Baldor sports product accessories

This document focuses on Baldor brand sports product accessories, covering core categories such as HMI panels, various cables, 24V DC DIN rail power supply units, EMC filters, encoder distributors, etc. All accessories are specifically designed to fit Mint under Baldor ® The design of main products such as programmable motion controllers and servo drives has the characteristics of strong compatibility, stable performance, and easy installation, which can meet the diverse equipment connection, control, and data transmission needs in industrial automation scenarios, and provide global technical support and product consulting services.

HMI panel

(1) Core positioning and connection method

Baldor's HMI panel (human-machine interface) serves as a key interaction hub between the machine and the operator, and can seamlessly interface with the Mint motion controller through the controller's RS232 interface or optional CANopen interface (with KPD-OPTC tab installed). Its core advantage lies in the efficient data transmission achieved through the Mint Comms Array (a dedicated storage area in the controller memory), which supports read and write operations of up to 99 data elements. The preset elements can directly present key data such as digital I/O information, axis position, and fault alarms, greatly simplifying the process of equipment status monitoring and parameter adjustment.

(2) Product classification and technical parameters

1. Text display

Basic features: Adopting a reflective LCD screen, in addition to displaying text of different sizes, it also supports simple graphic display, equipped with a data input keyboard and programmable macro keys. Through the keyboard macro editor, a series of instructions such as page flipping, parameter setting, LED switching, etc. can be executed with a single key, without the need for additional programming, making the operation convenient. The LCD display screen can expand the display of data visualization forms such as bitmap, bar chart, trend chart, etc. All functions are programmed and configured through Designer software.

Core model parameters (representative models):

|Model | Display specifications (rows/columns) | Resolution | Number of function keys | numeric keypad | LED status indicator | User memory | Alarm capacity | Protection level | Maximum power consumption (24VDC) | Dimensions (HxL, mm) | Installation opening (LxH, mm)|

|KPD-KG420-10 | 4/20 | 120x32 | 4 | None | 4 | 512KB | 1024 | IP65 |~250mA | 149x109 | 136x96|

|KPD-KG420-20 | 4/20 | 120x32 | 9 | Yes | 10 | 512KB | 1024 | IP65 |~250mA | 149x109 | 136x96|

|KPD-KG420-30 | 4/20 | 120x32 | 12 | Yes | 12 | 512KB | 1024 | IP65 |~300mA | 141x176 | 128x163|

|KPD-KG840-10 | 8/40 | 240x64 | 20 | Yes | 20 | 512KB | 1024 | IP65 |~400mA | 220x176 | 207x163|

Common configuration: All models support 256 user-defined fonts, equipped with 1 CANopen auxiliary port, and the serial port baud rate can be selected as 38400 or 9600; Some high-end models (such as KPD-KG840-10) have printer ports, real-time clock, and battery power supply functions, support 16KB recipe memory, and can store device operating parameter templates to meet multi scenario switching needs.

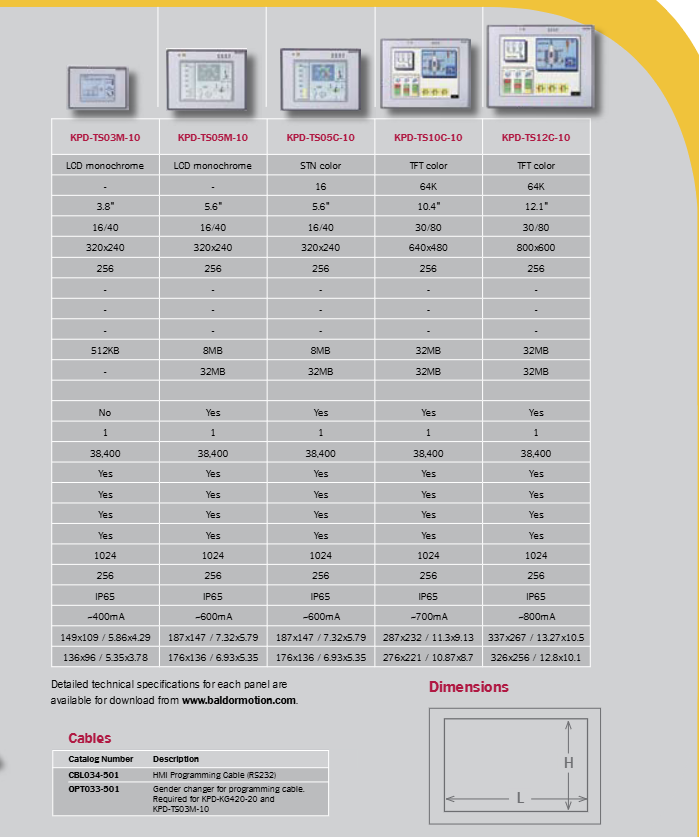

2. Graphic touch screen

Basic features: Covering entry-level to high-end application scenarios, with sizes ranging from 3.8-inch monochrome screens to 12.1-inch full-color TFT screens, resolution range from 320x240 to 800x600, capable of displaying complex graphics, dynamic interfaces, and high-definition data charts. Support formula data storage function, able to save multiple machine configuration parameters for quick calling and switching; The screen can customize touch areas (touch units), respond to human touch operations, and can be programmed to achieve functions such as data input, page switching, and scrolling display.

