K-WANG

Watlow PM PLUS ™ 6 Series PID Integrated Controller

Watlow PM PLUS ™ 6 Series PID Integrated Controller

Product core positioning and basic information

1. Core positioning

A multifunctional integrated controller that supports PID control, limit protection, ramp/soak programming, multi protocol communication, and other functions. It can adapt to various process parameter controls such as temperature, pressure, and flow, and is widely used in industrial heating, cooling, and mixed processes.

2. Basic specifications

Dimensions: 1/16 DIN standard panel installation

Power supply range: high voltage (85-264VAC), low voltage (12-40VDC/20-28VAC), some models include 2 digital I/O channels

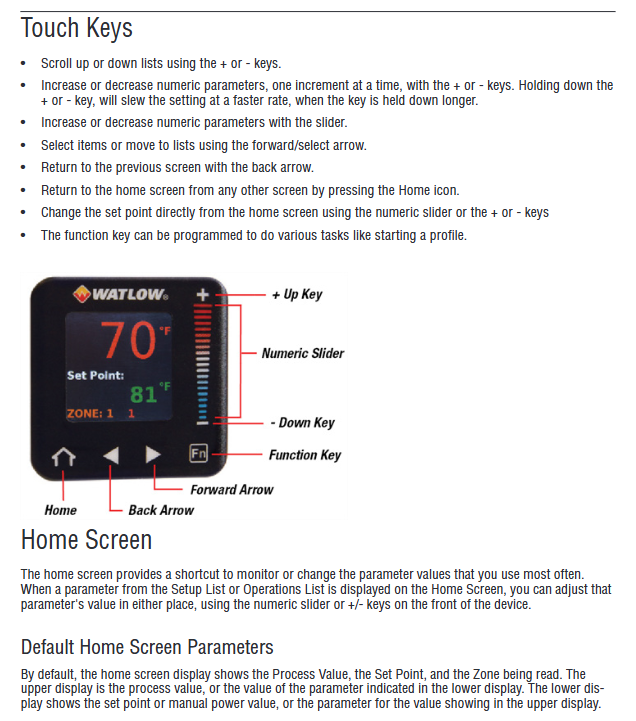

Display and operation: LCD display screen+smooth touch keyboard, supports programmable function keys, IP67 protection level (front panel)

Certification standard: UL ®、 CSA, CE, RoHS, FM, etc., some models support use in Class 1, Div. 2 hazardous areas

3. Warranty and Support

Warranty period: 3 years (for first-time buyers, not for misuse scenarios)

Technical support: can be provided through local representatives or email( wintechsupport@watlow.com )Or call (+1 (507) 494-5656) for assistance

Return policy: RMA number must be applied for in advance, and repair or replacement will be processed according to the warranty terms

Core functions and technical features

1. Input/output configuration

(1) Input type

Universal inputs: thermocouple (11 types including J/K/T/E), RTD (2/3 wire system, 100 Ω/1k Ω), thermistor (5k-40k Ω)

Process input: 0-20mA, 0-10VDC, 0-50mV, 1k Ω potentiometer, supports 10 point linearization calibration

Special inputs: current transformer (0-50mA), remote set point input, sensor backup (dual input redundancy)

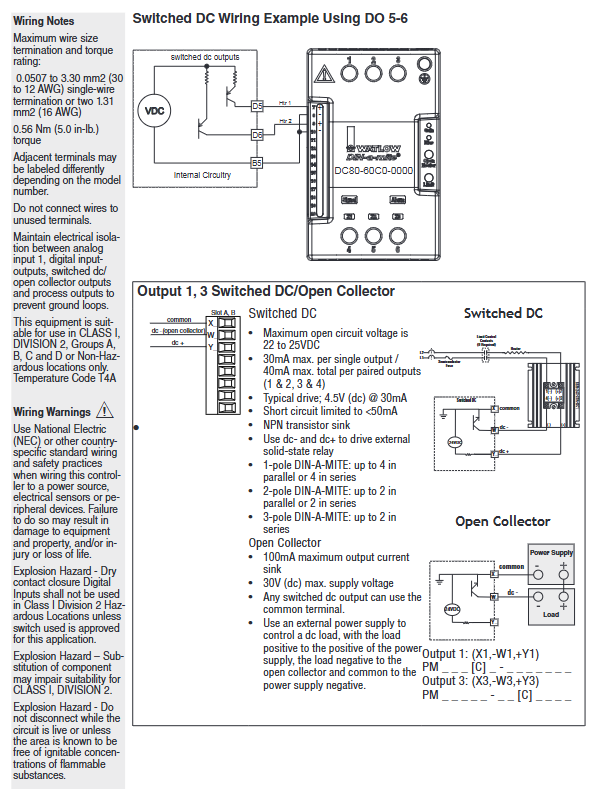

(2) Output type

Switch output: DC switch/open collector, 5A mechanical relay (Form A/C), 15A NO-ARC relay (extended life), 0.5A solid-state relay (SSR)

Process output: 0-10VDC/0-20mA universal process output, supporting parameter retransmission function

Output functions: heating/cooling control, alarm triggering, event output, timer linkage, etc

