K-WANG

Eaton XV-102 Touch Screen Display

Eaton XV-102 Touch Screen Display

Eaton XV-102 is an industrial grade touch display screen that combines HMI (Human Machine Interface) and integrated HMI/PLC functions, suitable for mechanical manufacturing, system integration and other scenarios. It can achieve equipment monitoring, parameter setting and process control, with multiple size models, rich communication interfaces and industrial grade protection performance, and meets multiple international safety and industry certification standards.

Product positioning and core functions

Functional positioning: It can be used as an independent HMI terminal or integrated HMI/PLC device, with the core used for monitoring, operating, and controlling machines and systems in industrial scenarios. It does not support safety functions related to personnel or equipment safety protection.

Applicable scenarios: Mainly aimed at the fields of mechanical manufacturing and system construction, it can also be used in maritime scenarios through classification certification (DNV GL), and must meet specific installation and protection requirements.

Product model and hardware configuration

1. Equipment model classification

XV-102 offers three screen sizes (3.5 inches, 5.7 inches, 7.0 inches) and multiple versions (A/B/D/E/H types), with core differences reflected in display performance, communication interfaces, and expansion functions. The specific parameters are shown in the table below:

Model Version Screen Specification (Size/Resolution/Color) Core Interface Configuration Special Function Model Example

Version A 3.5-inch TFT-LCD (QVGA/32 grayscale) Ethernet USB Device, Optional Profibus/RS232/RS485/CAN 1 SD card slot, no additional expansion XV-102-A2-35MQR

Version B 3.5-inch TFT-LCD (QVGA/32 grayscale or 64K color) Ethernet USB Device, Optional RS232/RS485/CAN/Profibus/SmartWire DT Master 1 SD card slot, supports SmartWire DT Master (some models) XV-102-BE-35TQR

Version D 5.7-inch (VGA/64K color), 7.0-inch (WVGA/64K color) Ethernet USB Device/Host, Optional RS232/RS485/CAN/Profibus 1 SD card slot, large screen compatible with complex interface XV-102-D8-70TWR

Version E 5.7-inch (VGA/64K color), 7.0-inch (WVGA/64K color) Ethernet USB Device/Host, Support RS485+CAN/Profibus+SmartWire DT Master 1 SD card slot, enhance SmartWire DT integration XV-102-E6-57TVR

Version H 3.5/5.7/7.0 inches (64K colors) Ethernet, USB Device/Host (only 5.7/7.0 inches), optional RS232/RS485 basic communication function, suitable for simplified scenarios XV-102-H3-57TVR

Packaging and Accessories

The packaging contents of devices of different sizes may vary slightly, and the core accessories are as follows:

3.5-inch device: 1 touch screen, 4 mounting brackets with top wires, 1 sealing strip, 1 power connector (models with SmartWire DT include an additional SmartWire DT power connector).

5.7-inch device: 1 touch screen, 6 mounting brackets, 1 sealing strip, 1 power connector (models with SmartWire DT include an additional dedicated power connector).

7.0-inch device: 1 touch screen, 8 mounting brackets, 1 sealing strip, 1 power connector (models with SmartWire DT include an additional dedicated power connector).

Optional accessories: 10 touch pens (model ACCESSORIES-TP-TEN-10, item number 139808), need to be ordered separately.

Safety regulations and equipment protection

1. Core security warning

The manual clearly divides the danger level and provides protection requirements. The key warnings are as follows:

Hazard type, risk description, protective measures

Explosion risk: In the potentially explosive environment of Zone 22, disconnecting the live interface or mechanical impact may cause an explosion. It is only used in non hazardous areas or Zone 22; Grounding resistance<10 ΩΩ; Avoid mechanical impact; After power failure, unplug and plug the interface again

There are live parts inside the electric shock risk equipment, and opening the cover may cause electric shock. Do not open the cover by yourself; Only operated by professionals

Static electricity damage: Static discharge may damage electronic components by touching grounded metal before coming into contact with equipment, releasing static electricity; Avoid touching interface pins

Data loss: When reading or writing from an SD card, power failure or unplugging the card may cause data damage. Only when the device is powered off and the SD card is unplugged or unplugged; Reduce SD card write operations (limited write life)

When a sudden change in temperature and humidity caused by a condensation short circuit leads to internal condensation of the equipment, it is forbidden to power on the equipment; Start up after the temperature stabilizes

2. Personnel and operational requirements

Personnel qualifications: Installation and operation personnel need to have industrial automation equipment operation qualifications, be familiar with this manual and relevant safety standards (such as UL 508, IEC/EN 61131-2).

Operating standards: The complete manual must be used (it is prohibited to split a single page for use to avoid missing safety information); Strictly follow the manual requirements for installation, wiring, and maintenance, and unauthorized modification of equipment is prohibited.

