K-WANG

Rockwell ProSoft MVI56-MCM Modbus master-slave communication module

Rockwell ProSoft MVI56-MCM Modbus master-slave communication module

ProSoft MVI56-MCM is a product designed specifically for Rockwell Automation ® ControlLogix ® The Modbus master-slave communication module designed by the processor enables convenient integration between the ControlLogix system and other devices that support the Modbus protocol, such as PLCs, process control devices, and SCADA systems. As an interface module between the Modbus network and the ControlLogix backplane, it has high compatibility, ease of configuration, and reliable communication performance.

Core Features and Advantages

The module meets the flexible communication and efficient operation and maintenance needs in industrial scenarios through targeted design. The core features and corresponding values are as follows:

Characteristics classification, specific characteristics, advantages

Backboard technology authorized by Rockwell Automation; Support 1756 backplane single slot installation (local/remote rack) 1. Implement high-speed data transmission between modules and ControlLogix processors

2. Compatible with ControlLogix system architecture, no additional hardware adaptation required

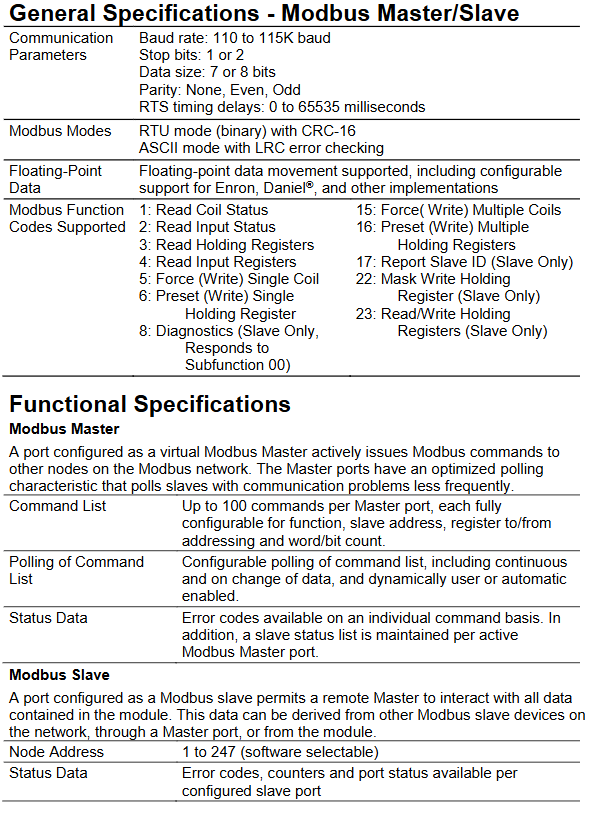

The protocol supports Modbus RTU (binary, with CRC-16 checksum) and Modbus ASCII (with LRC error checksum) protocols; Support floating-point data transmission (including Enron and Daniel) ® 1. Adapt to the communication requirements of different Modbus devices, with wide compatibility

2. Meet the transmission requirements of high-precision data (such as flow and temperature) in industrial scenarios

Configuration and Monitoring 1. Based on RSLogix ™ 5000 configuration, supports viewing module data and status through controller tags

2. Provide example ladder diagrams with complete annotations (including user-defined data types, steps, and labels), which can be used in most scenarios without modification

3. LED diagnostic indicator lights (module status, backplane transmission status, application status, serial activity)

4. Menu driven hardware and protocol diagnostic tools; Support viewing module database content through serial port connection to PC 1. Reduce configuration threshold and shorten deployment time

2. Operations personnel can quickly locate faults (such as communication interruptions, module abnormalities), reducing downtime

20 years of experience in developing industrial communication solutions with technical support and warranty; Global free unlimited technical support (pre-sales, deployment, troubleshooting); 3-year warranty: 1. Ensure long-term stable operation of equipment and reduce maintenance risks

2. Global service network ensures timely access to support and adapts to cross-border project needs

Functional specifications

The module supports both Modbus master and slave modes, allowing for flexible configuration of port roles according to different communication topology requirements.

(1) Modbus master mode

After configuring the port as a master, it can actively send instructions to slave devices in the Modbus network, with intelligent polling and detailed status feedback capabilities:

Instruction configuration: Each master port supports up to 100 configurable instructions, each of which can customize function codes, slave addresses, register read/write addresses, and word/bit counts.

