K-WANG

Zygo Device Standard Operating Procedure (SOP)

Emergency operation: If an abnormality occurs, immediately press the "Emergency Off" button on the motion controller, and the device will need to perform the "Homing" operation again in the future.

Zygo Device Standard Operating Procedure (SOP)

Core operating prerequisites and safety warnings

Core safety mechanism: The Z-axis limit (Z-stop) of the Motion Controller is a critical safety protection, and it must be confirmed that it has been set (the indicator light is constantly green or red) before all measurement steps to prevent collision between the objective lens and the sample/stage.

Emergency operation: If an abnormality occurs, immediately press the "Emergency Off" button on the motion controller, and the device will need to perform the "Homing" operation again in the future.

Complete operational process

1. Startup and initialization (Start Up)

(1) Inspection of motion controller

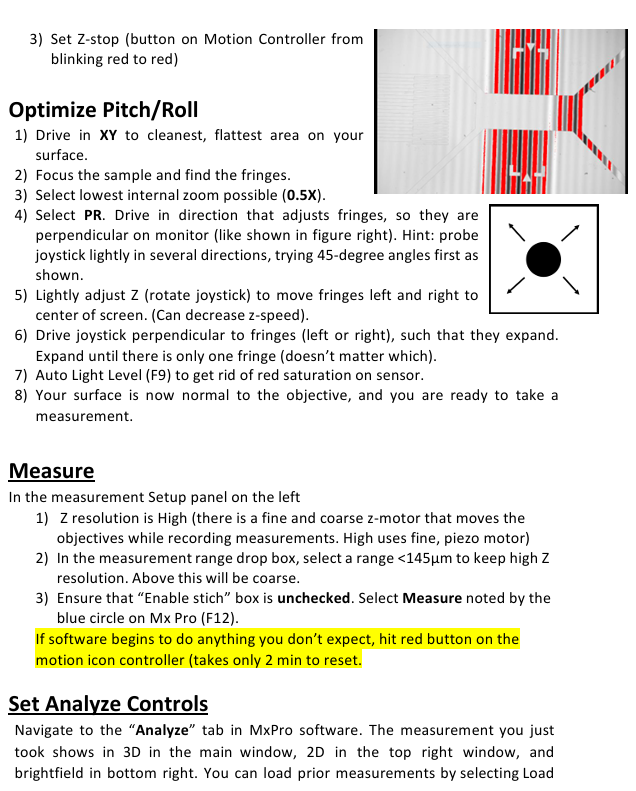

Confirm Z-stop status: The indicator light should be constantly on green/red. If it flashes red and accompanied by a beep, it needs to be reset (detailed steps to follow).

Familiar with controller functions:

Precautions for functional operation mode

When the Z-axis objective lens moves and rotates the Joystick near the sample or at high magnification, use low speed (adjusted by the "+/-" keys)

XY axis stage movement tilt control lever (need to select the "XY" button, corresponding green light on) is used for rough positioning of the sample to ensure that the objective beam is projected onto the sample

Pitch/Roll (P/R) adjustment tilt control lever (the "PR" button needs to be selected, corresponding green light is on) P (pitch), R (roll) maximum adjustment range ± 2 °, θ (rotation) function is invalid

(2) Software startup and application loading

Login to the computer: Enter the username "Zygo" and press Enter to enter the system.

Open the Mx software: Start the Mx program from the desktop, go to "File" ->"Load Application", and load the "Micro. appx" application (the application list also includes other. appx files such as roughness measurement and low-pass filtering, which need to be selected accurately).

Instrument parameter initialization: After loading the application, a "F-stop/A-stop" setting window will pop up. Please confirm:

F-stop (aperture): in the "Open" state (locked by pressing the knob);

A-stop (aperture stop): in the "Open" state (locked by pressing the knob);

Filter: Set to "F1 (Measure)", click "OK" to confirm.

2. Sample and objective lens preparation

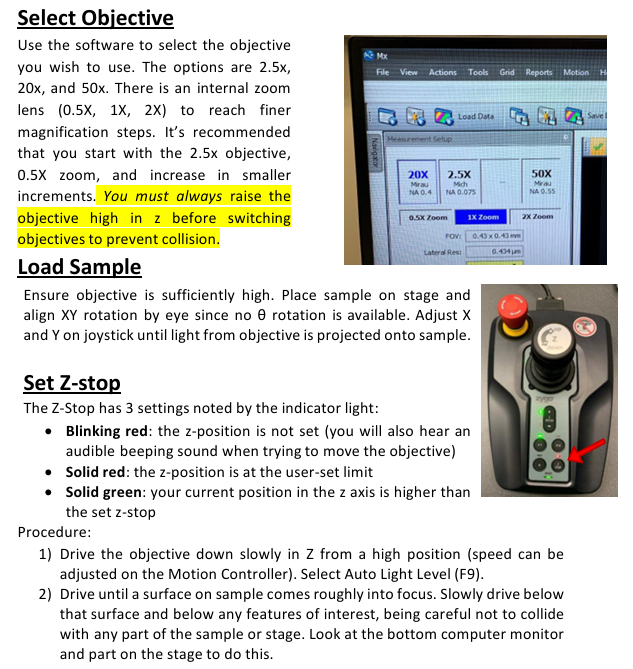

(1) Objective selection and switching

Optional objective lenses: 2.5X (NA 0.075), 20X (NA 0.55), 50X, paired with an internal zoom lens (0.5X/1X/2X) for fine magnification adjustment.

