K-WANG

Woodward MSLC-2XT ™ Main synchronizer and load controller

Woodward MSLC-2XT ™ Main synchronizer and load controller

Product basic information

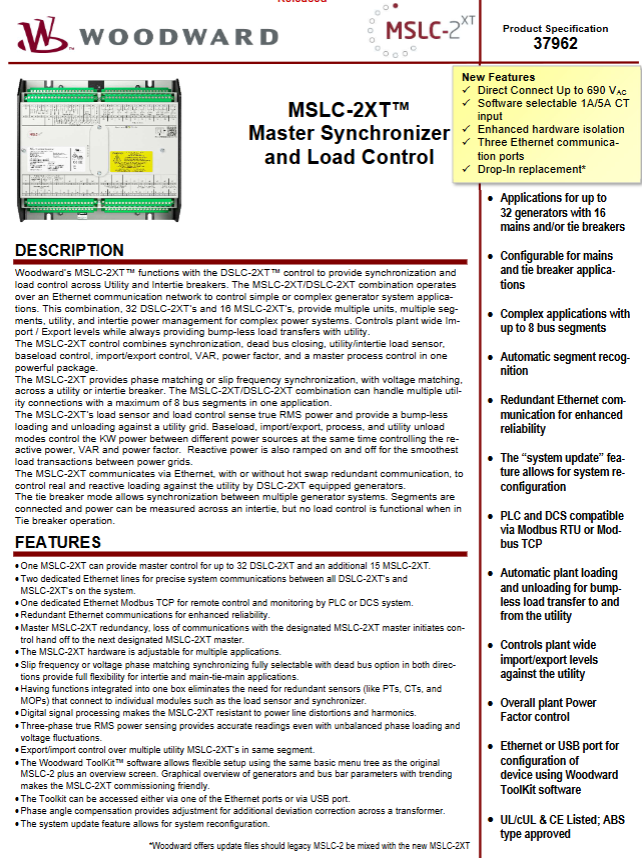

Product Name MSLC-2XT ™ Master Synchronizer and Load Control

Core positioning and DSLC-2XT ™ Cooperate to achieve power system control with multiple generators, multiple segments, and multiple main/connecting circuit breakers

Adapt to complex industrial power systems and ship power systems (ABS/LR classification certification)

Certification qualifications UL/cUL, CE, CSA, EAC, ABS Type Approved, LR Type Approval

Alternative compatibility can directly replace the old version MSLC-2, supporting mixed use of old and new devices (Woodward update file required)

Core functions and features

(1) Synchronization and closing control

Synchronization mode: supports two optional modes: phase matching and slip frequency synchronization

Non voltage busbar closing: Bidirectional support for non voltage busbar closing function, suitable for contact circuit breaker scenarios

Phase angle compensation: It can compensate and correct the phase deviation caused by transformers

Segmented synchronization: supports synchronous control between 8 bus segments and inter segment communication

(2) Power control function

Active power control

Mode: Base load control, import and export power limitation, no impact load transfer (between grid/generator)

Accuracy: Three phase RMS measurement, resistant to voltage fluctuations and three-phase imbalance effects

System level control: capable of controlling the import and export power levels of the entire plant across multiple MSLC-2XT

Reactive power control

Control objects: VAR (reactive power), power factor (PF)

Features: Smooth switching of reactive power to avoid grid impact during load transfer

System level control: supports unified control of power factor throughout the factory

(3) System Expansion and Compatibility

Upper limit of system size

Generator: Up to 32 units (DSLC-2XT required)

Main/contact circuit breakers: up to 16 units

Busbar segmentation: up to 8, supporting automatic segmentation recognition

Communication compatibility

Protocol: Modbus TCP, Modbus RTU

Docking equipment: PLC, DCS system

Configuration interface: 3 Ethernet ports (supporting redundant communication), 1 USB port (local configuration), 1 RS-485 interface

(4) New core features added

Characteristic type, specific content, value

Hardware enhancement directly connects to 690Vac voltage without additional voltage reduction, suitable for medium voltage scenarios

1A/5A CT input software is optional and does not require hardware modifications, suitable for different CT specifications

Enhanced hardware isolation enhances anti-interference capability and ensures stability

Three Ethernet communication ports support redundant communication to enhance reliability

Software enhanced automatic segmentation recognition simplifies complex system configuration

The system update and reconstruction function supports later expansion or reconstruction of the system

ToolKit visualization configuration includes overview page and trend chart, simplifying debugging

Compatibility with old MSLC-2 mixed use to protect existing investments and smoothly upgrade

Key specification parameters

(1) Electrical specifications

Category parameter details

Power supply 12/24VDC (wide voltage 8-40Vdc), maximum power consumption 32W

Voltage measurement software configurable (star/triangle), rated 100-690Vac (line voltage), maximum 897Vac, surge voltage 6.0kV

Current measurement 1A/5A software optional, range 1-32000A (primary), linear range: generator side 3.0 x rated value, grid/ground side 1.5 x rated value

Measurement accuracy: Voltage/current are both at level 0.5

Frequency measurement 50/60Hz (compatible with 30-85Hz)

(2) I/O interface specifications

Interface type specification details

Discrete Input (DI) 23 channels, globally isolated, input range 8-40Vdc, input resistance ≈ 20k Ω

Relay output (DO) 12 channels, galvanic isolated/potential free, AgNi contacts; Universal load 2.0A@250Vac DC load 2.0A@24Vdc / 0.36A@125Vdc / 0.18A@250Vdc

Analog input (AI) 3-channel, non isolated, configurable 0-10V/0-20mA/4-20mA, resolution 14 bits

(3) Environmental and mechanical specifications

Category parameter details

Working environment temperature -40 ° C~70 ° C (-40 ° F~158 ° F)

Storage environment temperature -40 ° C~80 ° C (-40 ° F~176 ° F)

Environmental humidity 95% (no condensation)

Mechanical dimensions (W × H × D) 250 × 227 × 84mm (9.84 × 9.00 × 3.30 inches)

Weight approximately 2480g (5.46 pounds)

Protection level IP20

Installation method: Backboard installation (metal shell)

Configuration and maintenance

Configuration tool: Woodward ToolKit software, supports menu tree configuration, system overview, and parameter trend chart viewing

Configuration interface: ToolKit can be accessed through Ethernet or USB ports

System maintenance: supports the "system update" function, which can achieve system reconstruction or expansion in the later stage

Spare parts support: Provide connector spare parts kit (model 8923-2320), control unit including installation kit (model 8440-2298)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923