs such as linear voltage/current and pulse can achieve independent or linked control of process parameters such as temperature, pressure, and flow rate. The system adopts a modular design, compatible with multiple expansion modules (such as DAC/SDAC analog output modules), supports EIA/TIA-232/485 serial communication, can be connected to upper computer or PLC systems, and complies with CE and UL standards ®/ C-UL ® Certification and EU EMC Directive (EN 61326).

2. Core advantages

Advantages Category Specific Characteristics Value Explanation

Multi loop control single device supports 16/32 independent PID loops, each loop can be configured with heating/cooling dual outputs to reduce the number of devices, reduce panel space occupation, and adapt to multi zone process scenarios (such as multi-stage extruders and large ovens)

Flexible input compatibility supports J/K/T/S/R/B/E type thermocouples, 100 Ω platinum RTD (2/3 wire system), 0-20mA/4-20mA current, 0-12V voltage, and pulse input (up to 2kHz) to reduce spare parts inventory and adapt to sensor requirements of different processes without the need for additional signal conversion modules

Advanced control function supports cascade control, proportional control, remote simulation set point, and differential control (enhanced firmware); Ramp/Soak batch control (optional firmware) to meet complex process requirements (such as temperature pressure linkage in chemical reaction vessels, staged temperature control for material aging testing)

High reliability built-in sensor fault detection (open circuit/short circuit/reverse connection), power failure protection, CPU watchdog; Supports storing and calling 8 job programs to shorten troubleshooting time, avoid process abnormalities, and adapt to switching between multiple varieties and small batch production

System composition and hardware architecture

1. List of core components

Component Name, Model/Specification, Function and Function

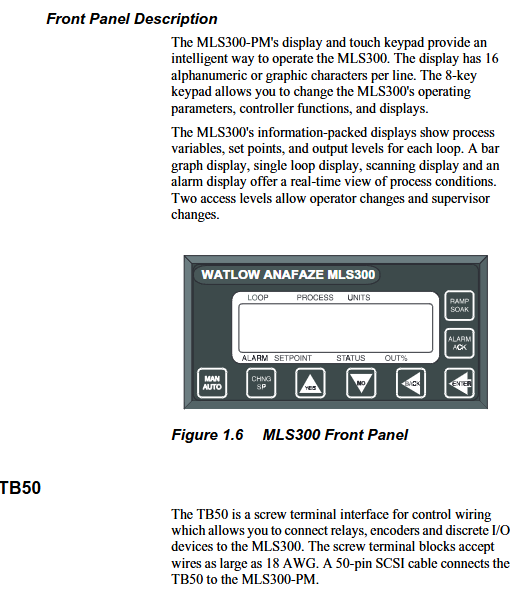

Processor module (PM) MLS300-PM system core, including CPU, 2-line 16 character fluorescent display screen, 8-key keyboard, responsible for data calculation, loop control, and communication management

The Analog Input Module (AIM) MLS300-AIM-16 (16 channels)/AIM-32 (32 channels) receives sensor signals, completes signal conditioning and A/D conversion, and communicates with the processor module through RJ45 cables

Compact Input Module (CIM) CIM316 (16 channels)/CIM332 (32 channels) high-density input module, using D-Sub 50 connector to reduce installation space and adapt to high integration scenarios

