K-WANG

MOOG DM2020 Multi axis Servo Drive

MOOG DM2020 Multi axis Servo Drive

Product Overview

Moog DM2020 is a modular servo drive designed for high-precision multi axis motion control scenarios. Its core advantages lie in compact design, flexible expansion, and high synchronization. By combining axis modules with power modules, complex systems with 12 or more axes can be built, saving 50% of installation space compared to traditional independent drivers. The shared DC BUS between axes enables energy recovery, reducing energy consumption and braking resistance losses. It integrates high safety STO functions and intuitive configuration tools, and is suitable for various high-end applications ranging from industrial automation to energy conversion.

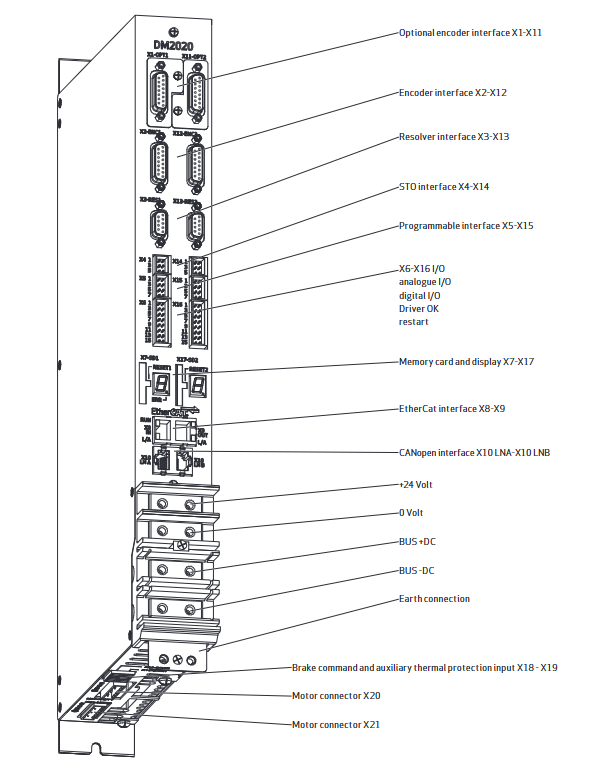

Detailed explanation of core hardware components

(1) Axis module (core execution unit)

Specification Category Key Parameter Details Explanation

Mechanical size width options are 50mm (1.97in), 75mm (2.95in), 100mm (3.94in), 200mm (7.87in); Height 455mm, depth 249mm (uniform specifications)

Select single axis or dual axis for configuration mode, with dual axis supporting primary/secondary or independent operation

Current specification rated/peak rated: 2-128Arms (8kHz carrier frequency); Peak value: 4-256Arms (different widths correspond to different ranges)

Feedback interface standard configuration rotary transformer interface (supports pole number software configuration, attenuation/phase correction); Programmable Encoder Interface (EnDat 2.2/Hiperface/SinCs)

Optional configuration of a second encoder interface for the extended interface (consistent with the characteristics of the main interface); Motor brake control interface (24V 2A/shaft); Custom interface card slot (X1)

Cooling method: 50mm module for heat dissipation design: natural cooling; 75/100/200mm module: built-in ventilation fan

Weight range: Single machine weight 4.4kg (50mm single axis) -17.5kg (200mm double axis)

(2) Power module (energy supply unit)

Specification Category Key Parameter Details Explanation

Mechanical size width options are 50mm (1.97in) and 150mm (5.90in); Height 455mm, depth 249mm (consistent with shaft module)

Input parameters voltage/frequency 3-phase AC 65-528V; 50/60Hz; auxiliary power supply 24VDC ± 10% (1A)

Output specification rated/peak 50mm model: 54Arms rated/130Arms peak; 150mm model: 128Arms rated/256Arms peak

Protection function safety monitoring heat sink thermal protection (triggered at+71 ℃); Input phase loss detection; Overvoltage/undervoltage detection

Communication interface data exchange CANopen interface (used for module communication, parameter configuration, status monitoring)

Energy storage capacity capacitor configuration 50mm model: 1800 μ F; 150mm model: 4500 μ F

Cooling method and heat dissipation design. Both models are equipped with built-in ventilation fans

Weight data: Single machine weight 5.1kg (50mm), 13.5kg (150mm)

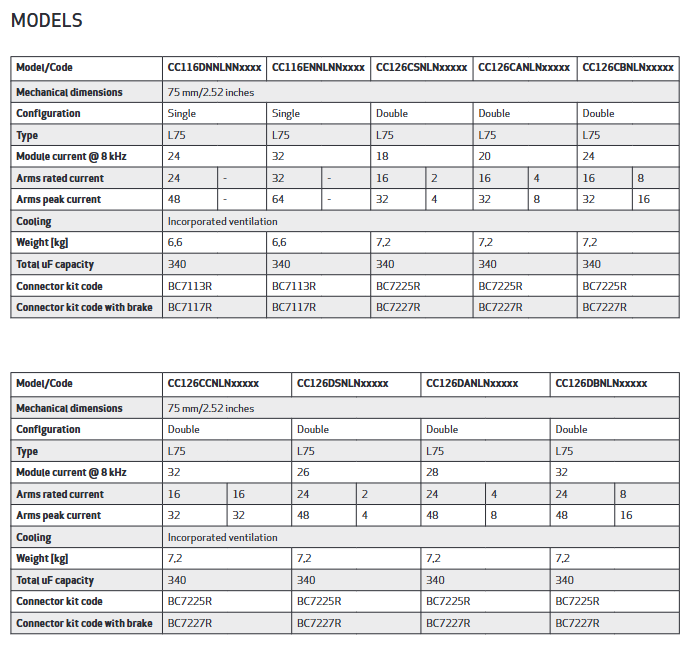

(3) Typical Axis Module Model Parameter Table

Module width model example configuration Rated current (Arms) Peak current (Arms) Cooling method Weight (kg)

