K-WANG

Zygo NewView 9000 3D Optical Profilometer Technology

Zygo NewView 9000 3D Optical Profilometer Technology

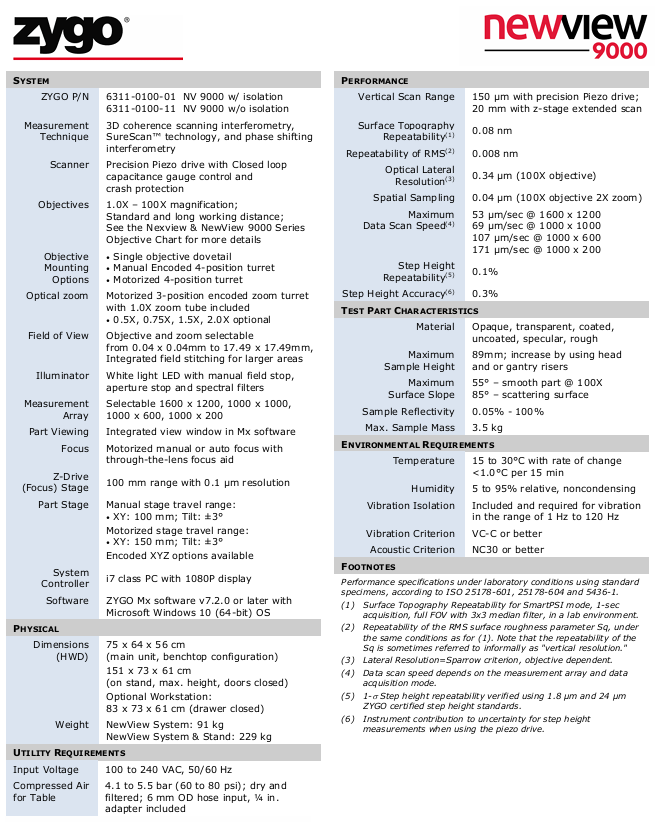

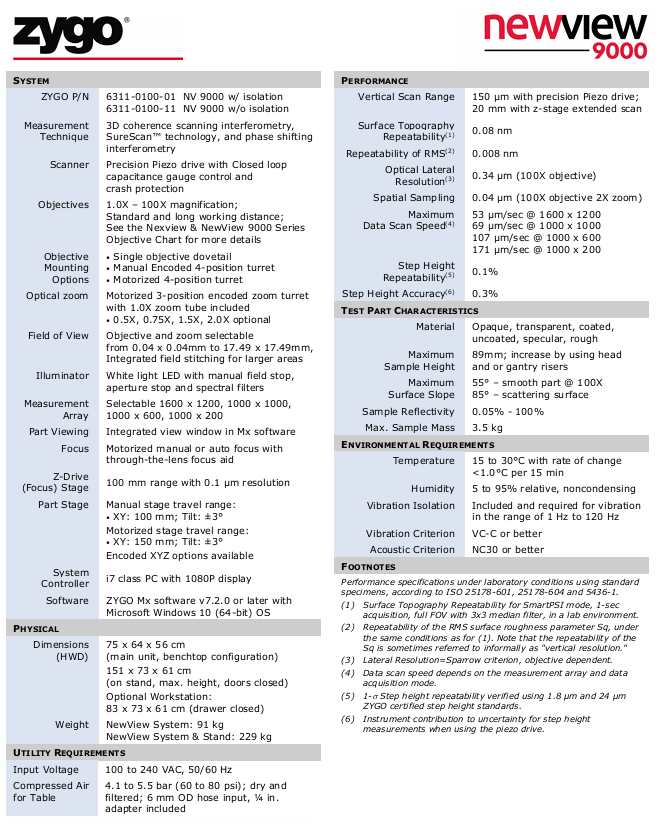

Basic information and model differentiation

1. Core model

The NewView 9000 system offers two basic configurations, with the core difference being whether it includes vibration isolation components:

Model (ZYGO P/N) Configuration Description Applicable Scenarios

6311-0100-01 Vibration sensitive environment with isolation system (such as laboratory multi equipment area, precision manufacturing workshop)

6311-0100-11 scenarios without isolation system (w/o isolation) equipped with external isolation platform (such as dedicated optical laboratory)

2. Principles of Measurement Technology

Adopting 3D Coherence Scanning Interferometer technology combined with Zygo's patented SureScan ™ Technology and Phase Shifting Interferometry enable non-contact surface height data acquisition:

Advantages: Balancing "large scanning range" and "high vertical resolution", it can measure various surfaces such as transparent/opaque, smooth/rough, etc., without the need for sample pretreatment.

Core hardware configuration

The hardware of NewView 9000 is designed around "high-precision optical imaging+flexible motion control", and the key component parameters are as follows:

1. Optical system

(1) Objective lens and zoom component

Specific parameter characteristics of components

Objective magnification: 1.0X -100X;

Type: Standard working distance, long working distance (optional);

Adaptability: Please refer to the "Nexview&NewView 9000 Series Objective Lens Chart" to cover requirements ranging from "low magnification for large field of view" to "high magnification for small field of view". Long working distance objective lenses are suitable for thick samples/complex fixtures

There are three options for installing the objective lens:

1. Single objective dovetail groove;

2. Manual Encoded 4-position Turret;

3. Motorized 4-position turret: The motorized turret supports automated objective lens switching and is suitable for batch sample measurement; Manual turntable has lower cost and is suitable for fixed scenarios

Optical zoom standard configuration: electric 3-digit coded zoom turntable (including 1.0X zoom tube);

Optional: 0.5X, 0.75X, 1.5X, 2.0X zoom components with zoom and objective lens to expand the field of view, coding design ensures repeatability of zoom position

(2) Field of view and lighting

Field of View Range: 0.04 × 0.04mm (high magnification objective+high zoom)~17.49 × 17.49mm (low magnification objective+low zoom), supports integrated field stitching, and can measure large-sized samples beyond the field of view;

Lighting system: White LED light source, equipped with manual field stop, aperture stop, and spectral filter, adjustable lighting intensity and spectral range, suitable for different reflectivity samples.

