K-WANG

MOOG T161 Series Rack Mount Digital Brushless Motor Controller

MOOG T161 Series Rack Mount Digital Brushless Motor Controller

The Moog T161 series is a 6U standard 19 inch rack mounted digital brushless motor controller based on microprocessors, supporting 1-6 axis PCB backplane configurations. Its core features include sine wave three-phase drive, programmable speed/current control, and rotary transformer feedback system. It is equipped with RS232/RS485 serial port and can be easily set up and debugged through handheld terminals and WinDrive/MOOGTERM software; We offer 4 models (T161-901 to -904) with continuous output current of 3.0-12.0A rms and peak output of 5.0-40.0A rms. They support single-phase/three-phase 220VAC direct power supply and have multiple protection functions such as overcurrent, short circuit, and overtemperature. The optional expansion function card (including encoder simulator) is suitable for industrial scenarios that require precise motor control. The working temperature range is 0 ° -55 ℃, and the minimum requirement for heat dissipation airflow is 300 C.F.M.

Product core positioning and overall architecture

Product positioning: T161 series is an industrial grade digital brushless motor controller launched by Moog. It adopts a microprocessor core design and complies with the 6U standard 19 inch rack installation specification. It focuses on multi axis collaborative control and convenient debugging, and is suitable for industrial automation scenarios with precise control requirements for motor speed and current.

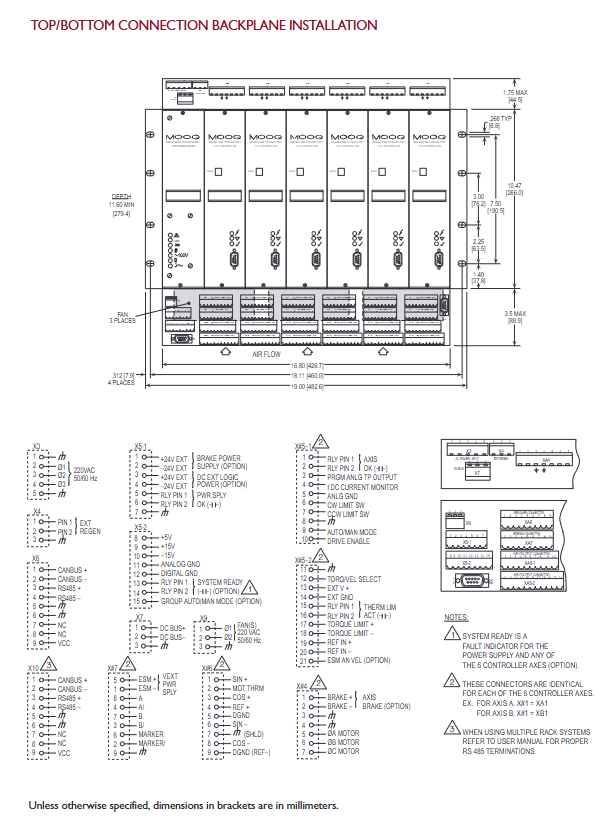

Overall architecture: Supports 1/2/3/4/6 axis PCB backplane configuration, with unified connector specifications for each axis (such as XA1 for axis A and XB1 for axis B), making it easy to expand multi axis systems; Built in heat sink, needs to be matched with fan tray to meet heat dissipation requirements and ensure continuous operation stability.

Core functions and configurations

(1) Core functions

Control mode: Supports programmable speed control and programmable current control, adapted to different load requirements; Built in function generator for easy debugging and optimization.

Feedback and detection: Using a rotary transformer based system to ensure control accuracy; Equipped with programmable simulation test points, supporting real-time status monitoring.

Debugging and Communication: Provides multiple debugging methods - handheld terminal (quick setup and tuning), PC WinDrive graphical software, MOOGTERM software; The communication interface includes RS232 and RS485 serial ports, supporting RS485 terminal configuration for multi rack systems (please refer to the user manual).

Scalability: Optional expansion function card, integrated with programmable encoder simulator to enhance system adaptability; The configuration is stored in non-volatile E2PROM, and the parameters are not lost after power failure.

(2) Key parameter configuration

table

Category details

Power supply specifications input voltage: single-phase/three-phase 220VAC; Frequency: 50/60Hz

Switching frequency T161-901/-902:10KHz; T161-903/-904:5KHz

Working environment temperature: 0 ° -55 ℃; Must meet the requirements for heat dissipation airflow (minimum 300 C.F.M., i.e. 8.49 cubic meters per minute, 2.0 inches of water column pressure)

Physical parameter dimensions: uniform height of 10.35in (262.9mm), width of 2.40in for T161-901 and 3.60in for T161-904, and uniform depth of 9.75in (247.7mm); Weight: 2.3kg for T161-901/-902/-903, 3.5kg for T161-904

Model classification and output specifications

table

Model Continuous output current (A rms) Peak output current (A rms) Switching frequency Weight

T161-901 3.0 5.0 10KHz 2.3kg

T161-902 5.0 10.0 10KHz 2.3kg

T161-903 8.0 20.0 5KHz 2.3kg

T161-904 12.0 40.0 5KHz 3.5kg

Protection function and connection method

(1) Comprehensive protection function

Core protection: watchdog timer (to prevent program failures), power failure monitoring, overcurrent protection, short circuit protection, motor temperature protection, controller over temperature protection, feedback loss protection, commutation fault protection, logic voltage protection, comprehensively ensuring equipment and motor safety.

(2) Connection method

Backboard type: Supports two installation methods: top/bottom connected backboards and rear connected backboards, suitable for different cabinet layouts;

Key interfaces: including motor wiring terminals (Ø A/Ø B/Ø C), limit switch interfaces (CW LIM SW/CCW LIM SW), brake power interface (BRAKE+/BRAKE -), CANBUS interface, RS485 interface, analog/digital grounding interface, etc;

Multi axis identification: Unified naming rules for each axis interface (such as X # 1 corresponding to the first interface of each axis), simplifying wiring and maintenance.

Additional features

Status indication: The SYSTEM READY signal (optional) serves as a fault indicator for the power supply and all axes, while the AXIS OK signal provides feedback on the single axis operating status;

Optional configuration: Supports functions such as GROUP AUTO/MAN MODE, TORQ/VEL SELECT, DRIVE ENABLE, etc., suitable for complex control scenarios;

Universality: Supports customized configuration, can contact the factory for personalized solutions.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923