50mm CC111SNNNNxxx single axis 2 4 natural cooling 4.4

50mm CC122BANLNxxxxx dual axis 4+2 8+4 built-in ventilation 5.8

75mm CC116ENNLNNxxxx single axis 32 64 built-in ventilation 6.6

75mm CC126CBNLNxxxx dual axis 16+8 32+16 with built-in ventilation 7.2

100mm CC118GNNLNNxxxx single axis 64 128 built-in ventilation 8.0

100mm CC128EDNLNxxxx dual axis 32+24 64+48 built-in ventilation 8.6

200mm CC130JNNLNNxxxx single axis 128 256 built-in ventilation 17.5

200mm CC140GFNLNxxxxx dual axis 48+48 96+96 built-in ventilation 17.5

Core functions and software tools

(1) Core functional characteristics

Multi axis collaboration: The dual axis module supports master-slave mode, and multiple modules are interconnected through CANopen to achieve high-precision axis synchronization (suitable for scenarios such as gantry frames and energy conversion lines);

Energy optimization: Shared DC BUS design, mutual energy supplementation between axles, reducing energy consumption of braking resistors and total system power consumption;

Safety guarantee: All shafts are integrated with STO safety torque shutdown function, in compliance with SIL CL3 and PL "e" safety levels, and support independent shaft management;

Signal isolation: The internal signal area and power area are physically separated to enhance EMC electromagnetic compatibility and reduce wiring interference;

Flexible wiring: The motor power connector is fixed with screws, without the need for specialized crimping tools; The 24V auxiliary power supply shares a busbar with the DC BUS (maximum load capacity of 250A).

(2) Software and Configuration Tools

Operating environment: GUI configuration tool based on Windows system;

Communication interface: Supports RS232 or CANopen connection with PC;

Core functions:

System configuration (axis parameters, motor parameters, feedback type);

Real time monitoring (variable status, fault diagnosis, axis calibration);

Data recording: 16KHz high-frequency sampling, supporting MMC memory card storage;

4-channel oscilloscope: Real time viewing of analog data inside the driver (such as feedback amplitude and output current), assisting in startup debugging and troubleshooting;

Configuration backup: System parameters can be saved as files and support fast loading.

Expansion options and accessories

Category specific options Key parameter usage

The motor braking option is equipped with a built-in brake control module 24VDC, 2A/axis control motor braking device, and dual axis module with independent interfaces for each axis

Feedback extension: The second encoder interface is compatible with EnDat 2.2/Hiperface/SinCos to achieve machine side secondary feedback and improve control accuracy

Braking resistor standard/insulation type 50mm power supply: 15 Ω 370W (standard), 16 Ω 500W (optional); 150mm power supply: 4.7 Ω 1000W (recommended) consumes excess braking energy to protect the driver

Connector kit for shaft module/power module, including signal, power, and brake resistor connector module wiring and maintenance backup

Storage Expansion MMC Memory Card Supports Data Recording and Configuration Storage Offline Reading of Sampling Data, Backup System Configuration

Auxiliary capacitor module (ABC) ABC1-ABC5 with a capacity of 1800-5400 μ F increases braking energy storage and reduces braking resistance losses (200 cycles per minute can save 3kW)

Multiple models of EMC filters available with rated voltage of 480-600VAC, 50/60Hz to enhance system electromagnetic compatibility and adapt to industrial environments

Environmental and Compliance Characteristics

Detailed explanation of key parameters for categories

Temperature range for operation/storage/transportation: 0-40 ℃ (with a capacity reduction of 2% per ℃ at 55 ℃); Storage: -25-55 ℃; Transportation: -25-70 ℃

Humidity requirement: relative humidity of 15% -85%, no condensation

Altitude limit: Installation height up to 2000m (beyond which capacity reduction is required)

Mechanical resistance vibration/impact vibration: 2-9Hz (3mm), 9-200Hz (1g); Impact: 10g (11ms)

Protection level: Shell protection IP20

Compliance certification standards CE, UL, EAC; Compliant with the Low Voltage Directive (2014/35/CE) and the EMC Directive (2014/30/CE)

Adapt motors and feedback devices

(1) Motor type

Brushless synchronous motor

Asynchronous induction motor

(2) Feedback device type

Feedback type supports key features of specifications

Rotary transformer supports attenuation correction, cable phase correction, and amplitude gain adjustment for any number of poles

Incremental encoder SinCos signal 5-8V power supply, compatible with differential/single ended signals

Absolute encoder EnDat 2.2 single/multi turn, supports all digital signals

Absolute encoder Hiperface single/multi turn, supports SinCos signal

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923