(3) Image acquisition

Measurement array (pixels): 4 options -1600 × 1200 (high-resolution), 1000 × 1000, 1000 × 600, 1000 × 200 (high-speed acquisition);

Sample observation: The Mx software has an integrated view window built-in, which displays sample images in real-time and assists in focusing and area positioning.

2. Motion control system

(1) Z-axis drive (focusing and scanning)

Component parameter function

Precision piezoelectric drive vertical scanning range: 150 μ m;

Control method: Closed loop capacitance gauge;

Safety design: including crash protection for high-precision vertical scanning, obtaining surface height data, and capacitance gauge to ensure scanning accuracy

Z-axis focusing stage stroke: 100mm;

Resolution: 0.1 μ m;

Focusing method: Electric manual/automatic focusing (with bandpass mirror focusing assistance) used for rough focusing and large height range adjustment of samples, with automatic focusing function improving operational efficiency

(2) Sample stage

Provide two configurations of "manual" and "electric" to meet different automation needs:

Stage type XY axis stroke tilt range (Tilt) Additional functions

Manual stage 100mm ± 3 ° foundation positioning, low cost

Electric stage 150mm ± 3 ° supports automated multi position measurement, with optional "coded XYZ" configuration to improve positioning repeatability

3. System control and software

Control computer: i7 processor, 1080P monitor;

Operating System: Microsoft Windows 10 (64 bit);

Software: ZYGO Mx v7.2.0 and above versions, supporting data acquisition, 3D/2D visualization, roughness analysis (such as Sq, Ra), step height calculation, and other functions.

Key performance indicators (under laboratory conditions)

The performance parameters are based on ISO standards (25178-601, 25178-604, 5436-1) and validated using standard samples. The core indicators are as follows:

Performance category specific parameter notes

Vertical scanning range of 150 μ m (piezoelectric drive); 20mm (Z-axis extended scan) extended scan suitable for large step height samples (such as 20mm thick samples)

Surface morphology repeatability (1) 0.08nm SmartPSI mode, 1-second acquisition, full field of view+3 × 3 median filtering

RMS roughness (Sq) repeatability (2) 0.008nm, also known as "vertical resolution", reflects the accuracy of surface detail measurement under the same measurement conditions as described above

Optical lateral resolution (3) 0.34 μ m (100X objective) Based on the Sparrow criterion, the higher the objective magnification, the higher the lateral resolution

Data scanning speed (4) 171 μ m/s (1000 × 200 array) The speed varies with the "measurement array size" and "acquisition mode", and the small array is suitable for high-speed measurement

Step height repeatability (5) 0.1% (1 σ) verified with Zygo certified step standard parts at 1.8 μ m and 24 μ m

Step height accuracy (6) 0.3% with instrument contribution only uncertainty, based on piezoelectric drive measurement

Sample adaptation range

NewView 9000 supports multiple types of samples and adapts parameters covering key dimensions such as material, size, and surface characteristics

Description of sample characteristic adaptation parameters

Material: opaque (metal, silicon wafer), transparent (glass, polymer), coated/uncoated, smooth/rough surface. White LED and filter are compatible with low reflectivity samples (minimum reflectivity of 0.05%)

The maximum height of the sample is 89mm; it can be expanded through the "lens holder/gantry risers". Attention should be paid to the working distance of the objective lens to avoid collision between the sample and the objective lens

Smooth surface slope: maximum 55 ° (100X objective lens);

Scattering surface: Suitable objective lens should be selected for high slope samples with a maximum angle of 85 ° to avoid data loss

The maximum sample weight is 3.5kg to protect the accuracy of the stage movement. For overweight samples, customized load-bearing components are required

Environmental requirements

To ensure measurement accuracy, the following environmental conditions must be met, with core control of "temperature, vibration, acoustics" interference:

Purpose of environmental category requirements

Temperature 15-30 ° C; temperature change rate<1.0 ° C/15 minutes to avoid material thermal deformation affecting the optical system and sample

Humidity 5% -95% relative humidity, non condensing to prevent condensation of optical components and rusting of metal parts

Vibration isolation comes standard with a vibration isolation system (model 6311-0100-01);

Vibration range: 1Hz-120Hz;

Vibration standard: It is required to meet the requirement that vibration of VC-C level or above will cause interference fringes to blur, affecting the accuracy of height data

Acoustic environment NC30 level or above (noise ≤ 30 decibels) to avoid the transmission of sound wave vibrations to equipment and interference with precision moving components

Core notes and applicable scenarios

Timeliness of specifications: Technical parameters may change without prior notice, and actual configuration should be based on the latest official Zygo documentation;

Applicable scenarios:

Research field: Surface roughness of MEMS devices, microstructure step height, and surface morphology analysis of biomaterials;

Industrial field: semiconductor wafer flatness, optical component surface shape error, precision mold surface quality inspection;

Calibration requirements: Zygo certified standard parts (such as step height standard parts, reference planes) need to be calibrated regularly to ensure stable performance indicators.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector