K-WANG

Emerson MMS 3120 Dual Channel Bearing Vibration Transmitter

Emerson MMS 3120 Dual Channel Bearing Vibration Transmitter

Equipment Overview

The MMS 3120/xxx-xxx dual channel bearing vibration transmitter is part of the improved MMS 3000 transmitter system, used for monitoring and protecting various types of turbomachinery. This transmitter has highly flexible hardware options and multiple combination possibilities, which can best adapt to the needs of the corresponding factory. It achieves economic measurement and monitoring of absolute bearing vibration through the use of seismic absolute vibration sensors, and complies with VDI 2056/.. And API 670 standards.

Application scenarios

Suitable for various types of turbomachinery, fans, compressors, gearboxes, pumps, and similar rotating machinery. Due to its bus capability, it is suitable for both large systems equipped with programmable logic controllers and hosts (such as power plants, refineries, and chemical plants) and small factories with few measurement points and scattered data processing. Can be used in conjunction with all EPR absolute bearing vibration sensors, such as PR 9268/20, PR 9268/30, PR 9268/60, and PR 9268/70.

Function and Design

Signal conversion: Convert the signal of a vibration sensor into two independent signals proportional to the vibration velocity or amplitude (peak to peak), or output signals proportional to the maximum value of these characteristic values.

Monitoring function: Integrated module and sensor monitoring function, capable of detecting faults in sensors and module electronic devices. In the event of an error, the status of the "OK" output will change, and the 4-20 mA current output will indicate 0 mA.

Configuration method: All necessary configurations are completed through MMS 3910W configuration software. The transmitter comes with standard configurations suitable for most applications at the factory, or other configurations can be made at the factory according to requirements.

Technical parameters

Sensor Input

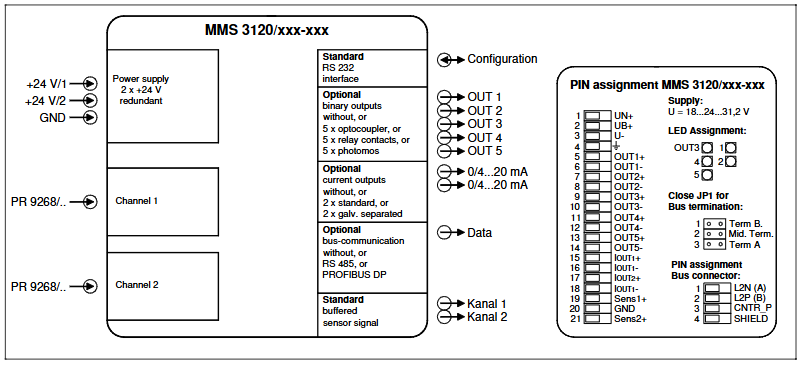

Two independent inputs for PR 9268/20, PR 9268/30, PR 9268/60, and PR 9268/70 seismic vibration sensors.

Sensor connection: Harting connector.

Measurement range: It can be freely selected through configuration software based on the measurement range of the applied sensor.

Frequency range (-3dB): High pass filter 5/10/15 Hz; low-pass filter 50... 1500 Hz.

output

Current output: The standard is two current outputs, proportional to the selected characteristics and related to system grounding, which can be freely allocated to the measurement channel; Choose between two electrically isolated current outputs or no current output. The output range is 0/4... 20 mA or 20... 4/0 mA, with a maximum load of 500 ohms and open and short circuit protection.

Buffer sensor signal: Two signal outputs for analysis and diagnosis, one for each channel, proportional to the dynamic sensor signal, accessed through terminals, unfiltered voltage output of ± 5.0 V, with an error of ± 2.5%.

Function output: A total of 5 function outputs are provided, which can be freely allocated through configuration software to indicate limit values or clear channel status, etc. There are multiple options, such as no function output, 5 optocoupler outputs, 5 relay contacts (normally open contacts), 5 photoelectric MOS relays, etc.

Data interface: The standard is RS 232 interface, used for transmitter configuration and measurement data display; Optional RS485 bus (with epro protocol V2.0) and PROFIBUS DP.

Accuracy and stability

Linear error (without sensor): 0.2% at 25 ° C.