Core model parameters (representative models):

|Model | Display Type | Size | Color Depth | Display Specifications (Rows/Columns) | Resolution | User Memory | Extended Memory | Real time Clock | Alarm Capacity | Protection Level | Maximum Power Consumption (24VDC) | Dimensions (HxL, mm) | Installation Openings (LxH, mm)|

|KPD-TS03M-10 | LCD Monochrome | 3.8 "| - | 16/40 | 320x240 | 512KB | - | Yes | 1024 | IP65 |~400mA | 149x109 | 136x96|

|KPD-TS05M-10 | LCD Monochrome | 5.6 "| - | 16/40 | 320x240 | 8MB | 32MB | Yes | 1024 | IP65 |~600mA | 187x147 | 176x136|

|KPD-TS05C-10 | STN Color | 5.6 "| 16 Color | 16/40 | 320x240 | 8MB | 32MB | Yes | 1024 | IP65 |~600mA | 187x147 | 176x136|

|KPD-TS10C-10 | TFT Color | 10.4 "| 64K Color | 30/80 | 640x480 | 32MB | 32MB | Yes | 1024 | IP65 |~700mA | 287x232 | 276x221|

|KPD-TS12C-10 | TFT Color | 12.1 "| 64K Color | 30/80 | 800x600 | 32MB | 32MB | Yes | 1024 | IP65 |~800mA | 337x267 | 326x256|

Common configuration: All touch screens support 256 user-defined fonts, with a fixed serial port baud rate of 38400 and equipped with one CANopen auxiliary port; Support password protection function, set operation permissions to prevent accidental operation; Built in 256 event lists for easy device fault tracing and operational status analysis.

(3) Programming software and functional support

Baldor has developed a Windows based Designer software specifically for HMI panels, which serves as a unified programming tool for the entire range of panels, greatly reducing training, development, and maintenance costs. Its core functions include:

Visual editing: Adopting WYSIWYG (what you see is what you get) editing mode, the design effect on the computer screen is completely consistent with the actual display of the panel, and the placement and editing of elements such as text, variables, graphics, touch buttons, etc. are intuitive and efficient.

Rich resource library: Built in 500+professional symbol libraries, which can be directly called to quickly build interfaces; Support custom graphic creation, or import image files in more than 20 formats such as BMP, JPEG, TIFF, etc., to meet personalized interface design needs.

Multilingual translation: Project text, alarm information, operation prompts, etc. can be exported to Microsoft Excel and other office software for multilingual editing. After editing, the project file can be imported, and the graphic layout remains intact without the need for readjustment.

Object oriented workflow: Screen images exist in the form of objects, supporting movement, copying, editing, alignment, and combination operations. Custom graphics can be saved to the project library for easy reuse in subsequent projects.

Touch unit programming: The touch area can be defined by software drawing or importing graphic files, combined with a keyboard macro editor, to achieve complex logic control and operation response, and even overlay touch layers on animated drawings, providing efficient tools for equipment troubleshooting.

Software acquisition: HMI Designer software can be applied for evaluation and use through the Baldor official website (www.baldormotion. com), and detailed programming tutorials and technical documents can also be downloaded from the platform.

Cables and connectors

(1) Product classification and usage

Baldor's cable product system is complete, covering four categories: motion feedback cables, motor power cables, communication cables, and programming cables, all tailored to fit its servo motors, drivers, and motion controllers. It provides two forms of cables: prefabricated products (with connectors) and original cables (without connectors). Some cables support customized lengths to meet the needs of different installation scenarios.

1. Motion feedback cable

Classification and Applications: This includes encoder cables, EnDat cables, Resolvers (rotary transformers) cables, and SSI cables, which correspond to different types of feedback signal transmission requirements. They are suitable for signal connections between Baldor Series II drives, MicroFlex drives, NextMove series motion controllers, and servo motors.

Key specifications:

Encoder cable: Models represented by CBLxxxRF-E (without connectors), CBLxxxSF-E (with connectors at both ends), etc., with a wire diameter of 8.9mm (0.35 inches) and a 16 core wire design;

EnDat cable: Models represented by CBLxxxRF-D (without connector) and CBLxxxSF-D (with motor end connector), with a wire diameter of 8.65mm (0.34 inches) and an 11 core wire design;

Resolver/SI cable: Resolver cable diameter 8.2mm (0.32 inches), 7-core wire; SSI cable supports connection to both ends of MicroFlex driver (model CBLxxxSF-S2);

Suitable for special motors: When used for Baldor stainless steel servo motors (SSBSM), an "S" symbol should be added after the model, such as CBL025SF-E1S.