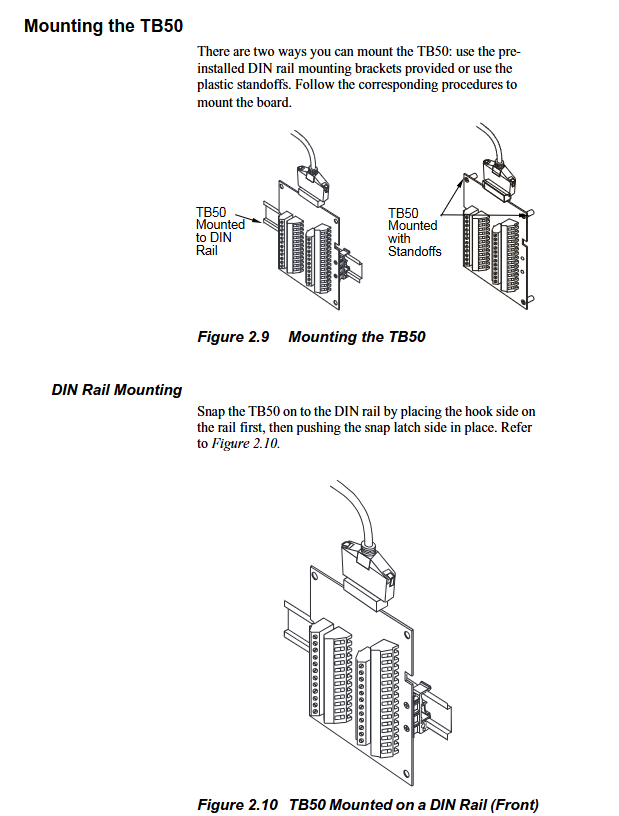

Terminal board (TB50) MLS300-TB50 50 50 pin SCSI interface terminal board, used for digital I/O, power and control output wiring, supports DIN rail or bracket installation

Expansion Module - DAC (Digital to Analog Converter): 2-channel configurable 4-20mA/0-5V/0-10V output

-SDAC (Serial Digital to Analog Converter): 1 high-precision analog output, supporting process variable retransmission to convert digital output to analog signal, suitable for analog control equipment such as valves and frequency converters

The MLS300-PS power module inputs 120/240V AC and outputs 15V DC/1.2A and 5V DC/4A, providing isolated power supply for the system

2. Hardware architecture logic

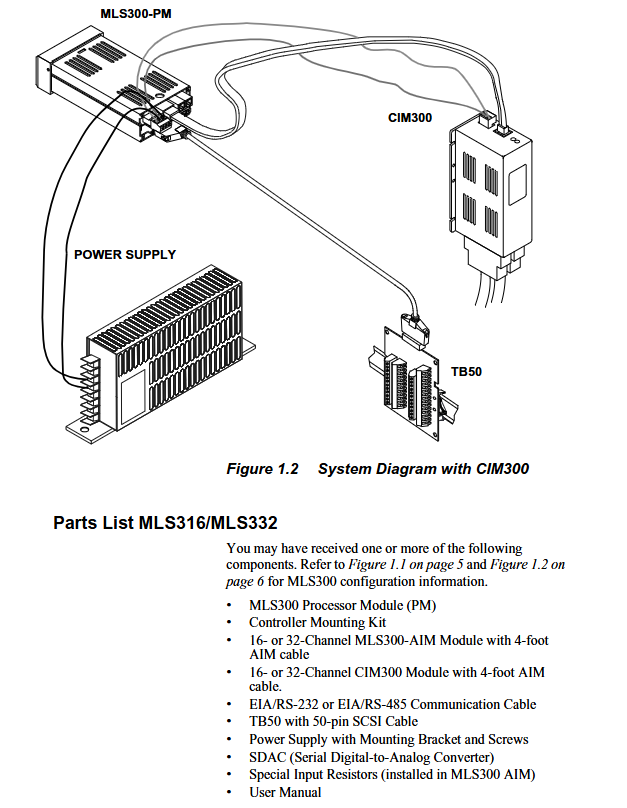

The system adopts a "master-slave" communication architecture, and the data flow is as follows:

Perception layer: Sensors (thermocouples/RTDs, etc.) transmit process signals to the AIM/CIM module, completing signal conditioning and A/D conversion;

Control layer: The processor module (PM) receives digital signals from AIM/CIM, generates control instructions through PID algorithm, and sends them to the TB50 terminal board;

Execution layer: TB50 transmits instructions to actuators such as solid-state relays (SSRs) and contactors to control heating/cooling equipment;

Monitoring layer: Implement parameter settings, status monitoring, and alarm processing through the front-end panel or upper computer (such as WatView software).