Polling strategy: supports flexible instruction list polling configuration, including continuous polling, polling when data changes, and can be manually or automatically enabled for polling; For slave stations with abnormal communication, the polling frequency will be automatically reduced to optimize network resource utilization.

Status feedback: Provide error codes for individual instructions and maintain a list of slave status for each active master port for troubleshooting purposes.

(2) Modbus Slave Mode

The port is configured to allow remote master access to all data within the module after the slave station (data can come from other Modbus slave stations in the network, master station ports, or the module itself):

Node address: Supports 1-247 software selectable addresses, suitable for multi device networking requirements.

Status monitoring: Each configured slave port provides error codes, counters, and port status data, providing real-time feedback on communication health.

(3) Supported Modbus Function Codes

Covering commonly used read and write operations in industrial scenarios to meet data collection and control requirements:

Function code function description applicable mode (master/slave)

1. Read the status of the coil from the master station (sending) and slave station (responding)

2. Read input status: master station (sending), slave station (responding)

3 Read and hold register master (send), slave (respond)

4. Read input register master (send), slave (respond)

5. Force (write) a single coil master station (send), slave station (respond)

6 preset (write) single hold register master (send), slave (respond)

8 Diagnosis (only supports sub function 00) Only slave station (response)

15. Force (write) multiple coil master stations (send) and slave stations (respond)

16 preset (write) multiple hold registers master (send), slave (respond)

Report 17: Slave ID Only Slave (Response)

22 Block Write Keep Register Only from Slave Station (Response)

23 Read Write Keep Register Only Slave (Response)

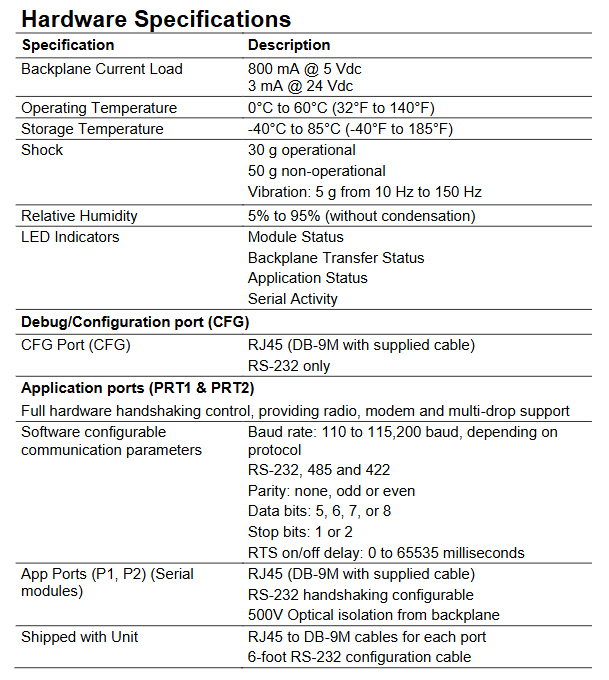

Hardware specifications and interfaces

(1) Basic hardware parameters

Detailed description of specification category

Backboard current consumption: 800mA at 5VDC; 3mA at 24Vdc

Working temperature: 0 ° C -60 ° C (32 ° F -140 ° F)

Storage temperature -40 ° C -85 ° C (-40 ° F -185 ° F)

Impact resistance performance working state: 30g; non working state: 50g

Anti vibration performance 5g at frequencies of 10Hz-150Hz

Relative humidity 5% -95% (non condensing)

LED indicator light module status light, backplane transmission status light, application status light, serial activity light

(2) Interface configuration

The module provides multiple dedicated interfaces to meet configuration, communication, and expansion requirements:

Configure/debug ports (CFG):

Interface type: RJ45 (including matching DB-9M adapter cable)

Communication standard: Only supports RS-232

Purpose: To connect to a PC for module configuration, diagnosis, and database viewing.

Application ports (PRT1&PRT2):

Interface type: RJ45 (including matching DB-9M adapter cable)

Communication standard: Supports RS-232/485/422, with full hardware handshake control (suitable for radio stations, modems, and multi machine networking scenarios)

Communication parameters: baud rate 110-115200 baud (depending on the protocol); Data bits 5/6/7/8; Stop position 1/2; Check bit none/odd/even; RTS switch delay 0-65535 milliseconds (software configurable).

(3) Accompanying accessories

RJ45 to DB-9M cable (1 per port)

6-foot RS-232 configuration cable

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923