K-WANG

YOKOGAWA MY600 Digital Insulation Resistance Tester

YOKOGAWA MY600 Digital Insulation Resistance Tester

Product positioning and core functions

MY600 is a compact digital insulation resistance tester designed to measure the insulation resistance of electrical equipment or circuits. It supports voltage measurement (AC/DC) and low resistance on/off inspection, and is portable, high-precision, and adaptable to multiple scenarios. It is widely used in fields such as power equipment maintenance, electrical installation acceptance, and industrial circuit testing.

Packaging and Accessories

1. Standard accessories (included with the product)

After opening the box, it is necessary to confirm that the following accessories are intact. If they are missing or damaged, please contact the Yokogawa distributor:

Accessory Name Model/Part Number Quantity Usage

Portable case 93045 1 for storing instruments and accessories, easy to carry

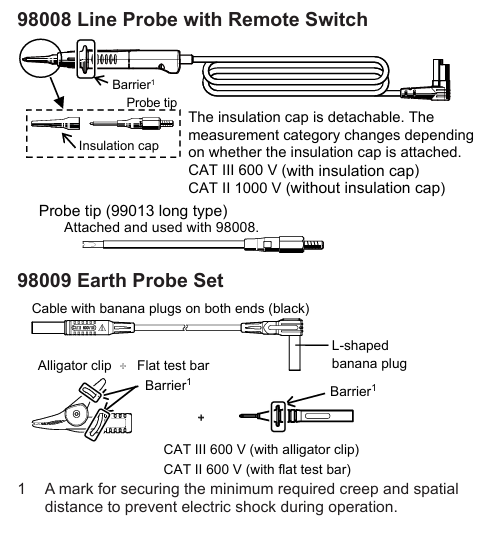

Line probe with remote switch 98008 1 connected to LINE terminal for line side measurement

Grounding probe group 98009 1 is connected to the EARTH terminal for measuring the grounding side

Shoulder strap 99018 1 hanging instrument, supports dual hand operation

Alkaline dry battery -4 instrument power supply (AA alkaline battery recommended)

User manual set IM MY600-01EN/92Z1/00C01C01-01Z2/PIM113-01Z2, each containing multilingual instructions and global contact information

2. Optional accessories (to be purchased separately)

According to the requirements of the measurement scenario, it is necessary to ensure that the accessories meet the rated parameters of the instrument:

Accessory Name Model/Part Number Usage

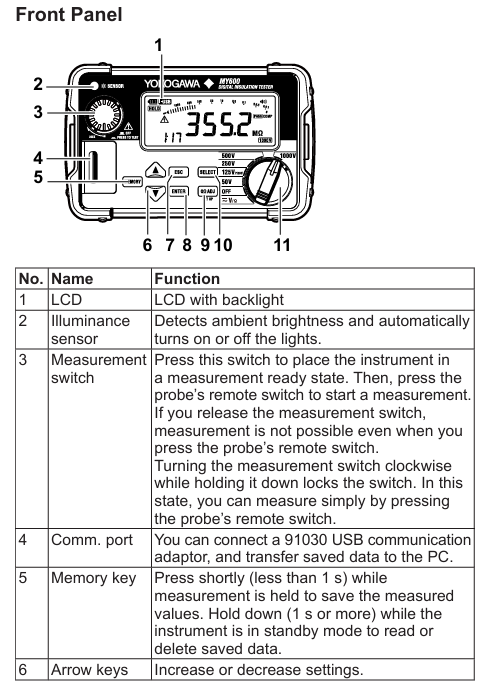

USB communication adapter 91030 is used to connect to a PC and transfer measurement data from memory

Hook probe tip 99012 replaces standard probe, suitable for special wiring scenarios

Long probe tip 99013 deep into narrow spaces for measurement, expanding measurement range

Safety regulations

1. Core safety warning (to avoid electric shock/equipment damage)

Laser and high voltage protection: When measuring insulation resistance, there is high voltage at the tip of the probe, and touching the probe or the tested circuit is prohibited; After measurement, wait for automatic discharge to complete(“ ⚠️” Symbol flashing+buzzing), then touch the circuit.

Measurement category restriction: The rated measurement category of the instrument is CAT III 600V, and it is prohibited to use it for CAT IV or main power circuits exceeding 600V; When the probe is paired with different accessories, the category is different (for example, 98008 with insulation cap is CAT III 600V, and without cap is CAT II 1000V).

Requirements for the tested equipment: Before measurement, the power supply of the DUT must be cut off, and the voltage measurement function must be used to confirm that there is no power before starting; Do not measure live circuits to avoid instrument damage or electric shock.