Key technical parameters

1. Input parameters

(1) Sensor support and accuracy

Input Type Range Accuracy (25 ℃ environment) Remarks

Thermocouple (Type J) -212~760 ℃ (-350~1400 ℉) ± 1.1 ℃ with cold end compensation, linearization, and open/short/reverse detection

Thermocouple (Type K) -268~1371 ℃ (-450~2500 ℉) ± 1.3 ℃-

RTD1 (high precision) -100~275 ℃ (-148~527 ℉) ± 0.35 ℃ (25 ℃) 0.1 ℃ resolution, only supported by MLS304/308

RTD2 (Wide Range) -120~840 ℃ (-184~1544 ℉) ± 0.9 ℃ (25 ℃) 1 ℃ resolution, only supported by MLS304/308

Linear current 0-20mA/4-20mA ± 0.03% full range requires external scaling resistor

Linear voltage 0-5V/0-10V/0-12V ± 0.03% full-scale-

Pulse input 0-2kHz resolution 0.006% used for encoder speed measurement (such as conveyor belt speed control)

(2) Input performance

Sampling rate: MLS316 is 1.5 times/second (60Hz), MLS332 is 0.75 times/second (60Hz);

Noise suppression: Common mode rejection ratio (CMR)>85dB at 60Hz, input filtering configurable (0-255 scan period);

Temperature coefficient: 40ppm/℃, ensuring measurement stability in a wide temperature environment.

2. Output and communication parameters

Parameter category specification value precautions

Digital output with 34 open collector outputs, each with a maximum sink current of 60mA (5V DC). The onboard power supply provides a total current of 350mA for controlling SSR, alarm indicator lights, etc. It can be configured as a control output or alarm output

Analog output without onboard analog output, needs to be expanded through DAC/SDAC module:

-DAC: 2-channel 4-20mA/0-5V/0-10V, accuracy ± 0.75%

-SDAC: 1 high-precision output with an accuracy of ± 0.05%. Full scale SDAC supports process variable retransmission and is suitable for scenarios that require high-precision analog signals (such as PLC analog inputs)

Serial communication interface: EIA/TIA-232 (single device, maximum 50m), EIA/TIA-485 (multi device, maximum 4000ft);

Baud rate: 2400/9600/19200bps;

Protocol: Modbus RTU, Anafaze protocol, Allen Bradley PLC/2 compatible protocol EIA/TIA-485 supports networking of 32 devices and requires 200 Ω terminal resistors to be configured at both ends of the bus

Power requirements: Processor module: 12-24V DC ± 15%, maximum 1A;

AIM/CIM module: 5V DC (provided by the processor module). It is recommended to use an isolated power supply to avoid sharing the circuit with high-power devices and reduce interference

Installation and wiring specifications

1. Pre installation requirements

Environmental conditions: working temperature 0-50 ℃, storage temperature -20-60 ℃, relative humidity 10% -95% (no condensation); Keep away from strong electromagnetic interference sources (such as frequency converters and high-voltage cables) and avoid vibration (amplitude ≤ 0.5mm, frequency ≤ 50Hz).

Qualification requirements: Installation personnel must have industrial electrical installation qualifications, and high-voltage wiring (such as power module input) must be operated by certified electricians; Prepare torque wrenches (0.5-0.6Nm), shielded cables, crimping tools, etc.

Space requirements: A 1.96 × 3.78-inch (50 × 96mm) opening should be reserved for the installation of the processor module panel, and a wiring space of ≥ 7.4 inches (188mm) should be reserved on the back; The AIM module requires a reserved installation space of 6.5 x 5 x 5.75 inches (165 x 127 x 146mm).

2. Installation steps of core components

(1) Processor module (MLS300-PM)

Cut 1.8 × 3.63 inch (46 × 92mm) openings on the panel, remove module brackets and baffles;

Insert the module into the opening, fit the installation ring on the back, fix the upper and lower brackets, and tighten the screws (torque 0.5Nm);

Connect the AIM/CIM communication cable (RJ45 interface, labeled "To AIM"), TB50 50 50 pin SCSI cable, and power supply (TB1 terminal:+V to 12-24V DC, COM to negative pole).