Linear error (with sensor):<2.2% at 25 ° C.

Output temperature stability:<0.08%/10K.

Long term drift: up to 1% of full scale.

Power supply: Optional redundant power supply, with diode decoupled LED, nominal voltage+24 V DC, voltage range+18...+31.2 V DC, power consumption depends on built-in options, maximum 6 W.

Shell and Protection

Shell: Aluminum, non corrosive.

Protection level: IP 65 (compliant with DIN 40050, IEC 144), CE certification, EMC testing in accordance with EN 55011 and EN 61326.

Environmental conditions (compliant with IEC 359, DIN 43745)

The maximum allowable temperature for installation surface is 65 ° C (90 ° C when installed on bolts with a spacing of 10mm).

Working temperature range: -20...+65 ° C (-20...+45 ° C when installed on 10 mm spaced bolts).

Allowable relative humidity: 0... 95%, no condensation.

Vibration and impact: impact 20 g/2 ms; Vibration at 5 g/60 Hz.

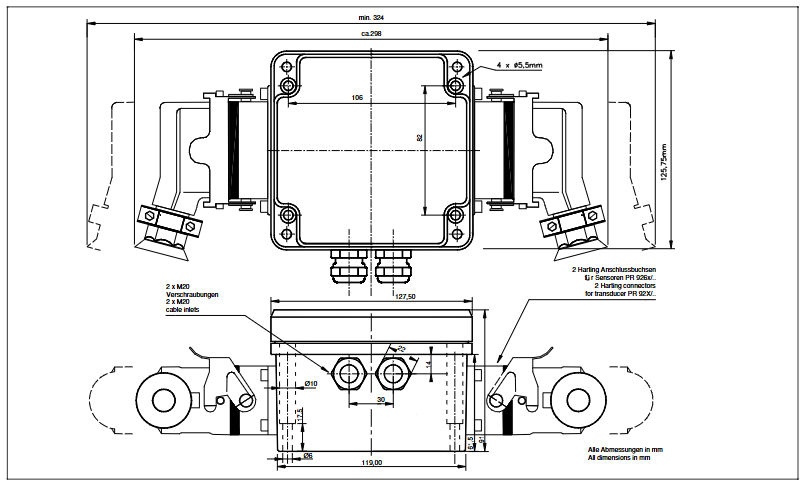

Installation and Dimensions: The preferred installation direction is downwards with the cable gland. Please refer to the drawing for the dimensions. The maximum net weight is 1.3 kg and the maximum gross weight is 1.5 kg.

Module and sensor monitoring

Internal module monitoring continuously checks the following functions: whether the input signal is within the predefined range; Is the cable between the transmitter and sensor normal (no short circuit/broken wire); System voltage. The monitoring status of modules and sensors can be signaled through the switch contacts of functional outputs.

Configure parameters and operating modes

Main configuration parameters: configured through MMS 3910W configuration software, adjustable parameters include KKS identification for each channel, operating mode, sensor sensitivity, series resistance of safety barriers, measurement range, etc. (may vary depending on the selected operating mode and measurement function).

Operation mode: Provides multiple measurement modes, which can be configured through MMS 3910W configuration software. In single channel and dual channel modes, the selectable measurement modes include vibration amplitude (SO-P, SP-P, MAX (x, y)) and vibration velocity (VRMS, MAX (x, y)).

Ordering options and standard models

Ordering Options

Communication: RS 232, RS 485, PROFIBUS DP.

Sensor inputs K1 and K2: two identical input channels that cannot be mixed, corresponding to PR 9268/.

Output characteristics: None; 2 with system reference (standard); Two electrical isolations.

Function output: None; 5 optocouplers (standard); 5 relay contacts (normally open contacts); 5 photoelectric MOS.

Display: None (standard); Equipped with an 8-bit display.

Standard Model

MMS 3120/010-000: Sensor PR 9268/.., RS 232, no bus communication, current output with common ground, no functional output, no display, order number 9100-03025.

MMS 3120/011-000: Sensor PR 9268/.., RS 232, no bus communication, current output with common ground, functional output, no display, order number 9100-03026.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923