2. Motor power cable

Core parameters: Divided into four specifications based on rated current: 12A, 20A, 35A, and 50A, corresponding to wire diameters of 10.8mm (0.43 inches), 12.7mm (0.5 inches), 19.2mm (0.76 inches), and 22.8mm (0.9 inches), respectively;

Model examples: CBLxxxRP-12 (12A without connector), CBLxxxSP-20 (20A with motor end connector, model CBLxxxSP-20S when compatible with SSBSM motor);

Length options:

North America: 015 (5ft/1.5m), 030 (10ft/3.0m), 061 (20ft/6.1m), 091 (30ft/9.1m), 152 (50ft/15.2m), 229 (75ft/22.9m), 305 (100ft/30.5m);

Other regions: 025 (2.5m/8.2ft), 050 (5.0m/16.4ft), 075 (7.5m/24.6ft), 100 (10m/32.8ft), 150 (15m/49.2f), 200 (20m/65.6ft).

3. Communication and programming cables

Programming cable:

CBL001-501: RS232 interface, 9-pin D-type connector, length 3m (9.9 feet), used for programming connection between HMI panel and controller;

CBL034-501: HMI dedicated RS232 programming cable;

OPT033-501: Programming cable gender converter, an essential accessory for KPD-KG420-20 and KPD-TS03M-10 HMI panels;

Ethernet/CAN cable: designed specifically for Baldor e100 product series and CAN I/O nodes with RJ45 interface, using CAT5e shielded wires and RJ45 connectors. Core models include CBL002CM-EXS (0.2m/8 inches), CBL005CM-EXS (0.5m/1.6 feet), CBL010CM-EXS (1m/3.2 feet), CBL020CM-EXS (2m/6.5 feet), CBL050CM-EXS (5m/16.3 feet), and CBL100CM-EXS (10m/32.6 feet). The shielding design effectively reduces electromagnetic interference and ensures data transmission stability.

4. Motor connector

Suitable for use with original cables, providing two types of power connectors and feedback connectors:

|Model | Purpose | Suitable Motor Type|

|MCSPOW-08 | Power connector (compatible with BSM 50/63/80 motors) | Ordinary servo motor|

|MCSPOW-08S | Power connector | Stainless steel servo motor (SSBSM)|

|MCSRES-12 | 12 pin feedback connector (Resolve/OnDet/SI) | ordinary servo motor|

|MCSRES-12S | 12 pin stainless steel feedback connector (Resolve/OnDet/SI) | Stainless steel servo motor (SSBSM)|

|MCSENC-16 | 16 pin encoder feedback connector | ordinary servo motor|

|MCSENC-16S | 16 pin stainless steel encoder feedback connector | Stainless steel servo motor (SSBSM)|

(2) Environmental and mechanical characteristics

Baldor motor feedback cables and power cables are designed specifically for high flexibility application scenarios, with excellent bending resistance and resistance to high and low temperatures. The specific parameters are as follows:

Specific parameters of characteristic indicators

Working temperature range bending state: -30 ℃ to 80 ℃; Fixed state: -50 ℃ to 90 ℃

The static bending radius is approximately 7.5 times the diameter of the cable

The dynamic bending radius is approximately 10 times the diameter of the cable

The minimum bending life under rated conditions shall not be less than 2 million times

Maximum operating speed 3m/s (9.8 feet/s)

Maximum acceleration 7m/s ² (0.7G)

Additional explanation: Detailed technical parameters of 35A and 50A specification power cables need to be obtained by contacting Baldor official.

24V DC DIN rail power supply unit

(1) Core positioning and product features

This series of power supply units is designed specifically for Baldor motion controllers, servo drives, and HMI panels. It outputs a stable 24V DC voltage and adopts a DIN rail installation method (compatible with TS35/7.5 or TS35/15 specification rails). It has the following core features:

Wide input range: Some models support 85-264VAC wide voltage input, compatible with global voltage standards of 110-230VAC, and also support 120-370VDC DC input, suitable for different power supply environments;

High efficiency and low consumption: conversion efficiency up to 84%, low operating temperature, excellent heat dissipation performance;

Low interference: Built in EMI filter with low ripple noise (minimum 80mV), reducing electromagnetic interference to other devices;

Multiple protection: equipped with short-circuit protection, overload protection, overvoltage protection, and temperature protection functions to ensure the safe operation of equipment;

Compact and lightweight: With a small size and a minimum weight of only 0.55kg, it saves space for installing control cabinets.