2. Control function

Control algorithm: Supports On Off, P, PI, PD, PID control, built-in TRU-TUNE+adaptive tuning algorithm and Auto Tune automatic calibration

Special controls: ratio control, difference control, square root conversion, wet bulb/dry bulb humidity calculation, compressor control, electric valve control

Limit protection: Integrated high and low temperature limit controller, supports manual/automatic reset, ensuring equipment and personnel safety

Slope/constant temperature programming: 4 program files, a total of 40 steps, supporting step types such as time/rate mode, waiting for events (digital input/process value), jump loop, etc

3. Communication and Data Interaction

Supporting protocol: Modbus ® RTU/TCP、EtherNet/IP ™、 DeviceNet ™、 PROFIBUS DP, J1939 CAN bus, some models include Bluetooth (EZ-LINK) ™ Remote configuration of app

Communication features: EIA-485/232 interface, supports up to 247 Modbus nodes, maximum communication distance of 1200 meters

Data retransmission: Process values/setpoints can be retransmitted to recorders or other controllers through analog outputs

4. Safety and protective features

Electrical safety: Double insulation design, touch safe terminals, anti ESD static interference

Fault detection: sensor open/short circuit detection, heater fault (current detection), open-loop detection (no process response alarm)

Alarm function: 4-channel independent alarm (high/low/deviation alarm), supporting latch/non latch, delayed triggering, and alarm shielding

Installation and Configuration Guide

1. Installation process

Panel opening: 44.96-45.47mm (width) × 53.3mm (height), distance between adjacent devices ≥ 21.6mm

Fixing method: Fix from the back of the panel through installation rings and brackets, with a torque of 3-4 in lbs

Wiring specifications: Supports 12-30 AWG wires, terminal torque 5.0 in lb, must comply with electrical standards such as NEC, and use certified switches in hazardous areas

2. Core configuration steps

Quick Start: The default configuration is J-type thermocouple input, heated PID control, with a set point of 75 ° F, which can be directly modified through the panel

Parameter configuration: Supports local panel configuration EZ-LINK ™ App Bluetooth configuration, COMPOSER/CONFIGURATOR software configuration

Key configuration items: input sensor type, control algorithm, output function allocation, communication protocol parameters, alarm threshold, program steps, etc

3. Programming (Ramp/Soak)

Global settings: First configure the slope type (time/rate), program type (set point/process value trigger), and soaking deviation zone

Step editing: Supports step types such as time/soaking/waiting for events/jumping, and can set target values, duration, and event output status

Startup mode: manual panel start, function key trigger, digital input trigger, remote communication start

Key points for operation and use

1. Basic operations

Main screen: displays process values, set points, and area numbers, supports direct sliding to modify set points

Operating modes: automatic (closed-loop control), manual (open-loop power output), shutdown (output off)

Event response: When an alarm/limit is triggered, the screen alternately displays normal data and event information, which can be cleared or muted through the panel

2. Advanced Operations

Optimization function: Auto Tune automatically calculates PID parameters, TRU-TUNE+adaptive optimization dynamic process control

Parameter backup: can save 2 sets of user configurations, supports restoring factory settings or user-defined settings

Security lock: Supports 5 levels of read and write permission grading, and can enable password protection (user password+administrator password) to prevent accidental operations

3. Maintenance points

Regular calibration: Input offset calibration, linearization curve calibration, it is recommended to use a precision signal source for verification

Cleaning and maintenance: The touch keyboard needs to be cleaned with a dry cloth to avoid corrosive cleaning agents

Fault record: Regularly check alarm history and fault logs for easy troubleshooting of duplicate issues

Typical application scenarios

Single loop temperature control: Temperature is collected through thermocouples/RTDs to drive heaters/refrigerators to maintain the set point, suitable for industrial ovens and reaction vessels

Sensor backup control: dual input redundancy, automatically switches to backup sensor in case of main sensor failure, ensuring continuous operation

Ratio control: maintaining a fixed ratio of two process parameters (such as fuel/air mixture ratio), suitable for combustion systems

Slope/constant temperature process: multi-step temperature curve control (such as heating insulation cooling), suitable for material heat treatment and food processing

Wet bulb/dry bulb humidity control: calculates relative humidity through dual temperature sensors, drives humidification/dehumidification equipment, suitable for environmental testing chambers

Troubleshooting and Common Problems

1. Core fault handling

Alarm cannot be cleared: Check if the latch function is enabled, manually clear it after the process value returns to the safe range

No output action: Confirm the control mode, output function allocation, wiring correctness, and troubleshoot load/fuse faults

Communication failure: Verify address, baud rate, parity parameters, check wiring polarity and terminal resistance (120 Ω)

Control accuracy deviation: Re execute Auto Tune, check the sensor installation position, and adjust the filtering time constant

2. Common error codes

Input Error: Sensor open/short circuit or type configuration error

Limit High/Low: The limit value is triggered and needs to be reset or the threshold adjusted

Loop Open Error: Open loop detection triggered, process value unresponsive (such as heater failure)

Heater Error: Abnormal current of heater (too high/too low), check the load or current transformer

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923