Installation and interface configuration

1. Installation requirements

(1) Environmental and location conditions

General requirements: Installed in control cabinets, control panels, or workstations, avoiding direct sunlight (to prevent plastic aging); Vertical installation tilt angle ≤ ± 45 ° (without forced ventilation); Ventilation gap ≥ 3cm (from ventilation opening), ≥ 15cm (from heating components such as transformers).

Special certification requirements:

Maritime Certification (DNV GL): A 24V DC power anti-interference filter must be installed, communication cables must be shielded, and comply with DNVGL-CG-0339 standard.

UL certification: environmental temperature ≤ 50 ℃, pollution level 2; The tightening torque of the power terminal is 0.6-0.8 Nm (5-7 Lb. In).

(2) Installation dimensions and steps

Hole size: 3.5 inches (123 × 87mm ± 1mm), 5.7 inches (157 × 117mm ± 1mm), 7.0 inches (197 × 122mm ± 1mm), installation surface thickness 2-5mm, flatness ≤ 0.5mm, roughness Rz ≤ 120.

Installation steps: Make holes on the installation surface → Paste sealing strips (the joint should be at the bottom of the equipment without gaps) → Insert the equipment from the front → Fix with corresponding numbers of brackets (4 in 3.5 inches, 6 in 5.7 inches, and 8 in 7.0 inches, ensuring IP65 protection), and tighten the bracket top thread with a torque of ≤ 0.1 Nm (to prevent damage to the equipment).

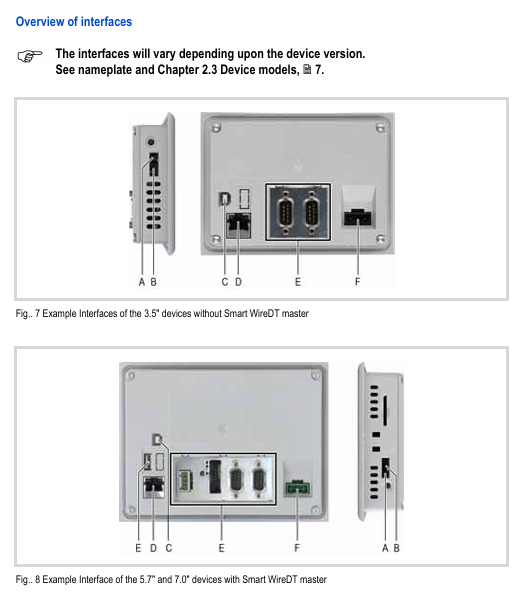

2. Interface configuration and wiring

XV-102 provides rich industrial interfaces, supporting multi protocol communication and expansion. The core interface parameters are as follows:

Interface type specifications and functional wiring requirements

Power interface 24V DC SELV (safe ultra-low voltage), voltage range 19.2-30V DC, maximum power consumption of 5W for 3.5-inch, maximum 9.5W for 5.7/7.0-inch, using Phoenix MSTB 2.5/3-ST-5.08 connector (built-in); XT-FIL-1/2 anti-interference filter needs to be installed (for maritime/EMC B-level scenarios)

Ethernet 100Base TX/10Base-T (RJ45), supporting LED status indication (ACT flashing=data transmission, LINK constantly on=network connection) using shielded twisted pair (STP); Cross wires are used between devices, and straight wires are used to connect to switches; Maximum length 100m

RS232 (system port) 9-pin D-Sub male, non isolated, supports up to 115200 bit/s (within 2.5m) with shielded cable; The cable length is negatively correlated with the baud rate (e.g. ≤ 9600 bit/s at 30m); The GND terminal must be connected

RS485 9-pin D-Sub male, non isolated, supports 32 slave stations, and requires 120 Ω terminal resistors at both ends of the bus using shielded twisted pair cables; Maximum length 500m (0.75mm ² wire diameter); The GND terminal must be connected

CAN 9-pin D-Sub male head, non isolated, compliant with CiA standard, supports 32 shielded twisted pair cables with characteristic impedance of 120 Ω for slave stations; Maximum length of 5000m (at 10 kbit/s); Terminal resistors are required at both ends of the bus

Profibus 9-pin D-Sub female head, non isolated, up to 1.5 Mbit/s (within 200m) using Profibus Class A shielded twisted pair (impedance 150 Ω); Terminal resistors are required at both ends of the bus; 5V pin prohibits external power supply