(2) Input module (AIM/CIM)

AIM module:

Fix the AIM-TB terminal board with 4 # 6 screws to ensure grounding (grounding resistance ≤ 4 Ω);

Connect sensor cables: thermocouple "+" is connected to A+, "-" is connected to A -; RTD 3-wire system requires the "common end" to be connected to A COM, and the "signal end" to be connected to A+/A -;

Connect AIM to the processor module via RJ45 cable and test AIM power supply (TB3 terminal:+5 IN to PWR COM voltage 4.75-5.25V DC).

CIM module:

Support DIN rail or direct installation, connect sensors through D-Sub 50 connectors (J1 for 16 channels, J2 for 32 channel expansion);

Communication cable (RJ45) connected to CIM J3 interface, power supply (TB2 terminal: EX connected to processor EX, COM connected to processor COM).

(3) Terminal board (TB50)

Choose DIN rail or bracket installation, connect 50 pin SCSI cable to the processor module;

Wiring specifications:

Digital output (terminals 9-42): When controlling SSR, connect+5V to the positive pole of SSR and connect the output terminal to the negative pole of SSR;

Digital input (terminals 43-50): One end of the external switch is connected to the input terminal, and the other end is connected to CTRL COM (terminal 3/4);

Power terminal (1-2):+5V is the output (for SSR, etc.), CTRL COM is the common terminal, and grounding is prohibited.

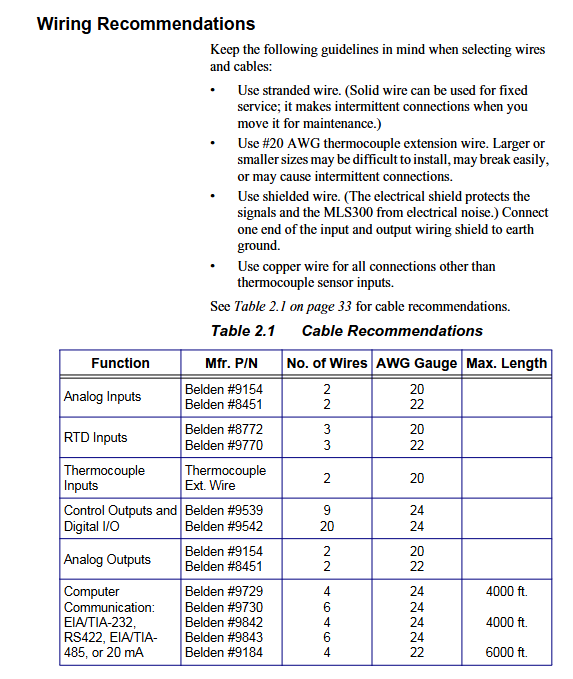

3. Wiring and anti-interference requirements

Recommended specifications for cable types and wiring requirements

Sensor cable thermocouple: 20AWG thermocouple extension wire; RTD: 22AWG shielded twisted pair cable; Linear signal: 22AWG shielded twisted pair cable should be kept away from high-voltage cables (≥ 10cm), and the shielding layer should be grounded at one end (processor end); RTD cable length ≤ 100m

Control the output cable with 24AWG multi-core shielded wire and separate it from the input cable to avoid parallel laying; SSR control line length ≤ 50m

Communication cable EIA/TIA-232: Belden 9729 (6-core shielded wire, ≤ 50m); EIA/TIA-485: Shielded 9843 (4-core shielded twisted pair, ≤ 1200m) with both ends of the shielding layer grounded; The EIA/TIA-485 bus requires a 200 Ω terminal resistor to be configured at both ends

Basic Operations and Configuration

1. Startup and initialization

After confirming that the wiring is correct, turn on the power and the processor module display screen will light up. After about 1 second, it will enter the "bar chart display" (default display shows 8 circuit statuses);

If an "AIM COMM FAIL" alarm occurs, it is necessary to check whether the AIM/CIM communication cable is securely plugged in and whether the power supply is normal;

The first startup requires the execution of the "NO key reset" (press and hold the NO key in the power-off state, press YES to confirm after powering on), and restore the factory default parameters (skip when backing up the configuration in advance).

