K-WANG

Woodward DSLC Digital Synchronizer and Load Controller

Woodward DSLC Digital Synchronizer and Load Controller

Basic Information

Product positioning: Suitable for microprocessor control equipment of three-phase AC generators, replacing traditional analog control

Functional differentiation: Full functional models including VAR/PF control and process control; Simplified functional model: No independent VAR/PF, process control

Suitable for electrical specifications PT configuration: 120/240V star (Y)/open delta; CT rated: primary current compatible with 5A secondary

Power supply requirements: Input voltage of 18-40Vdc (maximum 77Vdc withstand for 5 minutes), power of 18W, maximum current of 1A

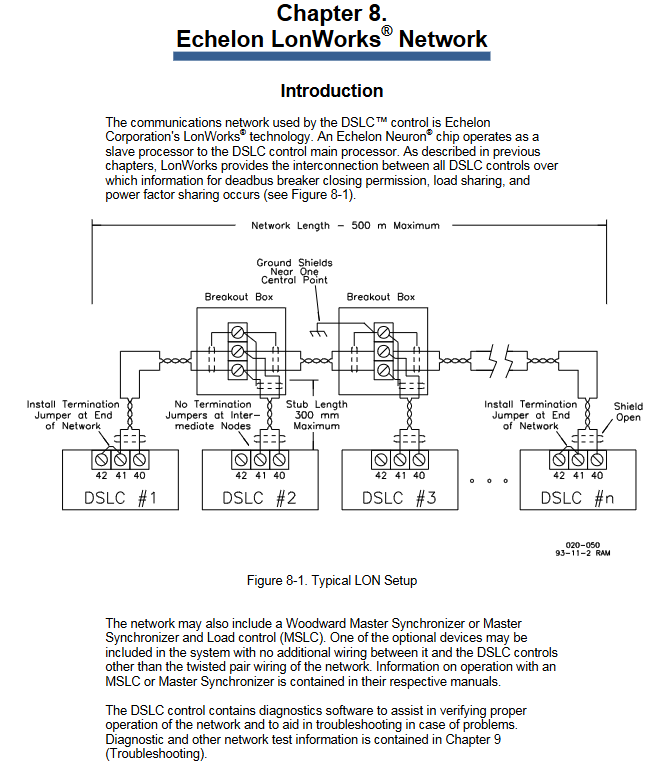

Networking capability supports LonWorks ® Network, communication with up to 16 DSLCs, maximum network transmission distance of 500m

Detailed explanation of core functions

(1) Synchronous control

control mode

Off: Synchronization function disabled; Check: Synchronize matching but do not output closing command; Permissive: only verifies synchronization conditions; Run: Normal synchronization+closing command output

Key functions

Synchronization method: phase matching (fast synchronization, suitable for backup power supply), slip frequency synchronization (ensuring forward power, slip reference 0-0.25Hz)

Non voltage bus closing: Parameters need to be enabled to avoid multiple machines closing simultaneously through network arbitration. Bus voltage below 40Vac is judged as non voltage

Voltage matching: Automatically adjust the generator voltage to the bus voltage window (0-10%), supports enabling/disabling

Core parameters

Parameter Name Setting Range Default Value Unit

Slip frequency reference 0.00-0.25 0.05 Hz

Maximum phase window 2-20 10 °

Circuit breaker delay 0.00-2.00 0.10 s

Closing attempts 1-20 1 times

Voltage window 0.0-10.0 1.0%

(2) Load control

control mode

Core purpose of mode triggering conditions

CB Aux contact disconnection in droop mode, single machine operation or parallel stable

Constant frequency load sharing CB Aux closed+base load/process control disconnected multi machine parallel load sharing

Basic load mode CB Aux+Basic load+Load/UNload Closed fixed load operation

Process Control Mode CB Aux+Load/UNload+Process Control Close Tracking Process Signal

Key functions

Soft loading/unloading: loading time 1-7200s, unloading time 1-7200s, supports slope pause (DI input)

Reverse power protection: instantaneous tripping (-1~-50% load) or delayed tripping (0.1-20s), can be mapped to relay output

Remote load reference: Supports 4-20mA (0-30000kW) or 1-5VDC input, linear interpolation to calculate load target

Core parameters

Parameter Name Setting Range Default Value Unit

Load sag 0.0-100 5.0%

Rated load 0-30000 1000 kW

Unloading trip level 0-30000 0 kW

Loading rate 0.01-100.00 1.00%/s

Reverse power level -1~-50-1.0% load

(3) VAR/PF Control (Full Function Model)

