K-WANG

MOOG Servo Electronics Products

MOOG Servo Electronics Products

Product Overview

Moog servo electronic equipment is a modular product system designed for the needs of electro-hydraulic servo control. Its core advantages lie in modular combination, multi voltage compatibility, and wide temperature adaptability. It can be customized to build open-loop/closed-loop control systems through Eurocard, Snap Trac, DIN Rail modules and supporting sensors and testers, covering the full scenario requirements from single axis simple control to multi axis complex collaboration. It is widely used in industrial automation, hydraulic systems, valve control and other fields.

Detailed Explanation of Core Product System

(1) Product classification and common parameters

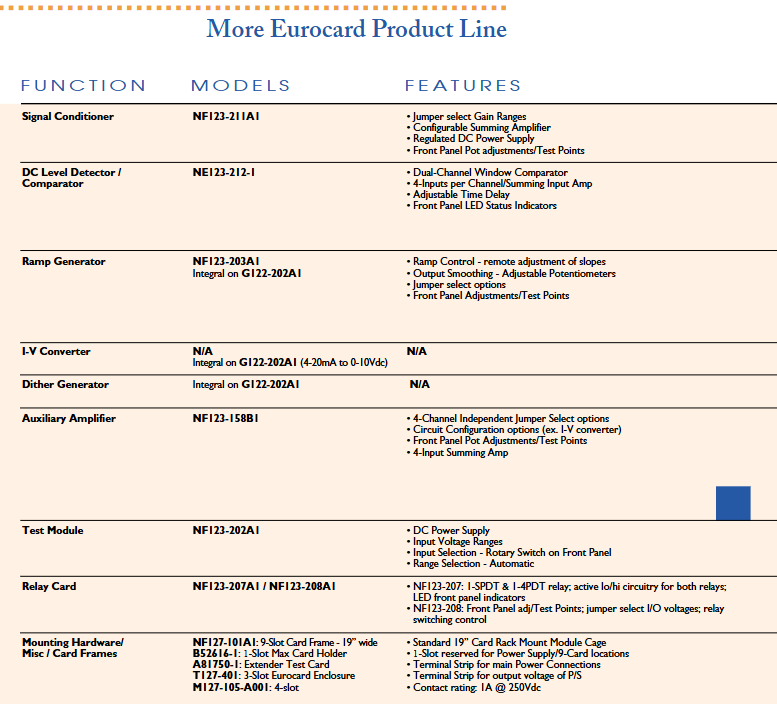

table

Product Type, Installation Method, Core Features, Power Supply Specifications, Adaptation Scenarios

Eurocard 19 inch standard rack (6U) 9-slot design (1 power slot+8 function card slots), supports multi-channel/complex systems 115VAC/230VAC or external DC 3-axis or more complex control, multi module collaboration

Snap Trac PVC track (Curtiss TR-3 type) is low-cost, easy to install and maintain, modular splicing 115VAC/230VAC 1-2 channel simple control, low-cost project

DIN Rail 35mm standard rail CE certification, compact space, quick insertion and removal of 24VDC space limited control cabinets, small servo systems

Auxiliary product independent installation/portable sensors (position/pressure/rotation), valve tester (5 models) sensors: DC power supply; Tester: Battery/valve power signal acquisition, valve debugging and maintenance

(2) Core functional modules (classified by function)

table

Function type represents model (Eurocard) represents model (Snap Trac) represents model (DIN Rail) Core parameters/characteristics

Servo amplifier G122-202A1 N122-142A G122-824 output current: Eurocard 10-100mA; Snap Trac 100mA max; Support PID and jitter selection

Servo controller N122-001 N121-132A - supports outer loop PID, inner loop gain adjustment, and current limitation

Power supply E128-210 integrated into N121-132A - Eurocard: ± 15Vdc@1.0A ;± 24Vdc@1.5A ;+ 5Vdc@3.0A optional

Oscillatory demodulator NF123-204A1 N123-134 G123-817 oscillation frequency: 100-2500Hz (Eurocard); 400Hz/2KHz/6KHz(Snap Trac)

Signal conditioner NF123-211A1 N123-135 G123-816 dual channel, supporting strain gauge/pressure sensor signal amplification

I-V converter integrated in G122-202A1 N123-139- Input: 4-20mA; Output: 0-10V/± 10V/± 5V

Slope Generator NF123-203A1 N123-137- Supports independent acceleration/deceleration control and smooth output adjustment

(3) Auxiliary products and tools

Sensors: Position sensor (magnetostrictive type: up to 6 feet; DCDT/LVDT: ± 0.2-3 inches), pressure sensor (single port/differential), tachometer (speed feedback), rotary potentiometer (340 ° range)/rotary transformer (position feedback);

Valve tester: 5 models (M040-104/G040-119, etc.), supporting battery powered/online testing, compatible with Moog servo valves/proportional valves, with LED indication and signal monitoring functions, CE certification.

Core control mode and configuration scheme

(1) Five major control modes

table

Key configuration steps for applicable scenarios of control mode core components

Open loop position control servo amplifier, actuator, command potentiometer simple positioning, manual monitoring feedback zero bias → set gain → hydraulic testing

Closed loop position control (2-stage valve) servo amplifier, position sensor, actuator precise positioning, no need for manual intervention zeroing → gain setting → stability testing

Closed loop position control (3-level valve) servo amplifier+oscillation demodulator, LVDT sensor precise positioning for high flow requirements, independent adjustment of inner/outer loop gain → zero bias calibration

Force control servo amplifier, signal conditioner, pressure sensor/load cell constant force output scene pressure signal calibration → force voltage conversion → gain adjustment

Speed control (with acceleration limit) servo amplifier, tachometer, I-V converter constant speed control (such as conveyor, mixer) integral control setting → speed range calibration → stability testing

(2) Typical Configuration Example

Dual axis PLC servo system (Snap Trac): N123-139 (I-V conversion)+N123-137 (ramp generation)+N121-132A (servo controller)+position sensor+DC level detector, realizing PLC instructions to dual axis cooperative control;

Complex multi axis system (Eurocard): E128-210 (power supply)+G122-202A1 (servo amplifier x multiple blocks)+NF123-204A1 (oscillation demodulator)+NE123-212-1 (DC level detection), supporting cooperation of more than 3 axes.

Key Performance and Installation Requirements

Environment and Protection: Operating Temperature -20 ° C to 50 ° C; Outdoor Installation Requires NEMA 4 Sealed Cabinet; The Eurocard/Snap Trac needs to be installed in an electrical cabinet with sufficient cooling;

Electrical specifications: AC power supply module compatible with 50-60Hz; DIN Rail module requires stable 24VDC power supply; The signal cable needs to be shielded, and the grounding terminal is only grounded on the amplifier side;

Safety reminder: Before starting the closed-loop system, it is necessary to cut off power and release pressure; First power on, gradually adjust the gain to avoid oscillation/overload; Hydraulic pipelines must comply with pressure specifications to prevent component damage.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923