2. Core operations (front-end panel)

(1) Loop monitoring and parameter adjustment

Display switching:

Press the BACK key to switch between "Bar Chart Display" (8 circuit status), "Single Circuit Display" (Single Circuit PV/SP/Output%), and "Job Display" (Current Running Job);

Under single circuit display, press the YES/NO key to switch circuits, press the CHNG SP key to modify the set point (press YES/NO to adjust the value, press ENTER to confirm).

Control mode switching:

Press the MAN/AUTO key to switch between "AUTO" and "MAN" modes; In manual mode, adjust the output percentage (0-100%) according to YES/NO;

Press MAN/AUTO+ENTER to start "TUNE", and the controller will automatically calculate PID parameters (ensuring process stability and no severe disturbances).

(2) Alarm processing

When the alarm is triggered, the display screen automatically switches to the fault circuit, displaying the alarm code (such as "FS" for sensor fault, "HP" for high process alarm), and the buzzer is activated;

Press the ALARM ACK button to confirm the alarm. If there are multiple alarms, they need to be confirmed one by one; After troubleshooting, the alarm will automatically clear;

The global alarm output (terminal 8) is activated when any unconfirmed alarm occurs, and can be connected to an external alarm light or buzzer.

3. Basic parameter configuration (Setup menu)

Enter the Setup menu through the "three key combination" (ENTER → ALARM ACK → CHNG SP), and the core configuration items are as follows:

Menu Name Key Parameter Configuration Description

When communicating with multiple devices, a unique address (1-247) must be set for the SETUP GLOBAL ParameterS controller address, communication baud rate, and power on output status; The baud rate needs to be consistent with the upper computer (default 19200bps)

SETUP LOOP INPUT input type, unit, filter coefficient selection corresponding to sensor type (such as "J T/C" and "RTD1"); Input filtering (0-255 scan) is used to suppress noise

SETUP LOOP Control PARAMS heating/cooling PID parameters (PB/TI/TD), the smaller the output filter PB (proportional band), the higher the gain; The longer the TI (integration time), the stronger the ability to eliminate steady-state errors; TD (Differential Time) is used to suppress overshoot

SETUP LOOP OUTPUTS heating/cooling output enable, output type, sensor fault output type optional "TP (time ratio)" "DZC (distributed zero crossing)" "SDAC"; When the sensor fails, the output can be set to 0% (default) or a custom value

SETUP LOOP ALARMS high/low process alarm, deviation alarm, alarm dead zone high process alarm set point needs to be higher than the process upper limit; Set the deviation alarm to SP ± 5% (to avoid frequent alarms); Set the dead zone to 2-5 (unit consistent with PV)

Advanced features (firmware optional)

1. Enhanced Features firmware

(1) Cascade Control

Application scenario: Suitable for processes with "primary secondary" variables (such as reactor temperature jacket temperature control), where the main circuit output serves as the secondary circuit set point;

Configuration steps:

Enter the SETUP LOOP CASCADE menu and select "PRIM. LOOP" (such as reactor temperature loop 1);

Set the "Base SP", "Minimum/Maximum Set Point", and "Heating/Cooling Span (HT/CL SPAN)" to define the magnitude of the impact of the main circuit output on the secondary circuit set point;

The secondary circuit (jacket temperature circuit 2) needs to enable the "cascade mode" to ensure that the sampling period of the main and secondary circuits matches.

