K-WANG

MOOG MSD Multi Axis Servo Drive System (DC-AC)

MOOG MSD Multi Axis Servo Drive System (DC-AC)

Product Overview

Moog MSD Multi Axis Servo Drive System (DC-AC) is a modular solution for medium to high power multi axis control scenarios. Its core advantages lie in flexible scalability, high safety, and multi scenario adaptability. By combining seven sizes of drive modules with two power supply modes, it can quickly build complex systems from single axis to multi axis collaboration, suitable for various applications such as industrial automation, precision motion control, and heavy equipment drive. It complies with international standards such as IEC/EN 61800-5-1, CE, UL, and has a complete EMC electromagnetic compatibility design.

Detailed explanation of core hardware specifications

(1) Size and current specifications (summary of key parameters)

table

Size Model Example Rated Current (A rms) Peak Current (A rms) Cooling Method Switching Frequency (kHz)

Size 1 G393-004 4 4 8 air-cooled 4/8/12/16

Size 2 G393-008 9.3 15.9 air-cooled 4/8/12/16

Size 3 G393-016 16 16 33.6 air-cooled/liquid cooled 4/8/12/16

Size 4 G393-024 24 48 air-cooled/liquid cooled 4/8/12/16

Size 5 G393-045 45 45 90 air-cooled/liquid cooled 4/8/12/16

Size 6A G393-090 90 90 180 air-cooled/liquid cooled 4/8/12/16

Size 7 G397-250 250 425 liquid cooling 2/4

(2) Key electrical parameters

Input voltage: Supports 565V DC (AC-AC servo drive power supply), 650/678/770V DC (Power Supply Unit power supply)

DC link capacitor: Size 1 (60 μ F) - Size 7 (7200 μ F), supports multi module capacitor coupling

Output characteristics: 3-phase AC output, rotating magnetic field frequency 0-400Hz, motor cable length ≤ 10m (standard)

Control power supply: 24V DC ± 10%, maximum starting current 10A, rated current 2-8A (depending on size)

(3) Cooling system parameters

table

Cooling type, suitable size, working temperature range, special requirements

Air cooled size 1-6A -10 ℃ to+40 ℃ (+40 ℃ to+55 ℃ with a capacity reduction of 2% -4%/℃), heat sink temperature ≤ 65 ℃

Liquid cooling size 3-7-10 ℃ to+40 ℃ (+40 ℃ to+55 ℃ with a capacity reduction of 2%/℃) Cooling liquid temperature 5-40 ℃, pressure 1-2 bar, flow rate 3-14L/min

Core functions and software tools

(1) Core functional characteristics

Safety function: Integrated STO (Safe Torque Off) safety torque shut-off function, compliant with SIL CL3, PL "e" safety level, supports dual channel monitoring and diagnostic output

Feedback adaptation: compatible with rotary transformers (with phase/amplitude correction), SinCos encoders (5-8V power supply) EnDat 2.2、SSI、Hiperface ® Waiting for various high-precision feedback devices

Communication capability: Supports mainstream fieldbus protocols such as EtherCAT, PROFINET IRT, SERCOS II/III, CANopen, PROFIBUS-DPV1, VARAN, etc

Protection mechanism: multiple protections such as overcurrent, overtemperature, undervoltage, overvoltage, motor temperature monitoring (PTC/NTC/KTY), cable breakage detection, etc

Energy optimization: DC link sharing design, supporting inter axle energy recovery, reducing braking resistance losses

(2) Software and Configuration Tools

Moog DriveAdministrator 5: Windows system compatible, supports parameter configuration, online diagnosis, real-time monitoring, fault history query (last 20 faults), batch parameter replication

Local operation: Front end 2 operation keys (T1/T2)+2-digit 7-segment digital display, supporting IP address setting, bus address configuration, and parameter reset to factory settings

Diagnostic function: Error code display ("Er"+error number+fault location), real-time status indication (power/ready/running/fault)

Power supply mode and networking scheme

(1) Comparison of two power supply modes

table

Advantages and disadvantages of core components in power supply mode, applicable scenarios

Power Supply Unit (G396 series) provides energy feedback to the grid with low power consumption; Support reactive power compensation; The initial investment for stable DC voltage is high; Large space occupation, long-term operation, high regenerative energy scenario

High power AC-AC servo drive module with low cost; Small installation space; Simple wiring for regenerative energy dissipation through braking resistors; Oversized design is required for short-term operation and low regenerative energy scenarios

(2) Key requirements for networking

DC link coupling: Size 1-5 supports pre installed cables (20-193mm, 20mm ² copper bars), Size 6A-7 requires custom cables (35-95mm ²)

Maximum module quantity: A single Power Supply Unit can connect up to 6 DC-AC drive modules

Synchronization performance: Multi axis synchronization is achieved through EtherCAT bus, with synchronization error ≤ 1 μ s