Equipment status check: If the instrument casing is damaged, the probe cable is exposed, or the battery compartment is damp, use is prohibited; After falling or colliding, it is necessary to contact the dealer for maintenance to avoid insulation protection failure.

2. Operation safety rules

Battery replacement: Before replacing, power off and remove the probe. It is forbidden to open the battery compartment during measurement; New batteries of the same type should be used to avoid mixing old and new/different models.

Environmental restrictions: Do not use in flammable gas, humid (with condensation) or outdoor rainy environments; Working temperature range -10~+50 ℃, storage temperature -20~+60 ℃, avoid direct sunlight.

Probe usage: Only Yokogawa designated probes can be used, damaged or aged probes should be replaced in a timely manner; Before connecting/disassembling the probe, it is necessary to disconnect it from the device being tested.

Core functions and operating procedures

1. Measurement mode and parameters

The instrument supports three core measurement modes, and the parameters and applicable scenarios for each mode are as follows:

(1) Voltage measurement (AC/DC automatic detection)

Range and Range: Automatic range (300.0V/600V), measurement range AC 2.0~600V (45~65Hz), DC ± 2.0~± 600V, over range display ">629V" (AC/positive DC) or "<-629V" (negative DC).

Accuracy: ± 1% reading ± 4 digits (23 ℃± 5 ℃, RH ≤ 80%), AC detected using true RMS, non sinusoidal (CF<2.5) requires an additional ± 1% error.

Operation steps:

Connect the line probe (98008) to the LINE terminal, and connect the ground probe (98009) to the EARTH terminal.

Set the range switch to "V/Ω" and connect the probes to the line side and ground side of the tested circuit.

No need to press the measurement switch, the instrument automatically detects AC/DC and displays the value (triggering a live warning when ≥ 30V:“ ⚠️” Blinking and buzzing.

(2) Insulation resistance measurement (core function)

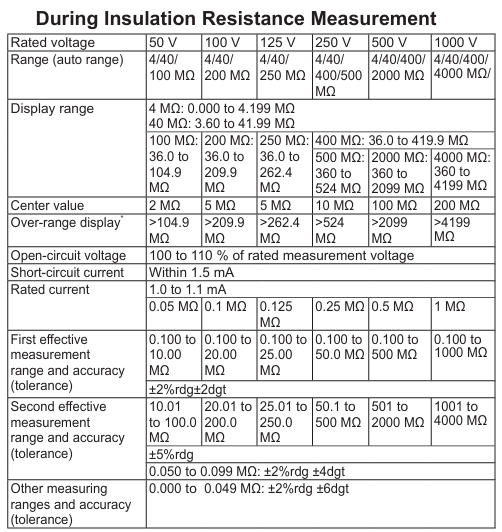

Rated voltage and range: Supports six rated voltages of 50V/100V/125V/250V/500V/1000V, with automatic range switching (such as 1000V range of 4~4000M Ω), and a fixed value displayed for exceeding the range (such as>4199M Ω).

Key parameters:

Open circuit voltage: 100-110% of rated voltage.

Short circuit current: ≤ 1.5mA (1000V range) to ensure measurement safety.

Accuracy: First effective range (such as 1000V range 0.100~1000M Ω) ± 2% reading ± 2 digits; Second effective range (1001~4000M Ω) ± 5% reading.

Featured Features:

Automatic discharge: After measurement, keep the probe connected, and the instrument will automatically release the charge of the measured capacitor load. Before the discharge is completed“ ⚠️” Flashing and buzzing.

Pass/Tail judgment: A reference value (0.001~4199M Ω) can be set. When the measured value is ≥ the reference value, the backlight flashes green and "PASS", otherwise it flashes red and "FAIL".

DAR/PI calculation: Automatically calculate the dielectric loss absorption ratio (DAR=1 minute value/15 second value) and polarization index (PI=10 minute value/1 minute value), ranging from 0.00 to 9.99, with ">9.99" displayed if out of range.

Operation steps:

Connect the probe, confirm that the tested device is powered off, and verify that there is no power using voltage measurement.

Turn the range switch to the corresponding rated voltage level (long press SELECT to switch between 125V/100V levels).

Connect the probe to the device under test, and simultaneously press the instrument's "measurement switch" and the probe's "remote switch" to start measuring (continuous measurement requires locking the measurement switch).

After the measurement is completed, wait for the automatic discharge to end before removing the probe.

(3) Low resistance measurement (on-off check)

Range and Range: Automatic Range (40.00 Ω/400.0 Ω/4000 Ω), Measurement Range 0.00-4199 Ω, Over Range Display ">4199 Ω".