(2) Ratio Control

Application scenario: Suitable for processes that require proportional control (such as KOH solution dilution, water flow KOH flow 1:2);

Configuration steps:

Enter the SETUP LOOP RATIO CON menu and select "MSTR LOOP" (water flow circuit 1);

Set "CTRL RATIO" (e.g. 0.5, KOH flow=water flow x 0.5), "SP DIFF" (compensating deviation, default 0);

The proportional circuit (KOH flow circuit 2) automatically follows the changes in the main circuit PV and maintains the set ratio.

2. Slope - Insulation Fasteners (Ramp/Soak)

Application scenario: staged temperature control process (such as material annealing: heating → insulation → cooling), supporting 17 profiles, each profile containing 20 segments;

Core functions:

Ramp: Rise from the current SP to the target SP within a set time (e.g. 10 ℃/min to 200 ℃);

Soak: Maintain the target SP setting time (such as holding at 200 ℃ for 60 minutes);

Trigger and Event: Each segment can be configured with 2 digital trigger inputs (such as external signal activation) and 4 event outputs (such as initiating agitation);

Configuration steps:

Enter the SETUP RAMP/SOAK PROFILE menu, select Profile (A-Q), and set the "Time Reference" (HH: MM/MM: SS);

Edit Segment: Set "Segment Time", "Target SP", "TOLERANCE" (if ± 2 ℃, pause timing if exceeded);

Assign Profile to the target circuit, press the RAM/SOAK key to start, and the display screen will show the remaining time and current segment number in real time.

Troubleshooting and Maintenance

1. Common fault handling

Possible causes and solutions for the fault phenomenon

The display screen is not properly connected to the power supply, and the processor module is faulty. Check the TB1 terminal voltage (12-24V DC); Replace the processor module for testing

Abnormal sensor readings (high/low), incorrect sensor wiring, incorrect input type configuration, interference confirmation of thermoelectric dipole/RTD wiring; Check the "Input Type" in the Setup menu; Check the grounding of cable shielding

No response output enabled, SSR fault, loose TB50 wiring entering SETUP LOOP OUTPUTS confirmation output enabled; Measure the voltage at the SSR control terminal (conducting at 5V DC); Re tighten the terminal screws

Communication failure address/baud rate mismatch, cable failure, EIA/TIA-485 terminal resistance not connected, check the communication parameters between the controller and the upper computer; Use a multimeter to test the continuity of communication cables; Connect a 200 Ω resistor at the beginning and end of the bus

Alarm for "FS (sensor malfunction)" thermocouple open/short circuit, RTD disconnection, input module malfunction check sensor cable continuity; Replace the sensor for testing; Replace the AIM/CIM module for testing

2. Regular maintenance

Requirements for maintenance cycle operation content

Check the display screen daily for any errors and ensure that the alarm light is functioning properly; Do not wipe the display screen with alcohol when cleaning the panel and sensor; The sensor probe is free of oil stains/damage

Check the wiring terminals weekly for any looseness; Test the emergency stop and alarm function terminals and tighten the screw torque to 0.5-0.6Nm; confirm the ALARM ACK is valid after triggering the alarm

Monthly calibration of critical circuits (using standard signal sources to simulate sensor inputs); The calibration error of the cooling holes in the cleaning AIM/CIM module should be ≤ 0.1% of the full range; Compressed air blows away dust from the heat dissipation holes (pressure ≤ 0.3MPa)

Replace the processor module battery (CR2032, after power failure to avoid configuration loss) annually; Check that the battery replacement time for the shielding layer of the communication cable is ≤ 5 minutes; The shielding layer is undamaged and well grounded

Order

Ordering code rules (core position)

Code bit meaning optional values

Input module 16=AIM316 (16 channels), 32=AIM332 (32 channels) C1=CIM316、C2=CIM332 -

Firmware Type 1=Standard, 2=Extruder Specific, 3=Enhanced Features, 4=Ramp/Soak, C=Custom-

Terminal board 0=none, 1=18 pin terminal block, 2=50 pin terminal block (including 3-foot SCSI cable)-

Communication jumper 0=EIA/TIA-232, 1=EIA/TIA-485, 2=EIA/TIA-485 terminal matching-

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923