(2) Core model technical parameters

Model Input Voltage Range Output Specification Output Power Conversion Efficiency Ripple Noise Overload Protection Range Overvoltage Protection Range Operating Temperature Range Dimensions (HxLxD, mm) Weight

DR-75-24 85~264VAC; 120~370VDC 24V@3.2A 75W 80% 150mV 115%~150% output current 120%~140% rated output voltage 0 ℃~50 ℃ (100% load); -10 ℃ (80% load); 60 ℃ (60% load) 100x55.5x125.2 0.55kg

DR-120-24 88~132VAC; 176~264VDC 24V@5.0A 120W 84% 80mV 115%~150% output current 120%~150% rated output voltage 0 ℃~50 ℃ (100% load); -10 ℃ (80% load); 60 ℃ (60% load) 100x65.5x125.2 0.7kg

DRP-240-24 85~264VAC; 120~370VDC 24V@10.0A 240W 84% 80mV 105%~150% output current 120%~150% rated output voltage 0 ℃~50 ℃ (100% load); -10 ℃ (80% load); 70 ℃ (70% load) 125.5x100x125.2 1.1kg

(3) System Selection Guide

According to the device configuration requirements, the following selection criteria can be used to select the appropriate power supply unit:

Power model adaptation system configuration (HMI+NetMove controller+number of servo axes)

DR-75-24 1 HMI+1 controller+3 servo axes

DR-120-24 1 HMI+1 controller+5 servo axes

DRP-240-24 1 HMI+1 controller+9 servo axes

(4) Safety and Compliance Standards

Safety standards: comply with UL508 and TUV EN60950 certification standards;

EMC standard: meets EN55022 Class B、EN61000-3-2、EN61000-3-3、EN61000-4-2/3/4/5/6/8/11、ENV50204 According to standards, it has excellent electromagnetic compatibility.

Other core accessories

(1) Encoder allocator

Function positioning: Receive a single encoder input signal (usually from the main encoder) and distribute the signal to multiple drivers or motion controllers, suitable for multi device collaborative control scenarios, simplifying encoder signal wiring.

Core model:

|Model | Number of Channels | Installation Method|

|OPT029-501 | 4-channel | DIN rail installation|

|OPT029-502 | 8-channel | DIN rail installation|

(2) EMC filter

Function positioning: Designed specifically for Baldor servo drives and motion controllers to suppress electromagnetic interference and ensure stable operation of equipment in complex electromagnetic environments; The single-phase driver is compatible with a bottom mounted filter (model identification marked with "*"), which can effectively save control cabinet space.

Selection Guide (Classified by Drive Type):

Series II driver adaptation filter:

|Rated current | 230VAC 1 Ø | 115VAC 1 Ø | 230VAC 3 Ø | 230-460VAC 3 Ø|

| 2.5A | FI0029A00*、FI0015A00 | FI0015A00 | - | FI0018A00 |

| 5A | FI0029A00*、FI0015A02 | FI0015A02 | - | FI0018A00 |

| 7.5A | FI0029A00* | FI0029A00 | - | FI0018A00 |

| 15A | - | - | FI0018A01 | FI0018A01 |

| 20A | - | - | - | FI0018A01 |

| 27.5A | - | - | - | FI0018A01 |

MicroFlex series driver adapter filter:

|Rated current | 230VAC 1 Ø | 115VAC 1 Ø | Other specifications|

| 3A | FI0029A00*、FI0015A00 | FI0015A00 | FI0018A00 |

| 6A | FI0029A00* | FI0015A02 | FI0018A02 |

| 9A | FI0029A00* | - | FI0018A03 |

Key model parameters:

|FI0014A00 | 24V 1 Φ | 3.0A | 40x85x54 (1.57x3.35x2.13 inches) | 0.3 (0.66 pounds)|

|FI0029A00 * | 230VAC 1 Φ | 22A | 40x255x100 (1.57x10.04x3.94 inches) | 3 (6.6 pounds)|

|FI0015A00 | 230VAC 1 Φ | 6.0A | 46x114x58 (1.81x4.49x2.28 inches) | 0.5 (1.1 pounds)|

|FI0015A02 | 230VAC 1 Φ | 12.0A | 58x156x46 (2.28x6.14x1.81 inches) | 0.7 (1.5 pounds)|

|FI0018A00 | 480VAC 3 Φ | 7.7A | 71x190x40 (2.8x7.48x1.57 inches) | 0.5 (1.1 pounds)|

|FI0018A01 | 480VAC 3 Φ | 32.9A | 85x270x50 (3.35x10.63x1.97 inches) | 1.2 (2.65 pounds)|

|FI0018A03 | 480VAC 3 Φ | 17.5A | 70x250x45 (2.76x9.84x1.77 inches) | 0.8 (1.76 pounds)|