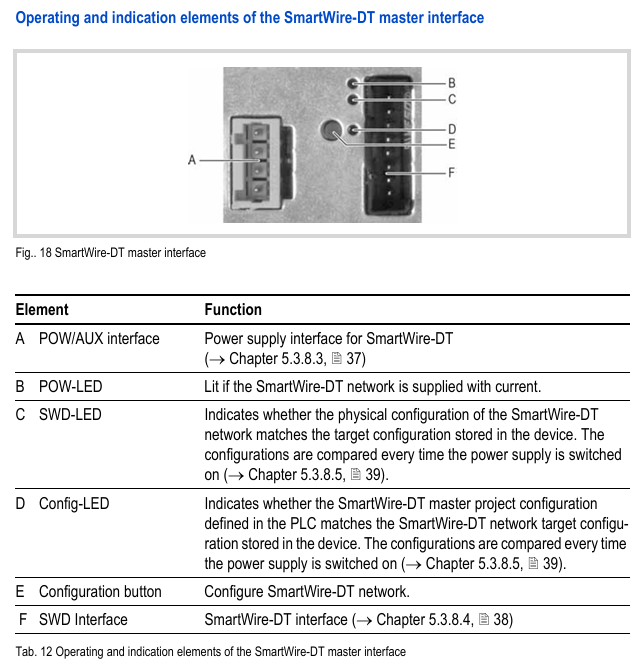

SmartWire DT Master 8-pin interface (SWD)+POW/AUX power interface, non isolated, supports up to 99 SWD modules with dedicated SWD cables (such as SWD4-100LF8-24); UAUX requires external 2A circuit breaker (UL standard) or 3A fuse (DIN standard)

USB USB 2.0(Device Type B/Host Type A), Non isolated shielded USB cable; Maximum length of 5m; Host interface supports external devices such as USB drives

Operation and Maintenance

1. Basic operations

Power on and off: No physical switch, automatically boots when powered on, shuts down when powered off; For the first startup, please refer to the "Windows CE System Instructions" (MN05010007Z) to configure system parameters and install applications.

SD card operation: Only plug and unplug when the device is powered off; Used to store project files or data, avoiding frequent writes (limited lifespan); Power off is prohibited during reading and writing.

Touch calibration: It has been calibrated at the factory. If there is an abnormal response, it needs to be recalibrated using system tools (refer to the "Windows CE System Instructions"); Operate only with fingers or a dedicated stylus, and avoid touching with sharp objects (to prevent damage to the resistive screen).

2. Maintenance and troubleshooting

(1) Daily maintenance

Cleaning: Use a clean, soft, and damp cloth to wipe the resistance screen. For stubborn stains, dip a small amount of detergent in it; Do not use sharp tools, corrosive solvents, or liquids to infiltrate the equipment.

Battery maintenance: Built in CR2032 lithium battery (3V/190mAh), non replaceable, can maintain real-time clock for about 10 years after power failure.

Repair restriction: Self opening repair is prohibited. Contact Eaton authorized repair center or supplier.

(2) Common fault handling

Possible causes and solutions for the fault phenomenon

The device cannot start and the power supply is not properly connected or the voltage is abnormal. Check the 24V DC power supply wiring; Confirm that the voltage is within the range of 19.2-30V DC

Touch screen unresponsive/response deviation touch screen not calibrated; Install the bracket too tightly and recalibrate the touch screen; Loosen the top wire of the bracket (torque ≤ 0.1 Nm)

Display screen black, backlight not activated or malfunction check, backlight settings in visualization software; Fault needs to be returned to the factory for repair

Communication interruption (such as Ethernet/CAN) cable not connected properly; Terminal resistor missing; Interference check cable wiring; Confirm the connection of 120 Ω terminal resistors at both ends of the bus; Install anti-interference filter or magnetic ring

Technical parameters and compliance certification

1. Core technical parameters

Parameter category specification

Display performance of 3.5 inches (QVGA/32 grayscale/64K color), 5.7 inches (VGA/64K color), 7.0 inches (WVGA/64K color); The lifespan of LED backlight is about 40000 hours, and the brightness can be adjusted by software

System configuration: 32-bit RISC processor (400MHz); 64MB DRAM + 64MB NAND Flash; Some models include 125KB NVRAM

Protection level: IP65 on the front (requires correct installation of brackets), IP20 on the back

Environmental adaptability: working temperature 0-50 ℃, storage temperature -20-60 ℃; Relative humidity ranging from 10% to 95% (without condensation); Anti vibration (5-150Hz, 2g), anti impact (15g/11ms)

Power supply characteristics: 24V DC SELV, with reverse polarity protection and built-in fuses; Start impulse current 1.5A/2s

2. Compliance certification

Safety and EMC: Compliant with UL 508 (Industrial Control Equipment), UL 60950 (Information Technology Equipment), CE (EMC Directive 2014/30/EU); ATEX 2014/34/EU (Zone 22, 3D explosive environment).

Industry certification: DNV GL classification certification (TAA00000NC), suitable for maritime scenarios; Compliant with IEC/EN 61131-2 (Requirements for PLC Equipment) and EN 50178 (Electronic Equipment for Power Installation).

Storage, transportation, and disposal

Storage: ambient temperature -20-60 ℃, relative humidity 10% -95% (no condensation); Avoid direct sunlight, vibration, and chemical corrosion.

Transportation: Use original packaging to avoid impact and compression; The transportation environment must meet the storage conditions, and upon arrival, inspect for any transportation damage.

Disposal: The equipment contains lithium batteries (CR2032, containing 1.2-dimethoxyethane), which need to be professionally disposed of according to local environmental standards or returned to Eaton for disposal; The packaging materials (cardboard, PE bags) are recyclable.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923