Key parameters:

Open circuit voltage: DC 4~6.9V.

Measurement current: below 2 Ω ≥ 200mA, when the current is ≥ 200mA, a buzzer will sound to indicate on/off.

Accuracy: 0.20-4000 Ω± 2.5% reading ± 8 digits; 0~0.19 Ω± 8 digits (0 Ω calibration needs to be performed first).

Featured feature: 0 Ω calibration (can counteract probe and fuse resistance, up to 3 Ω), ensuring low resistance measurement accuracy.

Operation steps:

Turn the range switch to "V/Ω" and press SELECT to switch to low resistance mode.

Short circuit the probe, long press the "0 Ω ADJ" button to perform calibration (display "0.00 Ω" and light up the "0 Ω" indicator light).

Connect the probe to the tested circuit, press the measurement switch, and display the resistance value (beep when the current is ≥ 200mA).

2. Auxiliary functions

Backlight and LED lights: The illuminance sensor automatically detects the ambient brightness, automatically turns on the backlight and measurement point LED lights when dim, and automatically turns off after 2 minutes of inactivity; It can also be manually set to be normally off.

Automatic shutdown: Automatic shutdown after 10 minutes of inactivity (disabled during measurement or when the measurement switch is locked), with a warning beep before shutdown.

Clock settings: Year/month/day/hour/minute can be set, measurement data is automatically associated with timestamps, and there is a built-in lithium battery backup clock (with a lifespan of about 10 years).

Memory function: can store 1000 sets of measurement data (voltage/insulation resistance/low resistance), including DAR/PI, time, range and other information; Support data viewing and deletion (single/all), and transfer to PC through USB adapter.

System Settings and Data Management

1. Function configuration (long press SETUP to enter configuration mode)

Pass/Tail reference value: Set the judgment threshold for each voltage level, supporting preset values (such as default 0.5M Ω for 500V level) or custom values (0.001-4199M Ω).

Backlight/LED lights: Set to "ON" (automatic start stop) or "OFF" (normally off).

Buzzer: Set "ON" (live warning, discharge, on/off prompt) or "OFF" (turn off all beeps).

Clock calibration: Adjust the year/month/day/hour/minute to ensure accurate data timestamps.

2. Data management

Storage: When holding the measurement value, press the MemoRY button briefly to set the site number (SITE No.1/2, 0~99) and data number (automatically increasing) to complete the storage.

View: Press and hold the Memory button during standby time, select the data number using the directional keys, and view the measured values and station information.

Delete: When viewing data, select the number (or "ALL") and press ENTER to confirm the deletion (single or all).

Transmission: Connect to the PC via USB communication adapter (91030), install the driver, and export data using commands (refer to IM 91030-01EN manual).

Maintenance and repair

1. Daily maintenance

Battery management: When the battery level is low, the "battery icon" displays "empty" and needs to be replaced in a timely manner (4 AA alkaline batteries); Long term disuse requires removing the battery to avoid leaking and damaging the instrument.

Cleaning: Wipe the outer shell with a dry soft cloth, and do not use abrasives or solvents; The surface of the illuminance sensor needs to be kept clean to avoid affecting the automatic backlight/LED function.

Calibration cycle: It is recommended to calibrate once a year to ensure measurement accuracy. Calibration must be performed by Yokogawa certified personnel.

2. Fault handling and maintenance

Frequently Asked Questions:

Inaccurate measurement value: Check the battery level, probe connection, and perform 0 Ω calibration again for low resistance measurement.

Backlight/LED not on: Clean the illuminance sensor or manually confirm that the configuration mode is set to "ON".

Unable to store data: Memory is full (old data needs to be deleted), or the operation was not in the 'measurement value hold' state.

Maintenance restrictions: It is prohibited to disassemble the instrument by oneself (only battery replacement can open the battery compartment). For internal faults, please contact the Yokogawa dealer. Repairs involving safety insulation components require professional operation.

3. Disposal and Compliance

Equipment disposal: When disposing of equipment, local laws and regulations must be followed, and batteries (alkaline batteries and built-in lithium batteries) must be separated and classified for disposal.

Environmental Compliance: Compliant with EU RoHS Directive, WEEE Directive (prohibiting the mixing of household waste in EU regions), and EU Battery Directive (batteries must be recycled separately).

Product Specifications

Appearance dimensions: 156 (W) × 46 (H) × 97 (D) mm, weight approximately 490g (including battery).

Factory default settings: such as Pass/Tail reference values for each voltage level (0.5M Ω for 500V level), default "ON" for backlight/buzzer, default clearing of memory, etc.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923