K-WANG

GE Mark VIe Control System

GE Mark VIe Control System

Introduction

The Mark VIe control system is a flexible platform suitable for various application scenarios, with high-speed networked input/output (I/O) functionality, supporting simplex, dual, and triple redundant systems. It adopts industry standard Ethernet communication for connecting I/O, controllers, operators and maintenance stations, as well as third-party systems. The ControlST software suite (including the ToolboxST toolset) is used for programming, configuration, trend analysis, and diagnostics of the system, providing high-quality, time consistent data at the controller and factory levels to assist in effective management of control system equipment. In addition, the Mark VIeS safety control is an independent safety control system suitable for safety critical applications that comply with the IEC 61508 standard. It also uses the ControlST software suite to simplify maintenance, but has unique certified hardware and software modules.

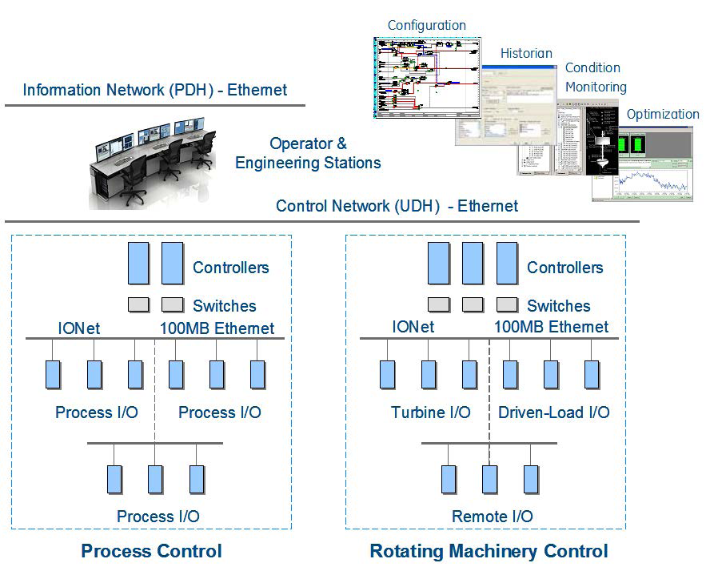

System Overview

Core components: With a single board controller as the core, it includes a main processor, redundant Ethernet drivers for communicating with networked I/O, and additional Ethernet drivers for controlling the network. The main processor and I/O modules adopt a real-time multitasking operating system, and the control software is stored in non-volatile memory in a configurable control block language. It also supports IEEE 854 32-bit floating-point format and Sequential Function Chart (SFC).

I/O Network (IONet): It is a dedicated full duplex point-to-point protocol that provides a deterministic high-speed 100MB communication network, suitable for local or distributed I/O devices, supports single, dual, and triple redundancy configurations, and also supports copper and fiber optic interfaces.