Control mode: disabled (voltage matching only)/PF control (maintaining set power factor)/VAR control (maintaining set reactive power)

Key functions

PF sharing: When multiple machines are connected in parallel, the reactive load is evenly distributed based on the average power factor

Voltage fine-tuning: Maintain the bus voltage within the range of reference value ± voltage regulation rate (1.0-10.0%)

Reactive power limit: The rated kVAR can be set to 60% of the generator kVA (corresponding to a lag PF of 0.8)

Core parameters

Parameter Name Setting Range Default Value Unit

PF reference 0.00 lag -0.00 lead 0.8 lag-

PF dead zone 0.000-1.000 0.025-

Rated kVAR 0-30000 20 (generator side) kVAR

Voltage regulation rate 1.0-10.0 2.0%

Voltage ramp time 1-600 60 seconds

(4) Process Control (Full Function Model)

Adaptation scenarios: cogeneration, power grid import and export control, pressure/liquid level maintenance, etc

Key functions

Signal input: Supports 4-20mA/1-5V process signals, configurable for direct/indirect actions

PID control: proportional gain (0.0001-1000000), integration time (0-20s), dead zone (0-20mA)

Reference adjustment: Local reference (0-20mA) or remote reference (4-20mA), supporting speed adjustment (0.01-20mA/s)

Core parameters

Parameter Name Setting Range Default Value Unit

Process dead zone 0.00-20.00 0.10 mA

Process reference 0.0-20.0 12.0 mA

High limit pickup 0.0-25.0 15.0 mA

Low limit pickup 0.0-25.0 10.0 mA

Process filtering 0.1-5.0 1.0 Hz

Hardware and Communication Configuration

(1) Hardware interface

Key Explanation of Interface Type Quantity/Specification

PT input 3-phase (star/open triangle) 120V (65-150Vac)/240V (150-300Vac)

CT input 3-phase 0-5A rms (maximum 7A), accuracy 0.1% full scale

Discrete Input (DI) 13 channels 18-40Vdc, with a nominal current of 10mA per channel

Relay output (DO) with 8 channels of 200mA current, including circuit breaker closing/opening, alarm and other outputs

Analog input (AI) 2-channel 4-20mA (243 Ω) or 1-5VDC (10k Ω)

Analog output (AO) with 2 speed biases (± 3Vdc/0.5-4.5Vdc, etc.) and voltage biases (± 9Vdc)

(2)LonWorks ® network

Communication speed: 1.25Mbps

Maximum transmission distance: 500m (bus), branch length ≤ 300mm

Number of nodes: up to 64 (0-70 ℃), 20 (-40-85 ℃)

Core functions: Multi machine load sharing, VAR/PF sharing, arbitration of non voltage bus closing authority, remote metering and control

Configuration and Calibration

Configuration tool: Handheld programmer (model 9905-292), supporting 10 major menu operations, including parameter adjustment, calibration, and diagnosis

Key calibration steps

Configuration menu (Menu 5): PT ratio, CT rating, system frequency (50/60Hz), network address (1-16)

Synchronous control calibration: slip frequency, phase window, circuit breaker delay

Load control calibration: load sag, loading/unloading time, reverse power protection parameters

Analog calibration: PT/CT sampling calibration, speed/voltage bias zero calibration

Safety Specifications

Electrostatic protection: Discharge before coming into contact with PCB, and do not touch electronic components

CT protection: The CT wiring cannot be disconnected while the engine is running, and a short circuit is required first

Power protection: The polarity of the power supply cannot be reversed, and the voltage should not exceed 77Vdc

Diagnosis and maintenance

Diagnostic function

Menu 0 (Diagnostics): Self test results (normal is 49), network status (number of active DSLCs, number of transmission errors)

Status monitoring: synchronizer mode, load control mode, alarm status (frequency/voltage/load exceeding limit, etc.)

Common troubleshooting

Possible causes and solutions for the fault phenomenon

Unable to power on, power supply not connected/polarity reversal check 18-40Vdc power supply and polarity

Abnormal power factor display, CT/PT phase reversed, CT/PT phase wiring swapped

Correction of incorrect rated load parameters due to uneven load sharing among multiple machines Menu 2 "Rated Load" is the actual rated power of the generator

Synchronization cannot be closed. The phase window is too small/the circuit breaker delay is improper. Adjust the maximum phase window (≥ 5 °) to match the actual closing time of the circuit breaker

Maintenance support

Repair: Contact Woodward authorized dealer to provide part number, serial number, and fault description

Replacement parts: The part number on the equipment nameplate (such as 9905-355, etc.) needs to be provided

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923