Switching principle:

Initial recommendation is to use a "2.5X objective lens+0.5X zoom" and gradually increase the magnification (to avoid collisions caused by using high magnification directly);

Before switching the objective lens, it must be raised to the highest position along the Z-axis to prevent collision with the sample.

(2) Load Sample

Confirm that the objective lens has been raised to a high position and place the sample on the stage;

Roughly adjust the XY direction rotation of the sample with the naked eye (the device does not have a θ rotation function);

Tilt the XY joystick and move the stage until the beam emitted by the objective lens is projected onto the surface of the sample.

(3) Z-stop setting (core security steps)

Slowly lower the objective lens from the Z-axis high position (adjust the controller speed, slightly faster in the initial stage, and slow down when approaching the sample), press "F9" to start "Auto Light Level";

Continue to lower the objective lens until the sample surface is roughly in focus, and then slowly lower it to the position of "all features below the target measurement area" (combined with the display below and visual observation to avoid collision);

Press the "Z-stop" button on the motion controller, and the indicator light will change from flashing red to constantly on red, completing the setting (at this time, the lowest position of the Z-axis is locked).

3. Calibration before measurement (optimizing pitch/roll)

By adjusting the P/R (pitch/roll), ensure that the sample surface is perpendicular to the objective lens. The steps are as follows:

Move the XY stage to move the "smoothest and cleanest area" of the sample directly below the objective lens;

Focus on the sample and find the interference fringes, switch to the lowest internal zoom (0.5X) for easy observation of the fringes;

Select the "PR" button (green light on), lightly touch the joystick (try 45 ° direction first), and adjust the stripes to be perpendicular to the monitor;

Fine tune the Z-axis (rotate the joystick to reduce speed) and move the stripes to the center of the screen;

Tilt the joystick in the direction perpendicular to the stripes to expand them until only one stripe remains on the screen (direction not limited);

Press "F9" again to perform automatic light intensity adjustment, eliminate sensor red saturation, and complete calibration.

4. Perform Measurement

(1) Measurement parameter settings

Configure in the left "Measurement Setup" panel:

Z resolution: set to "High" (enable fine piezoelectric motor to ensure accuracy);

Measurement Range: Select a range of<145 μ m (if exceeded, it will automatically switch to coarse precision mode);

Enable Stitch function: Uncheck (default off to avoid multi area stitching errors).

(2) Start measurement

Click the blue "Measure" button in the Mx software (or press "F12");

Exception handling: If the software performs an unexpected operation, immediately press the red emergency button on the motion controller to reset the device (approximately 2 minutes).

5. Data Processing (Set Analyze Controls)

After the measurement is completed, the data will be displayed in "3D view (main window), 2D view (upper right window), bright field image (lower right window)", and horizontal correction needs to be performed through post-processing:

(1) 2D horizontal correction (applicable for profile analysis)

Right click on the 3D image in the main window and select "2D" to switch views;

Select the "Linear" option at the top of the window, click on two points on the image, and determine the profile to be analyzed (the profile curve will be automatically generated below);

Right click on the profile curve and add "Inspector 1" and "Inspector 2" in sequence;

Move the Inspector to the baseline surface, right-click and select "Level" to complete the calibration.

(2) 3D horizontal correction (applicable to overall surface analysis)

In the "Surface" panel on the left, click on "Surface Processing" (a settings window will pop up);

Check the "Immediate Update" and "Use Fit Mask" options in the bottom left corner, and click on "Mask Editor";

Check 'Form Remove' and draw a geometric shape to frame the surface shape to be removed (such as protrusions and depressions);

Close the "Mask Editor" and "Surface Processing" windows, and the correction effect will be automatically applied to the 3D data.

6. Save Results&Clean Up

(1) Save Results

Raw data (. datax format): Use "File" → "Save Data" to save to the "Data (D:) ZygoData" folder on drive D;

Image/Table Export: Right click on any chart and select "Export" to export the image as an image format or the 2D section as a. csv file.

(2) Shutdown process

Raise the objective lens: Raise the objective lens to the highest position along the Z-axis and reset the Z-stop (press the button until the indicator light stays on in red);

Software and System Shutdown: Close the Mx software, exit the "Zygo" account, and turn off the monitor;

Record and report: Sign in the experimental log book. If any errors occur during use, take a screenshot and save it to the data folder, and indicate the fault situation in the log.

Key precautions

Collision protection: All operations involving Z-axis movement (switching objectives, loading samples, setting Z-stop) must ensure sufficient safety distance between the objective and the sample, and prioritize the lowest speed when high magnification (50X);

Magnification selection logic: Starting from low magnification (2.5X+0.5X), gradually increasing to avoid using high magnification directly causing "sample not found" or collision;

Data storage standard: The. datax original file should be named with "sample name+date", and screenshots and. csv files should be associated with the original data for easy traceability in the future;

Priority of exception handling: In case of equipment failure, press the emergency button first, and then record the fault phenomenon (screenshot+text description). It is prohibited to disassemble or modify software parameters by oneself.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923