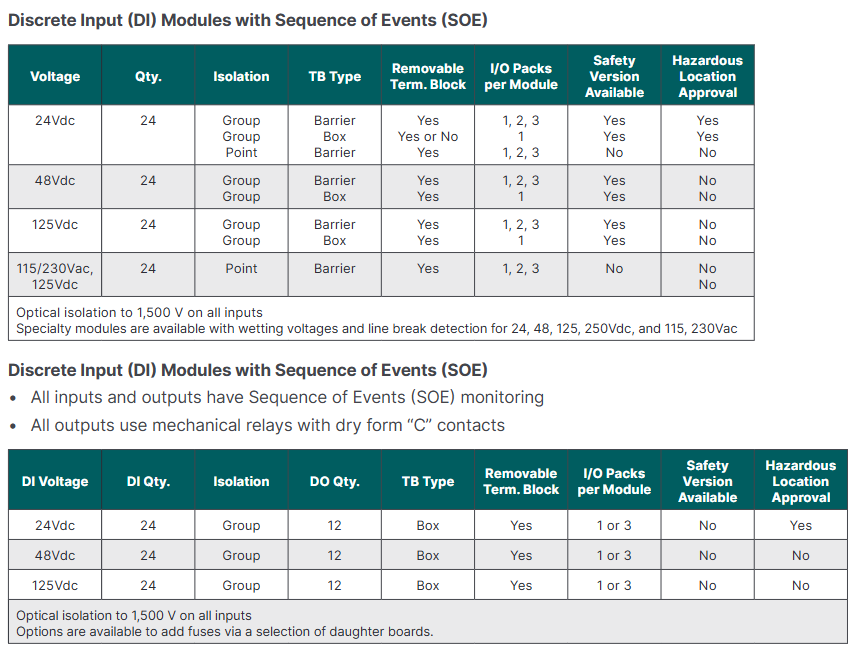

I/O module: It consists of three parts: terminal board, terminal block, and I/O package. There are two types of terminal boards: T-type and S-type. T-type usually assigns inputs to three independent I/O packs, while S-type provides a set of screws for each I/O point. The I/O packet contains two Ethernet ports, a power supply, a local processor, and a data acquisition board, which can be added according to application requirements to expand I/O capabilities. It supports simplex, dual, or triple redundant configurations.

Redundant configuration: Provides multiple redundancy options for processes with different levels of criticality, involving multiple control components such as power supply, power supply, I/O pack, Ethernet port, IONet, and control network. The dual redundant system transmits inputs to dual controllers through dual IONets, while the triple redundant system processes faulty components through 2-out-of-3 logic selection or median selection.

Temperature rating: The operating temperature range of electronic devices such as controllers, I/O modules, and power supplies is -30 to 65 ° C (-22 to 149 ° F), with some fieldbus solution modules having slightly reduced operating temperature ranges. During transportation and storage, the temperature range for controllers and other equipment is -40 to 85 ° C (-40 to 185 ° F), while for control room equipment it is 0 to 30 ° C (32 to 86 ° F).

Controller: Compact and flexible design, with multiple frame rate options, different processor speeds, multiple Ethernet, USB, and COM ports, supports simplex, dual, and triple configurations, power supply of 18 to 32V DC, no battery, with status LED, specific cooling method, in compliance with IEC-61508 safety standards, Achilles Level 1 safety certification, operating temperature varies by model, humidity is 5 to 95% non condensing.

Network Security: As a global leader in automation and control, GE regards network security management as an inherent feature of the Mark VIe control series, including network security enhanced control system components, top-notch security features, and software patch services. Security measures include security configuration, secure network architecture (three-layer protection), role-based access control, enhanced control systems, etc. Both controllers and HMI operations have corresponding security protection mechanisms, as well as functions such as security information and event management (SIEM), antivirus patch management, and security patch services.

ControlST software suite

Composition: Includes WorkstationST HMI and history management application, ToolboxST configuration and diagnostic application, and CIMPLICITY graphical tool, suitable for various control applications of GE.

Human Machine Interface (HMI): A Windows based operator station and engineering workstation that can be used as an independent operator station, engineering workstation only, or both, with options for commercial and industrial grade computers. Communication is carried out through Ethernet control networks and separate Ethernet information networks, supporting redundant HMIs and Ethernet networks to improve reliability. Key control and protection functions are processed in the controller, which also performs high-precision time stamping and maintains alarm status.

WorkstationST HMI and Historical Recording Software: Provides a foundation for operator experience, integrates graphical tools, and can manage control system functions such as alarms, events, logs, historical data, networks, and web interfaces. It has functions such as alarm server and viewer, multiple OPC servers, internal and external history recording interfaces, HMI configuration, device manager gateway, Modbus communication, network time protocol (NTP), and user role security system.

ToolboxST Configuration and Diagnostic Application: Provides a universal configuration tool for hardware and software from I/O modules, controllers to operator stations, simplifying system configuration and enhancing troubleshooting capabilities through advanced diagnostic tools. It has key functions such as software editor, trend analysis, block chart, specific application block library, configuration management system, hardware and software configuration, diagnostic display and message, and search tool.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923