Installation and environmental requirements

(1) Mechanical installation

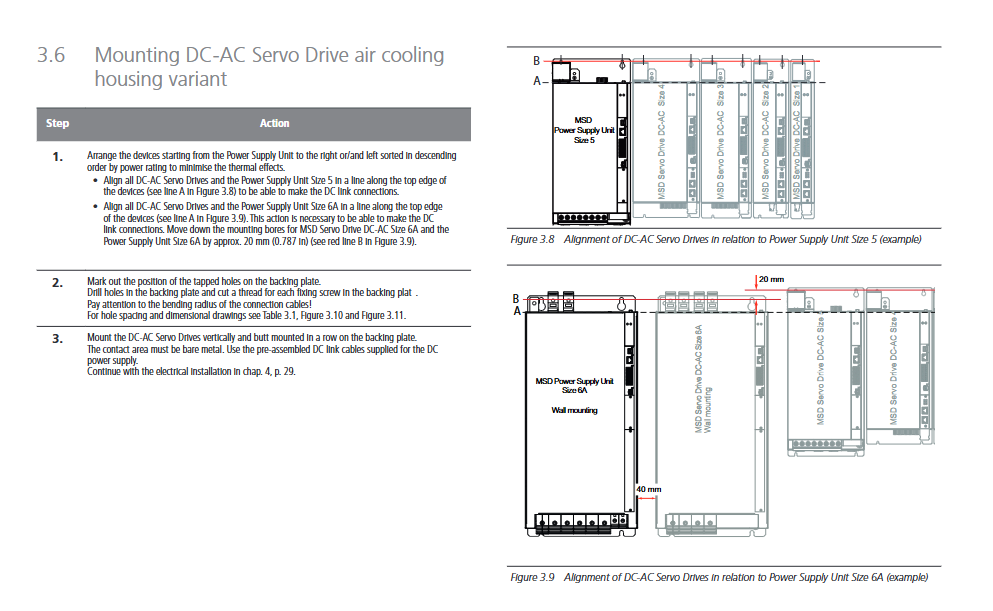

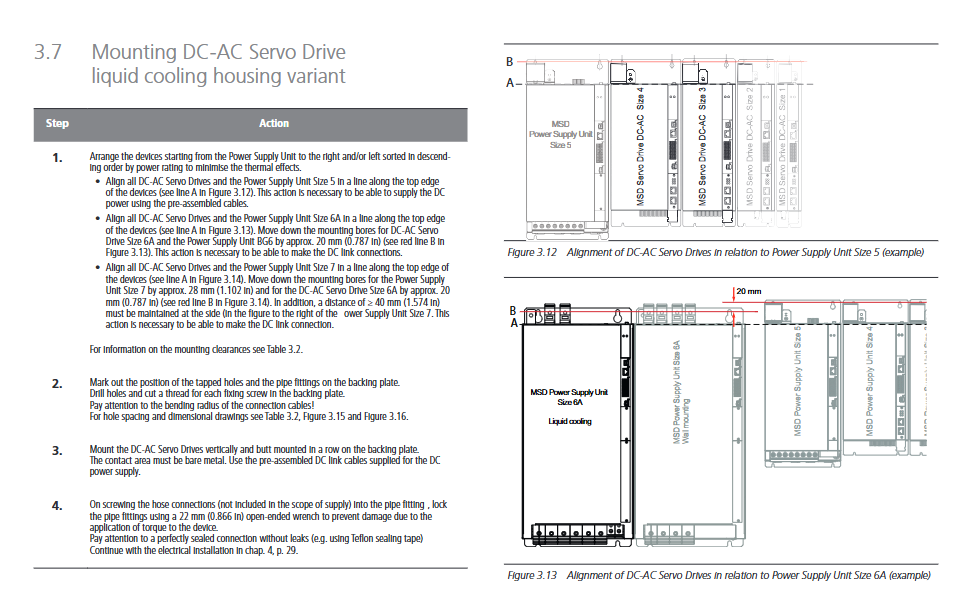

Installation method: 35mm standard DIN rail vertical installation, backboard needs to be grounded (chrome/galvanized material is preferred)

Installation gap: The side spacing of the air-cooled module is ≥ 2mm, and the spacing of the Size 6A air-cooled module is ≥ 40mm; the liquid cooled module needs to reserve space for the coolant interface

Requirements for switchgear: protection level IP4X (conventional), IP54 (with STO function enabled), pollution level 2 (IEC/EN 60664-1)

(2) Electrical installation

Grounding specifications: star shaped grounding topology, PE conductor cross-section ≥ 10mm ² copper, large-area grounding at both ends of the shielding layer

Cable requirements: Motor/encoder cables need to be twisted pair shielded, and the distance between analog signal and power cables should be ≥ 200mm

Attention to wiring: The control power supply (24V DC) should be connected before the main power supply. After power failure, wait for the capacitor to discharge (≥ 30 minutes)

(3) Environmental restrictions

Working temperature: -10 ℃ to+40 ℃ (rated),+40 ℃ to+55 ℃, requiring capacity reduction (air-cooled 2% -4%/℃, liquid cooled 2%/℃)

Altitude: ≤ 1000m (rated), with a capacity reduction of 1% for every 100m increase between 1000-2000m

Vibration shock: Working vibration 9-200Hz (1g), shock 10g (11ms)

Accessories and Compliance Certification

Special accessories: pre installed DC link cable, motor/encoder special cable (length 1-50m), braking resistor (15 Ω -4.7k Ω), EMC filter (AT6048/AT6049 series)

Compliance certification: CE (Low Voltage Directive 2014/35/CE, EMC Directive 2014/30/CE), UL, EAC, IEC/EN 61800-5-1

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923